Seawater corrosion-resistant steel pipe and manufacturing method

A manufacturing method and seawater-resistant technology, applied in the field of corrosion-resistant steel pipes and their manufacture, can solve problems such as the inability to meet the yield strength of steel structures, low C content in steel materials, and increased production and manufacturing costs, and achieve good economic and market benefits. The effect of low addition amount and economical production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

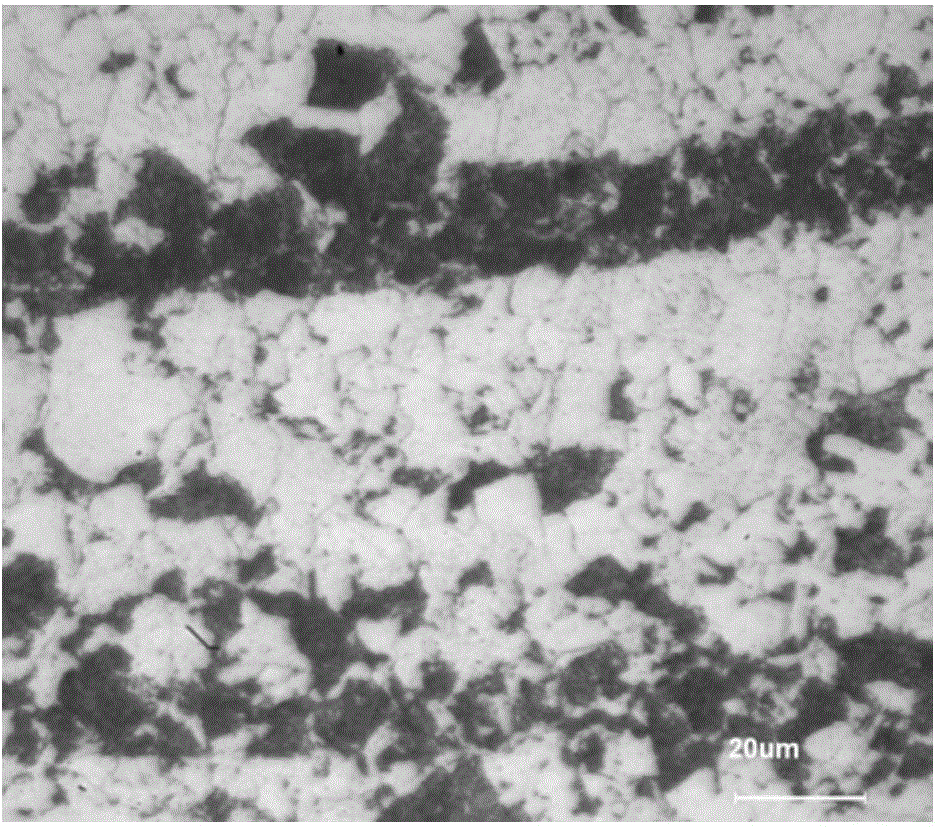

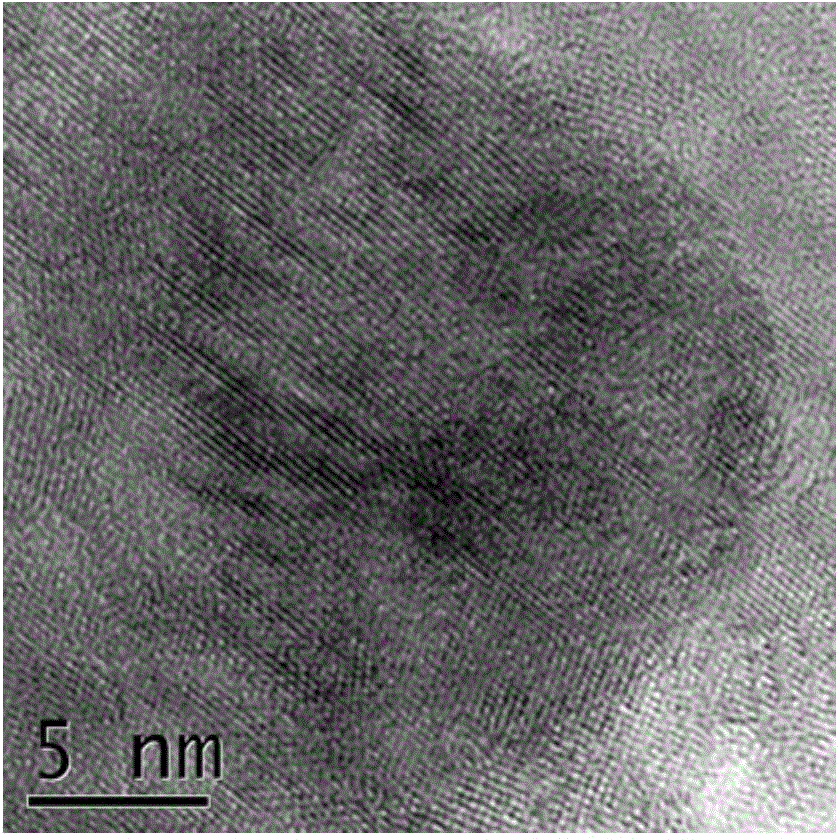

Image

Examples

Embodiment A1-A5 and comparative example B1-B2

[0056] The steel pipes in Examples A1-A5 and B1-B2 were manufactured according to the following steps:

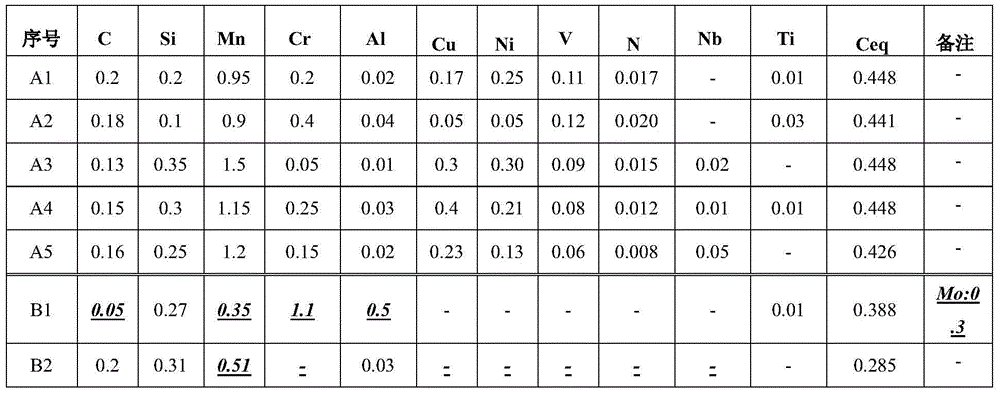

[0057] (1) Smelting: after refining outside the furnace and vacuum degassing, the mass percentage distribution ratio of each chemical element in Examples A1-A5 and B1-B2 is shown in Table 1;

[0058] (2) Continuous casting into a round billet or casting into a square billet, and rolling into a round tube billet after casting;

[0059] (3) Heating and soaking: heating to AC3 and above to keep warm and soak;

[0060] (4) Steel pipes are rolled in the austenite phase zone, and the final rolling temperature is greater than 880°C;

[0061] (5) Cool to room temperature to obtain a hot-rolled product.

[0062] It can also continue to normalize, and the normalizing temperature is 860-940°C to obtain a normalized product.

[0063] Table 1 lists the mass percentage distribution of each chemical element in the steel pipes in Examples A1-A5 and Comparative Examples B1-B2 of this cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com