High-voltage mono-crystal lithium nickel cobalt manganese oxide anode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the field of lithium-ion batteries, can solve problems such as cycle performance needs to be improved, product consistency is difficult to guarantee, cycle performance is not mentioned, etc., and it is convenient for large-scale production, room temperature and high temperature Excellent cycle performance, high temperature capacity retention and improved capacity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

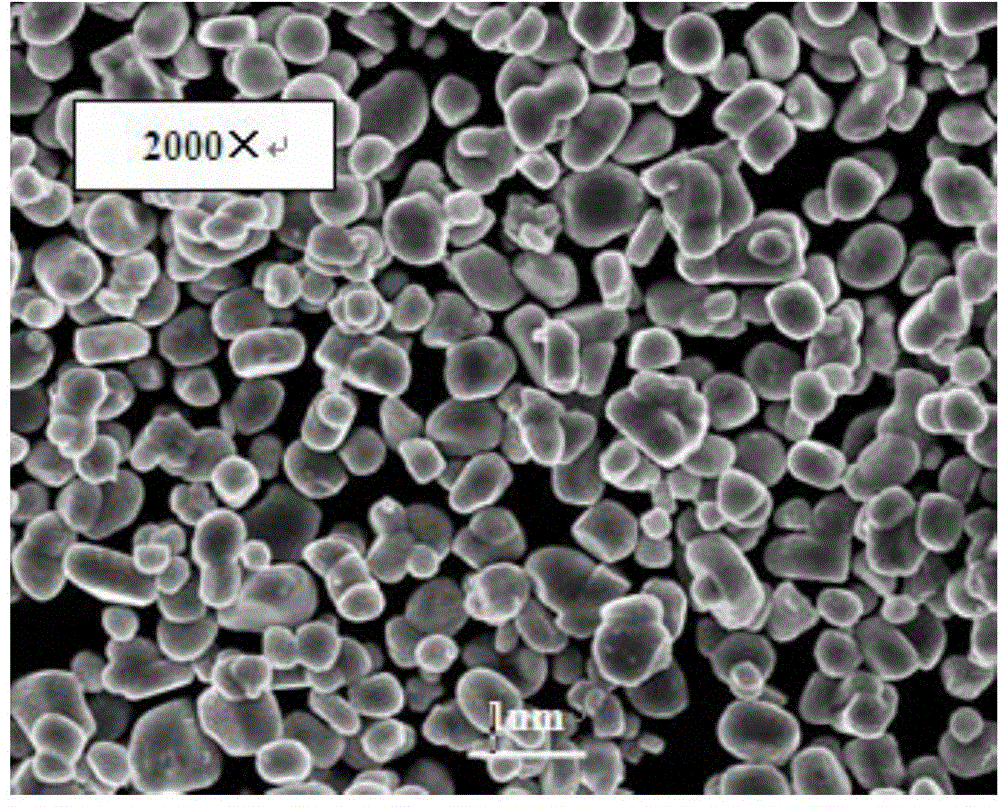

[0029] 1) Nickel sulfate, cobalt sulfate, and manganese sulfate are dissolved in deionized water at a ratio of 5:2:3 by Ni, Co, and Mn to prepare a mixed salt solution with a total concentration of metal cations of 1.2mol / L, 200kg in total, And add 0.2kg of aluminum sulfate, stir to make it fully mixed to obtain a mixed salt solution.

[0030] 2) Prepare 5mol / L sodium hydroxide solution and 3mol / L ammonia water respectively, then pump the prepared solution into the reaction kettle separately at a rate of 0.4L / h and stir, while controlling the sodium hydroxide and ammonia water The flow rate of the aqueous solution is such that the pH value of the mixed solution is 9.7, and the temperature of the reaction kettle is controlled at 45°C during the process; the stirring speed is 300rpm, and the mixed salt solution to be prepared is added into the reaction kettle and continued to stir and age for 12h, and then the obtained The solid-liquid mixture was separated by centrifugal filtra...

Embodiment 2

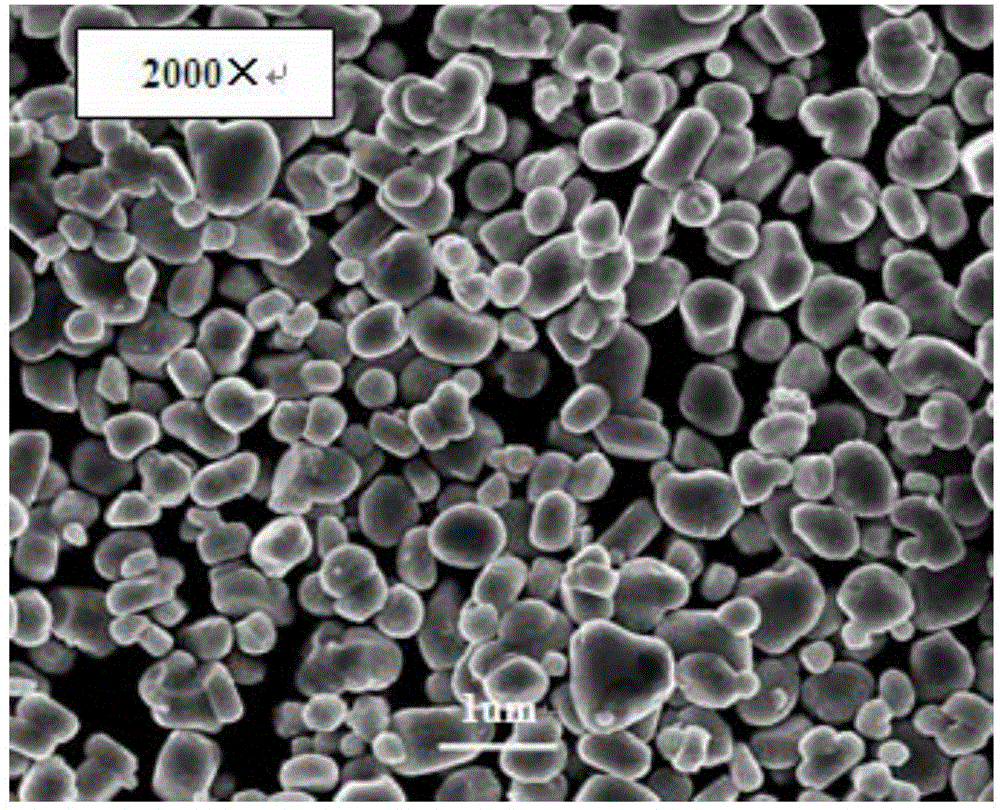

[0035] 1) Nickel nitrate, cobalt nitrate, and manganese nitrate are dissolved in deionized water at a ratio of 1:1:1 by Ni, Co, and Mn to form a salt solution with a total concentration of metal cations of 1.4mol / L, 200kg in total, and Add 0.1 kg of zirconium nitrate, stir to make it fully mixed to obtain a mixed salt solution.

[0036] 2) Prepare 4mol / L sodium hydroxide solution and 4mol / L ammonia water respectively, then pump the prepared solution into the reaction kettle separately at a rate of 0.6L / h and stir, while controlling the sodium hydroxide and ammonia water The flow rate of the aqueous solution is such that the pH value of the mixed solution is 9.2, and the temperature of the reaction kettle is controlled at 60°C during the process; the stirring speed is 400rpm. After adding all the prepared salt solution into the reaction kettle, continue to stir and age for 16h, and then the obtained solid-liquid mixture After separation by centrifugal filtration, the solid was ...

Embodiment 3

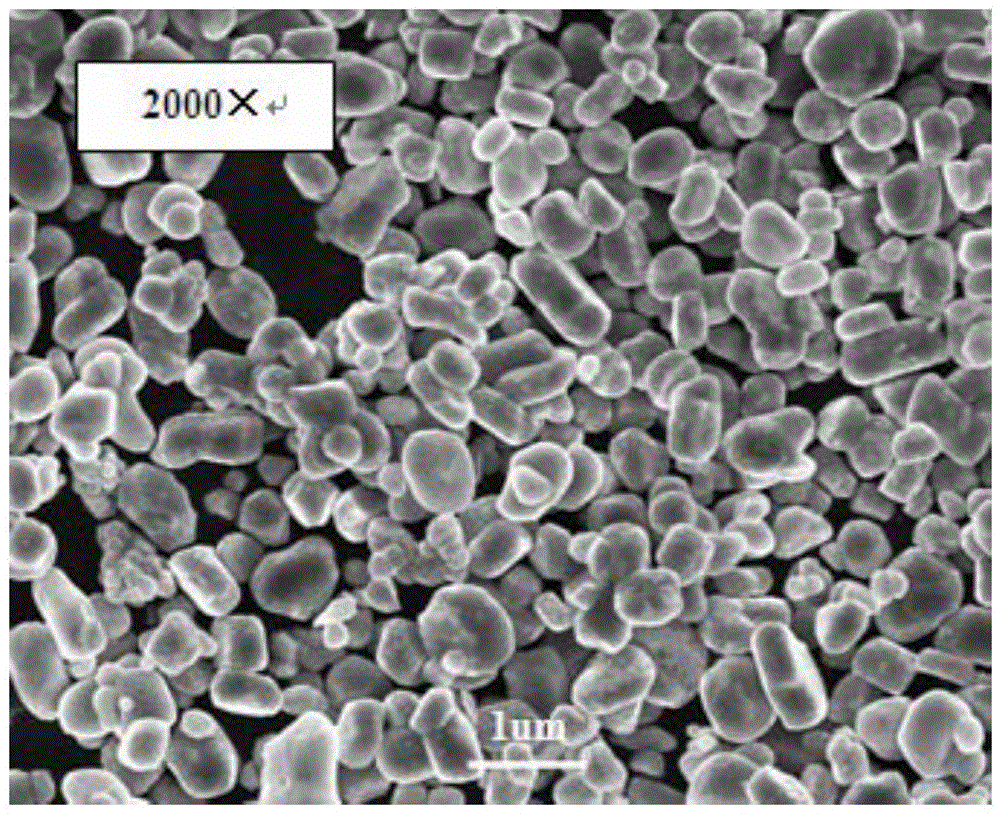

[0041] 1) Nickel nitrate, cobalt nitrate, and manganese nitrate are dissolved in deionized water in a ratio of 5:2:3 by Ni, Co, and Mn to prepare a salt solution with a total metal cation concentration of 1.8mol / L, 200kg in total, and Add 0.2kg, stir to make it fully mixed to obtain a mixed salt solution.

[0042] 2) Prepare 3mol / L sodium hydroxide solution and 5mol / L ammonia water respectively, then pump the prepared solution into the reaction kettle separately at a rate of 0.7L / h and stir, while controlling the sodium hydroxide and ammonia water The flow rate of the aqueous solution is such that the pH value of the mixed solution is 9.8, and the temperature of the reaction kettle is controlled at 70°C during the process; the stirring speed is 200rpm, and all the salt solution to be prepared is added to the reaction kettle and continued to stir and age for 8 hours, and then the obtained solid-liquid mixture Separation by centrifugal filtration, washing the solid with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com