Manufacturing method for quartz comb teeth capacitive accelerometer

An accelerometer and comb-tooth capacitance technology, which is applied in the field of microelectronic machinery and sensing technology, can solve the problems that quartz materials are difficult to obtain a comb-tooth structure with a large aspect ratio, small sensor range, and large sensitive capacitance. Effects of processing yield and mechanical stability, improving sensitivity and resolution, and improving temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below just in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

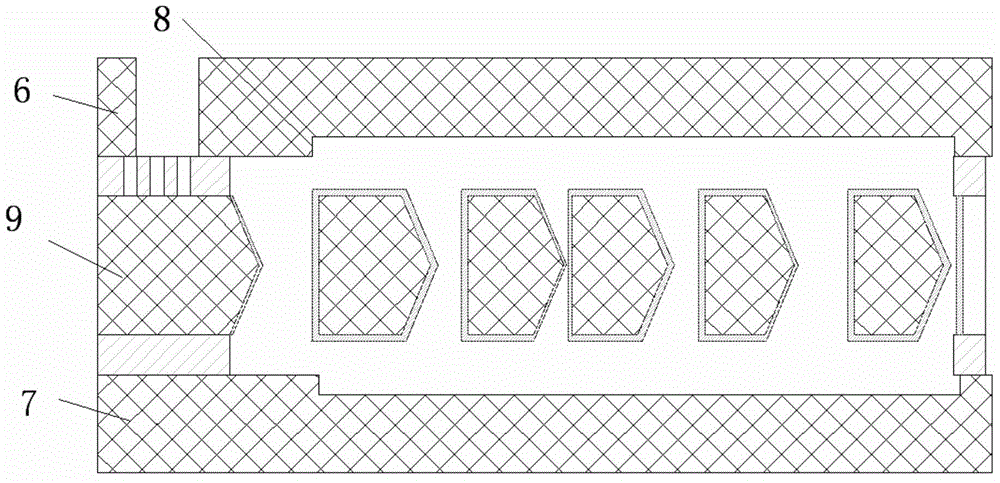

[0042] Such as figure 1 Shown is the structural representation of the quartz comb capacitive accelerometer of the present invention; figure 2 Shown is the cross-sectional view of the structure of the quartz comb capacitive accelerometer of the present invention; image 3 Shown is the schematic diagram of the sensitive part layer of the quartz comb capacitive accelerometer of the present invention, as can be seen from the figure, the accelerometer of the present invention includes an upper cover plate 6, a lower cover plate 7 and a sensitive part 9, wherein the sensitive part 9 includes a support frame 1, a sensitive mass Block 2, sensitive electrode pair 3, cantilever beam 4, stopper block 5, wherein grooves 8 are opened on the upper cover plate 6 and the lower cover plate 7, and the supporting frame 1 is located between the upper cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com