Crucible with impurity removal function and polysilicon purification or ingot method used in polysilicon purification or ingot casting

A polysilicon and ingot casting technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of reduced utilization rate, increased production and operation costs, and difficult realization of equipment transformation, and achieves strong applicability , cost reduction, easy method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

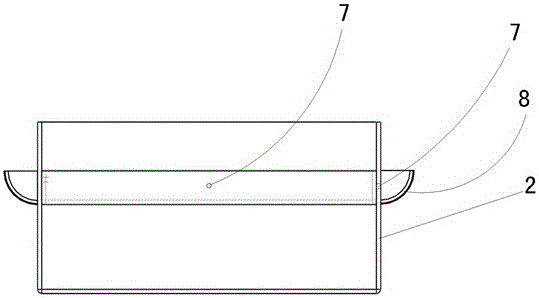

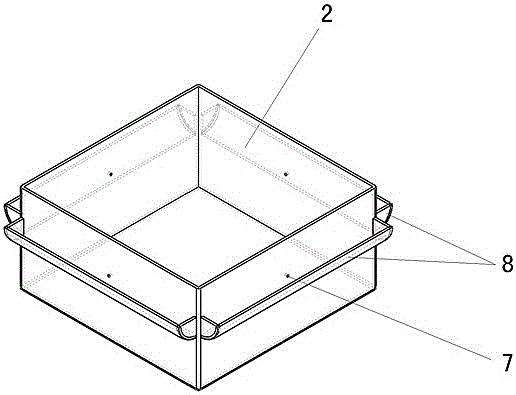

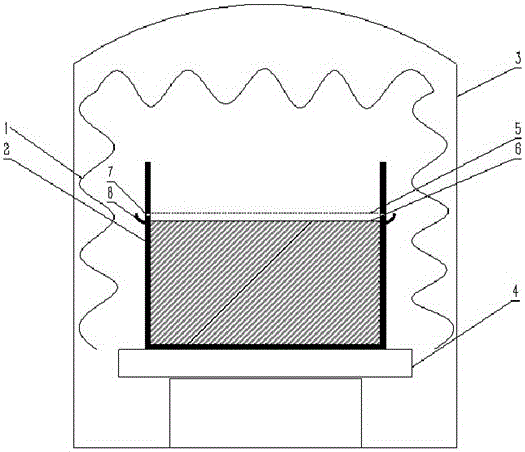

[0041] Such as figure 1 , 2 , 3: Take GT DSS450 as an example, the ingot weight is 450Kg, and the crucible size is 840mm×840mm×420mm; ρ 液 =2.42g / cm 3 , ρ 固 =2.33 g / cm 3 .

[0042] The liquid level height H of polysilicon in liquid state in the crucible 液 =V 液 / S 底 =M / ρ 液 / S 底 =263mm

[0043] After the polysilicon is crystallized in the crucible, it is cast to a certain height H 固 =V 固 / S 底 =M / ρ 固 / S 底 =273mm

[0044] The height H=H of the bottom edge of the overflow hole 7 from the inside of the crucible 2 液 +(H 固 -H 液 ) 20%, that is, the bottom edge of the overflow hole 7 is 265 mm from the inner bottom surface of the crucible 2 . When the silicon material is completely melted, the liquid level reaches 263mm, and when the bottom begins to grow oriented crystals, the liquid level will gradually rise. When reaching the drilling position of 265mm, the silicon liquid flows into the collection tank 8 through the overflow hole 7. The height of the overflow hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com