A kind of industrialized production method of migration-resistant bright red pigment 150 for pu

A production method and migration-resistant technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as poor heat resistance, troubles of downstream enterprises, migration, etc., to achieve high heat resistance and ensure beating effect. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

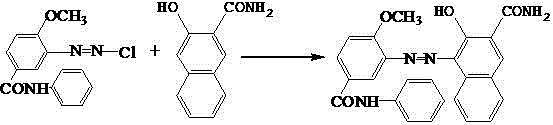

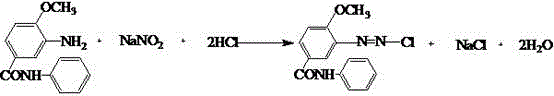

Method used

Image

Examples

Embodiment 1

[0031] 1) Put 200Kg of 3-amino-4-methoxybenzanilide into an ordinary reaction kettle, add 2000Kg of water, stir rapidly for 30 minutes, quickly add 250Kg of hydrochloric acid with a content of 30% for acid precipitation and salt formation, and obtain a dispersion liquid, and then At 0°C, add 140Kg of 30% sodium nitrite solution within 5 minutes for diazotization and stirring reaction for 1 hour. Add 240kg of industrial sodium acetate and MOA-44kg directly into the diazonium solution and stir for 10 minutes, that is, the preparation of the diazo solution is completed. , put it into the coupling reaction kettle, add 2000kg of water in the coupling reaction kettle to adjust the reaction liquid volume, and wait for the coupling reaction;

[0032] 2) Add 1600kg of water and 160kg of 30% liquid caustic soda to an ordinary reactor, start stirring, heat up to 80°C with steam, add 160kg of 2-hydroxy-3-naphthylcarboxamide until stirred and dissolved; then quickly add ice and cool down to...

Embodiment 2

[0035] 1) Put 200Kg of 3-amino-4-methoxybenzanilide into an ordinary reaction kettle, add 2000Kg of water, stir rapidly for 30 minutes, quickly add 250Kg of hydrochloric acid with a content of 30% for acid precipitation and salt formation, and obtain a dispersion liquid, and then At 0°C, add 140Kg of 30% sodium nitrite solution within 5 minutes for diazotization and stirring reaction for 1 hour. Add 240kg of industrial sodium acetate and OS-154kg directly into the diazonium solution and stir for 10 minutes, that is, the preparation of the diazo solution is completed. , put it into the coupling reaction kettle, add 2000kg of water in the coupling reaction kettle to adjust the reaction liquid volume, and wait for the coupling reaction;

[0036] 2) Add 1600kg of water and 160kg of 30% liquid caustic soda to an ordinary reactor, start stirring, heat up to 80°C with steam, add 160kg of 2-hydroxy-3-naphthylcarboxamide until stirred and dissolved; then quickly add ice and cool down to...

Embodiment 3

[0039] 1) Put 200Kg of 3-amino-4-methoxybenzanilide into an ordinary reaction kettle, add 2000Kg of water, stir rapidly for 30 minutes, quickly add 320Kg of hydrochloric acid with a content of 30% for acid precipitation and salt formation, and obtain a dispersion liquid, and then At 0°C, add 140Kg of 30% sodium nitrite solution within 5 minutes for diazotization and stirring reaction for 1 hour. Add 240kg of industrial sodium acetate and MOA-46kg directly into the diazonium solution and stir for 10 minutes, that is, the preparation of the diazo solution is completed. , put it into the coupling reaction kettle, add 2000kg of water in the coupling reaction kettle to adjust the reaction liquid volume, and wait for the coupling reaction

[0040] 2) Add 1600kg of water and 160kg of 30% liquid caustic soda to an ordinary reactor, start stirring, and heat up to 82°C with steam, then add 8kg of 3-hydroxy-2-naphthoic acid and 152kg of 2-hydroxy-3-naphthoamide until stirring and dissolving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com