Novel liquid organopolysiloxane and uses thereof

A polysiloxane and organic technology, applied in the field of new liquid organopolysiloxane, which can solve the problems of unknown use of liquid organopolysiloxane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

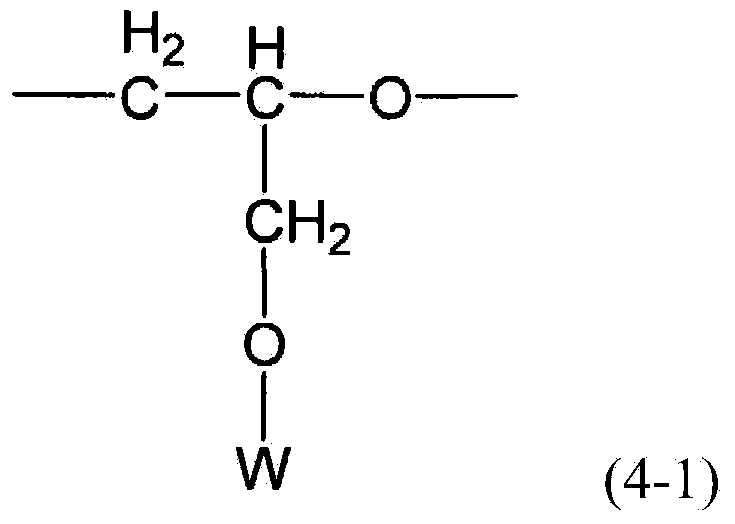

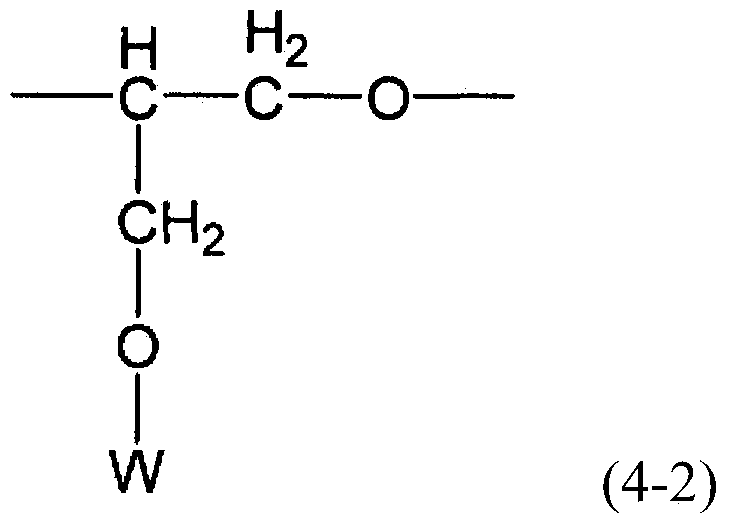

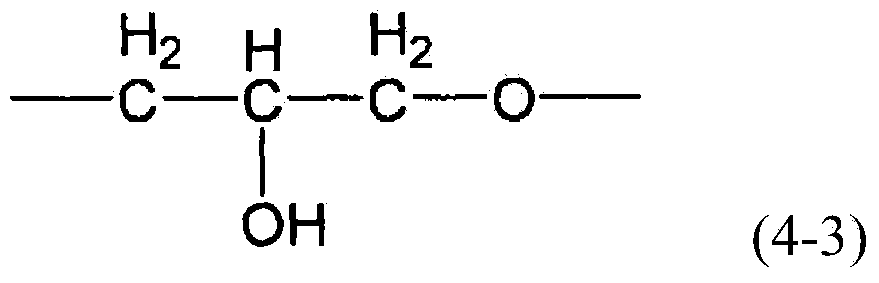

Method used

Image

Examples

preparation example Construction

[0483] Any crosslinked organopolysiloxane can be used without limitation on the physical mode or production method (such as dilution), properties, etc., provided it is a crosslinked organopolysiloxane such as those described above. Particularly preferred examples thereof include α,ω-diene crosslinked silicone elastomers described in U.S. Patent No. 5,654,362 (commercially available products include DC 9040 silicone elastomer blend, DC 9041 Silicone Elastomer Blend, DC 9045 Silicone Elastomer Blend, DC9046 Silicone Elastomer Blend, EL-9140 DM Silicone Elastomer Blend, 9546 Silicone Elastomer Blend, 9027 Organic Silicone Elastomer Blend, FB-9586 Silicone Elastomer Blend, and EL-8040 ID Silicone Organic Blend). In addition, examples of partially crosslinked organopolysiloxane polymers include: (Dimethicone / Vinyl Dimethicone) Crosspolymer, (PEG-8 to 30 / C6 to C30 Alkyl Dimethicone) Crosspolymer, (Vinyl Dimethicone / C6 to C30 Alkyl Dimethicone) Crosspolymer cross-linked polymer, (p...

example

[0523] Hereinafter, the present invention is described in detail with reference to Examples. It should be understood that the present invention is not limited by these examples. In the following composition formulas, "M" means Me 3 SiO group (or Me 3 Si group), "D" means Me 2 SiO group, "M H " means Me 2 HSiO group (or Me 2 HSi group), "D H "Denotes a MeHSiO group, and "M R " and "D R " respectively represent the units wherein the methyl groups in M or D are modified by substituents.

[0524] Note that in the following practical examples and comparative examples, "preparation of organosilicon compound No. X" and the like are written for convenience, and the obtained product is in the form of a mixture containing a small amount of unreacted raw materials and the like in addition to the main components .

[0525] Practice example 1

[0526]

[0527] 137.7 Methylhydrogenpolysiloxane represented by the average composition formula: MD 42.9 D. H 6.7 M and 14.9 g...

example 1

[0618] Formulation Example 1: Emulsion Foundation

[0619] (Component) (weight%)

[0620] 1. Decamethylcyclopentasiloxane 27.0

[0621] 2. Dimethicone (6cSt) 2.0

[0622] 3. Methyl polytrimethicone (M3T) 2.0

[0623] 4.Organosilicon compound No.12.0

[0624] 5. Propylene Glycol 10.0

[0625] 6. Ion exchanged water 30.0

[0626] 7. Sodium L-aspartate 2.0

[0627] 8. Dextrin Palmitate Treated Titanium Dioxide 10.0

[0628] 9. Dextrin palmitate treated mica 12.0

[0629] 10. Dextrin Palmitate Treated Talc 2.0

[0630] 11. Dextrin Palmitate Treated Iron Oxide 1.0

[0631] 12. Parabens in moderation

[0632] 13. Antioxidants in moderation

[0633] 14. Appropriate amount of spices

[0634] Preparation

[0635] A: Components 1 to 4 and components 12 and 13 were heated and dissolved at 50°C. Then, components 8 to 11 were added and dispersed by stirring.

[0636] B: Components 5 to 7 and Component 14 were mixed and dissolved by stirring at 70°C.

[0637] C: Bring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com