Preparation method for magnetic nanoparticles coated with highly ordered mesoporous carbon

A magnetic nanoparticle, highly ordered technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of pore occupancy, magnetic nanoparticle exposure, etc., and achieve efficient separation and preparation steps Simple, exposure-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

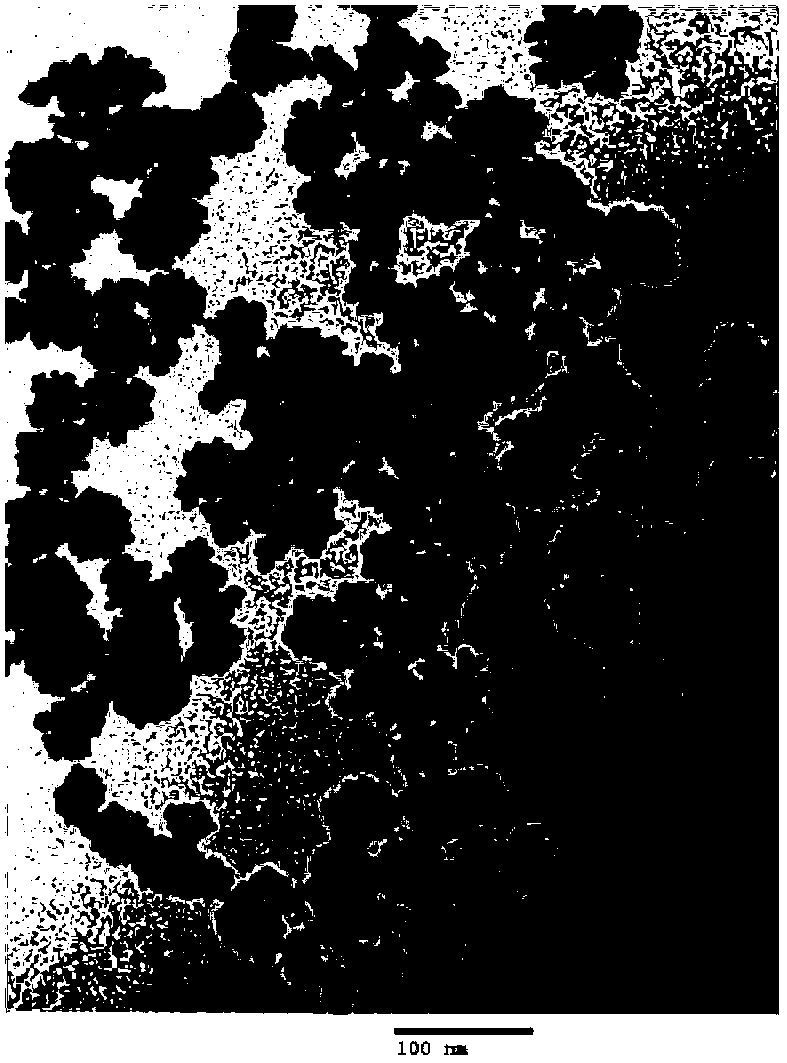

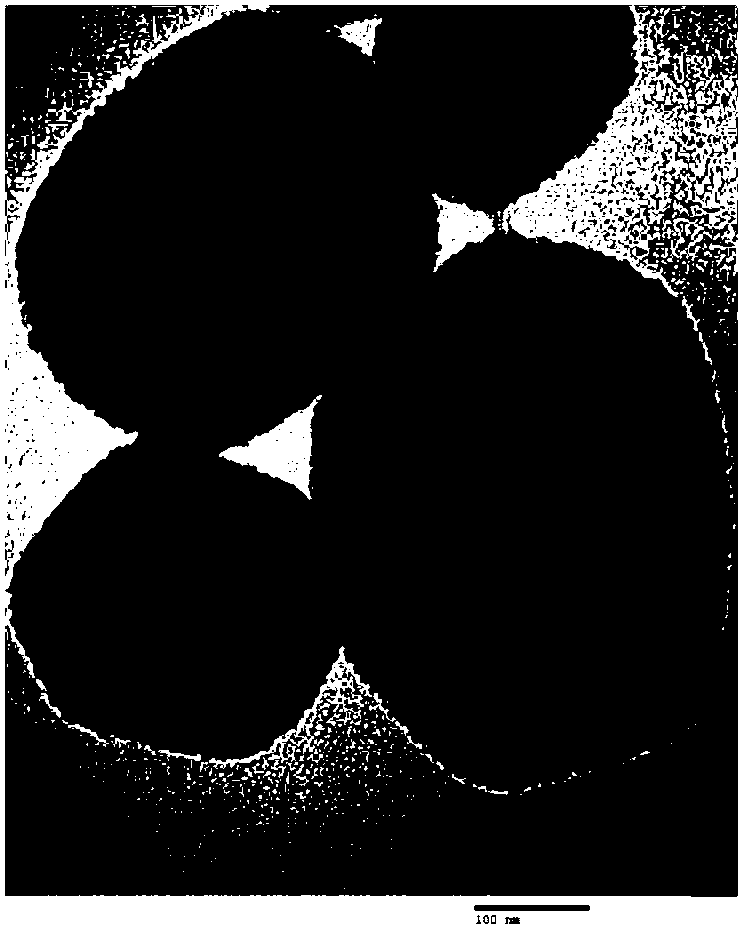

Image

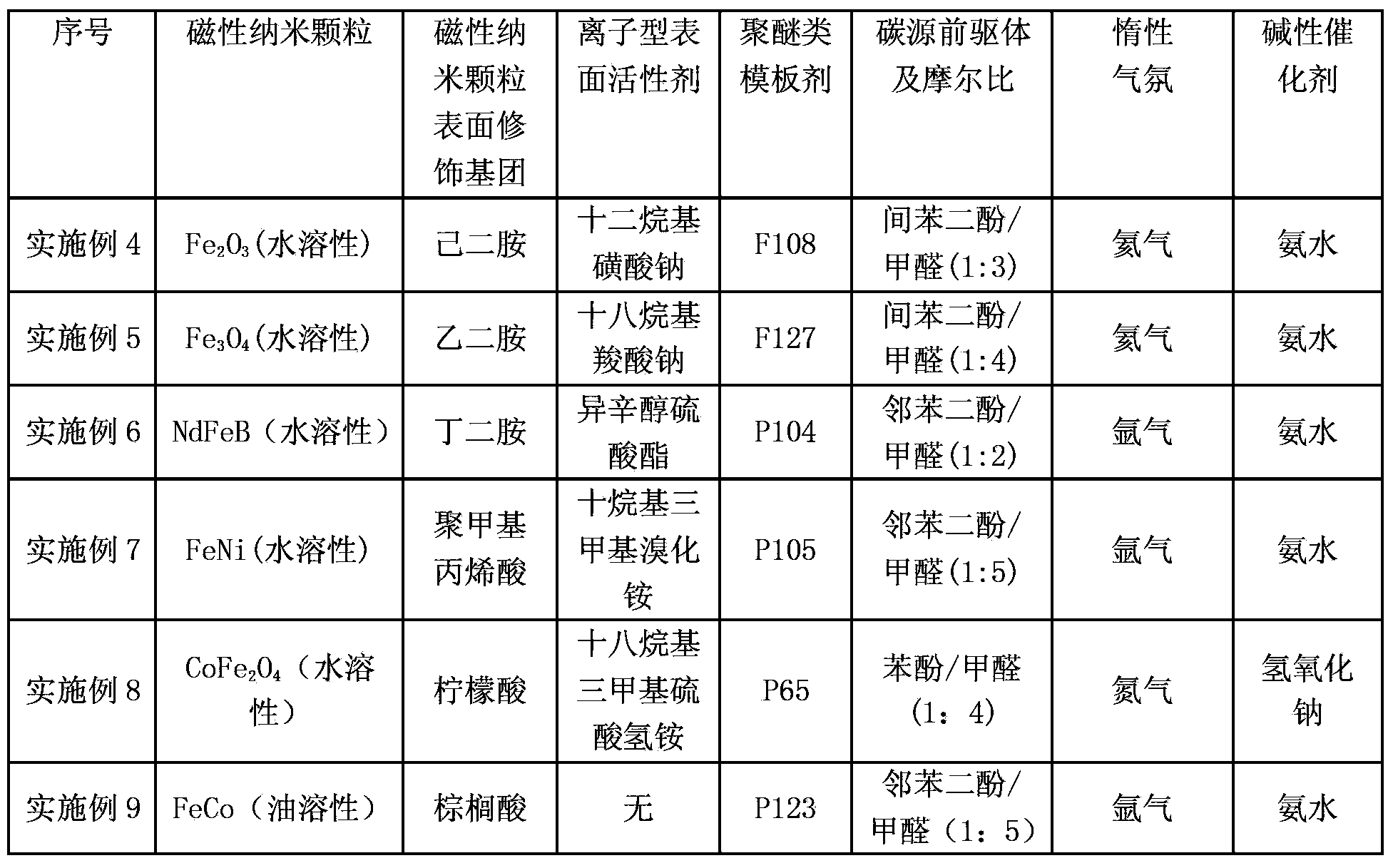

Examples

Embodiment 1

[0034] (1) Preparation of iron ferric oxide nanoparticles with polyacrylic acid on the surface: dissolve ferric chloride, sodium acetate, and sodium acrylate with a molar ratio of 1:10:10 in a mixed solvent of ethylene glycol and diethylene glycol , transferred to a hydrothermal reaction kettle after stirring, and hydrothermally reacted for 12 hours to obtain ferroferric oxide magnetic nanoparticles;

[0035] (2) Disperse ferroferric oxide magnetic nanoparticles in deionized water, add cetyltrimethylammonium bromide (CTAB), the mass ratio of ferroferric oxide magnetic nanoparticles to CTAB is 3:7, stir After a certain period of time, add polyether F127 (PEO 106 PPOs 70 PEOs 106 ), the mass ratio of F127 and ferroferrogen tetroxide magnetic nanoparticles is 5, and the ferroferrogen tetroxide magnetic nanoparticle solution whose surface is coated with CTAB surface active organic template agent is obtained by stirring;

[0036] (3) Preparation of carbon source prepolymer: phen...

Embodiment 2

[0040] (1) Preparation of iron ferric oxide nanoparticles with oleic acid on the surface: iron triacetylacetonate, ethylene glycol, oleic acid, and oleylamine are mixed in a certain proportion, and after dissolving, transfer to a hydrothermal reaction kettle and heat up to 200 ℃, hydrothermal reaction for 3 hours, and ferroferric oxide magnetic nanoparticles were prepared;

[0041] (2) Get the above-mentioned iron ferric oxide nanoparticles and disperse them in chloroform, add F127 aqueous solution, stir for a certain period of time, heat up and volatilize to remove chloroform, and obtain the iron ferric oxide nano particle solution of surface-coated surfactant;

[0042] (3) Preparation of carbon source precursor: phenol and formaldehyde are used as raw materials, and NaOH is used as a catalyst. The molar ratio of phenol and formaldehyde is 1:3. React at 70°C for 30 minutes to obtain a carbon source precursor solution.

[0043] (4) Mix the iron ferric oxide nanoparticle solut...

Embodiment 3

[0046] (1) Preparation of iron ferric oxide nanoparticles modified with octylamine on the surface: iron triacetylacetonate was added to a mixed solvent of octylamine and alcohol, transferred to a hydrothermal reaction kettle, heated to 240°C, and hydrothermally reacted for 2 hours to prepare Obtain ferroferric oxide magnetic nanoparticles;

[0047] (2) Get the above-mentioned iron ferric oxide nanoparticles and disperse them in chloroform, add F127 aqueous solution, stir for a certain period of time, heat up and volatilize to remove chloroform, and obtain the iron ferric oxide nano particle solution of surface-coated surfactant;

[0048] (3) Preparation of carbon source precursor: Resorcinol and formaldehyde are used as raw materials, and ammonia water is used as a catalyst. The molar ratio of resorcinol and formaldehyde is 1:2. React at 35°C for 30 minutes to obtain a carbon source precursor solution.

[0049] (4) Mix the iron ferric oxide nanoparticle solution and the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com