A process for producing sintered bricks with ultra-high content of fly ash

A technology for fly ash and sintered bricks, which is applied in the technological field of producing sintered bricks with ultra-high content of fly ash, can solve the problems of product strength influence, large drying shrinkage, easy deformation of wet blanks, etc. risk, solve corrosion resistance problems, improve the effectiveness of dry contact surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

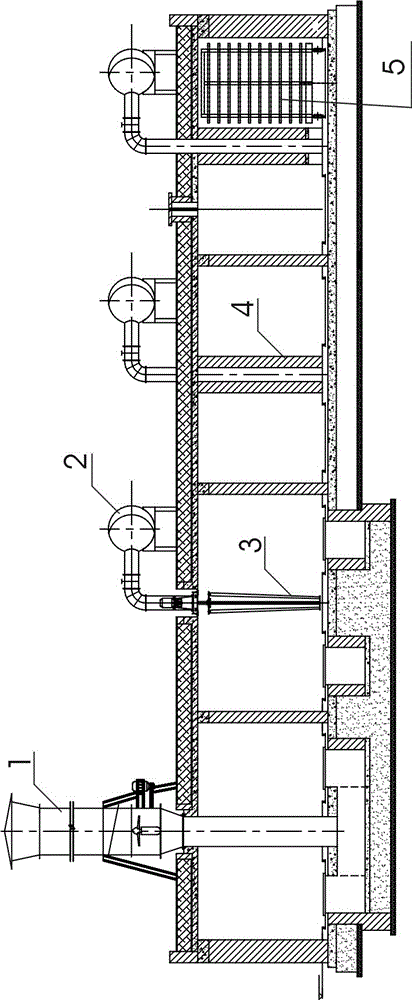

Image

Examples

Embodiment 1

[0025] Prepare materials by weight:

[0026] Material name parts by weight

[0027] 62 parts of fly ash

[0028] Hard Shale 38 parts

[0029] The hard shale is sent to the hammer crusher for crushing, and then sent to the pendulum mill for further refining treatment. The particle size of the shale powder after refining treatment is below 2mm, and the particles below 1mm account for 82wt% , Particles below 0.25mm accounted for 35wt%. Feed the fly ash and finely ground shale powder into the rod mixer for mixing; after mixing evenly, send them into the first double-shaft mixer, add room temperature water for stirring; after stirring evenly , into the second twin-shaft mixer, based on the total weight of the fly ash and the refined shale powder, add 15wt% of 90-degree hot water for stirring.

[0030] Afterwards, the stirred material is sent to the aging warehouse for aging for more than 72 hours. The aged material is extruded through a two-stage vacuum brick extrusion machine...

Embodiment 2

[0034] Prepare materials by weight:

[0035] Material name parts by weight

[0036] 65 parts of fly ash

[0037] Hard Shale 35 parts

[0038] The hard shale is sent to the hammer crusher for crushing, and then sent to the pendulum mill for further refinement. The particle size of the shale powder after refinement is below 1.8mm, and the particles below 1.5mm account for 85wt%, particles below 0.25mm accounted for 40wt%. Send the fly ash and ground shale powder into the rod mixer for mixing; after mixing evenly, send them into the first double-shaft mixer, add room temperature water for stirring; after stirring evenly, send them into In the second twin-shaft mixer, based on the total weight of the fly ash and the refined shale powder, 18% of water or steam is added for stirring.

[0039] Afterwards, the stirred material is sent to the aging warehouse for aging for more than 72 hours. The aged material is extruded through a two-stage vacuum brick extrusion machine, the extr...

Embodiment 3

[0043] Prepare materials by weight:

[0044] Material name parts by weight

[0045] 70 parts of fly ash

[0046] 30 parts of clay

[0047] The rest of the production process is the same as in Example 1, the difference is only that the clay is crushed by using a high-speed finely crushed pair of rollers, and the firing temperature is set at 1080°C

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com