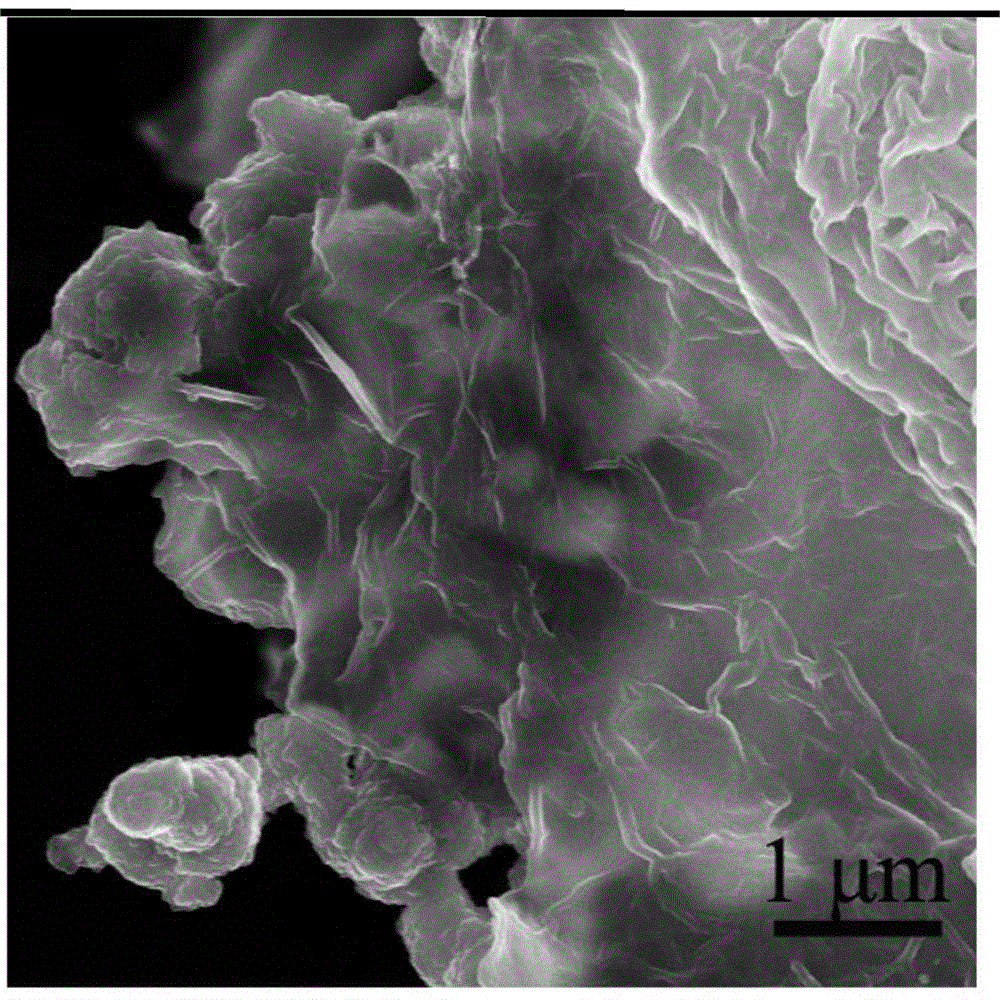

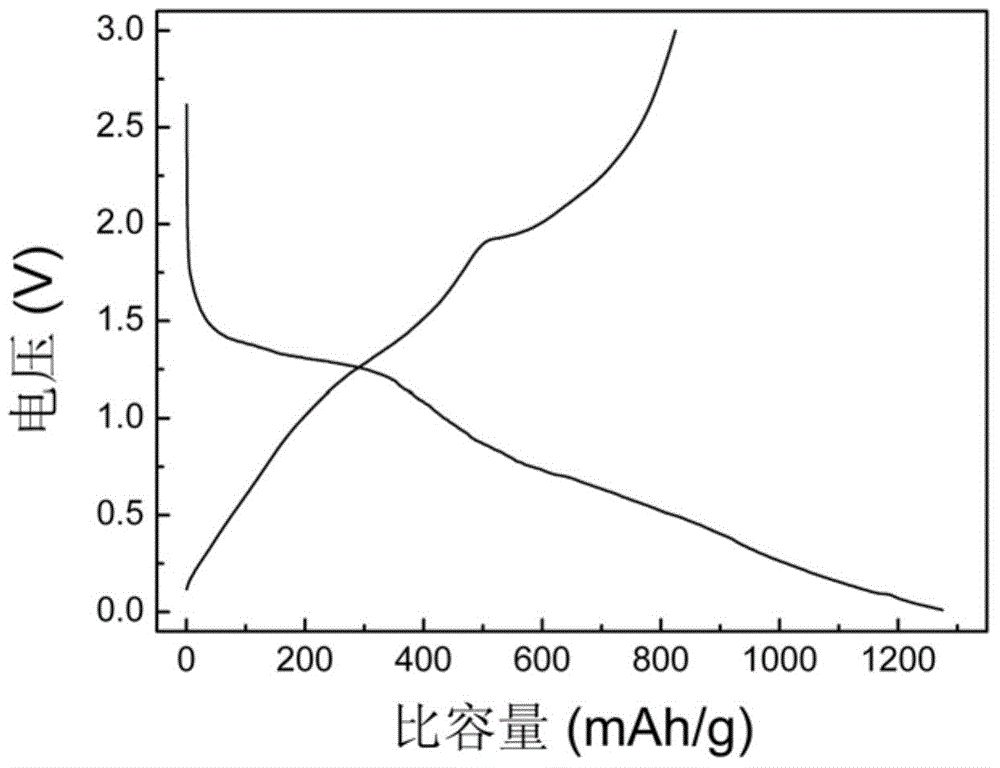

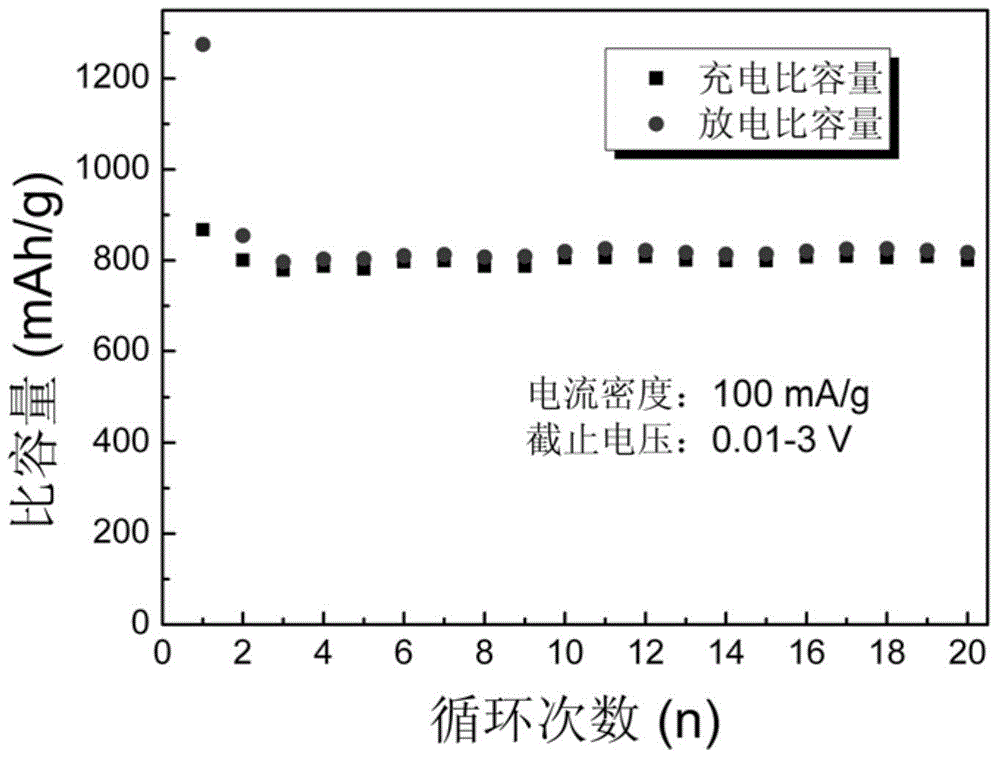

Nano-NiS/graphene composite anode material and preparation method thereof

A graphene composite and positive electrode material technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of complex process, poor controllability, high energy consumption, etc., and achieve simple preparation process, inhibition of dissolution, The effect of a good conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.3 g Ni(CH 3 COO) 2 4H 2O, 0.5 g of trisodium citrate was dissolved in 70 ml of deionized water, stirred evenly to form a green clear solution, weighed 0.2 g L-cysteine and added to the solution, stirred evenly to form a brownish yellow clear solution, and ammonia was added to the solution , so that the pH of the solution was adjusted to 13, and finally the obtained red clear solution was poured into a 100 ml polytetrafluoroethylene-lined hydrothermal kettle at 120 o C for 12 h. The obtained product was centrifuged and washed with deionized water and ethanol, and finally the obtained powder was ultrasonically dispersed in a mixture of 40 ml deionized water and 20 ml ethanol, and 0.1 ml APTES was added to modify the surface of NiS to make it The surface is positively charged, and this solution is labeled solution A;

[0032] Weigh 10 mg graphene oxide (GO) powder and ultrasonically disperse it in a mixed solution of 70 ml deionized water and 10 ml ethanol, a...

Embodiment 2

[0035] Weigh 0.5 g Ni(CH 3 COO) 2 4H 2 O, 0.5 g of trisodium citrate was dissolved in 70 ml of deionized water, stirred evenly to form a green clear solution, weighed 0.5 g L-cysteine and added to the solution, stirred evenly to form a brown-yellow clear solution, and ammonia was added to the solution , adjust the pH of the solution to 8 and stir for 1 h, and finally pour the obtained red clear solution into a 100 ml polytetrafluoroethylene-lined hydrothermal kettle at 160 o C for 20 h. The obtained powder particles were separated and washed with deionized water and ethanol, and finally ultrasonically dispersed in a mixture of 50 ml deionized water and 10 ml ethanol, and 0.6 ml APTES was added to modify the surface of NiS so that the surface was covered with Positive charge, this solution is marked as solution A;

[0036] Weigh 50 mg graphene oxide (GO) powder and ultrasonically disperse it in a mixed solution of 50 ml deionized water and 50 ml ethanol, and this solution...

Embodiment 3

[0039] Weigh 0.4 g Ni(CH 3 COO) 2 4H 2 O, 0.5 g of trisodium citrate was dissolved in 70 ml of deionized water, stirred evenly to form a green clear solution, weighed 0.9 g L-cysteine and added to the solution, stirred evenly to form a brownish yellow clear solution, and ammonia was added to the solution , the pH of the solution was adjusted to 10 and stirred for 1 h, and finally the obtained red clear solution was poured into a 100 ml hydrothermal kettle with a Teflon liner, at 180 o C for 36 h. The obtained powder particles were separated and washed with deionized water and ethanol, and finally ultrasonically dispersed in a mixture of 40 ml deionized water and 20 ml ethanol, and 0.1 ml APTES was added to modify the surface of NiS, so that the surface was covered with Positive charge, this solution is marked as solution A;

[0040] Weigh 30 mg graphene oxide (GO) powder and ultrasonically disperse it in a mixed solution of 30 ml deionized water and 50 ml ethanol, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com