Method for drying honeycomb type denitrated ceramic catalyst

A technology of ceramic catalyst and drying method, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of long drying time, large energy consumption in drying process, small processing capacity, etc., and achieve high product quality and drying ability. Strong and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

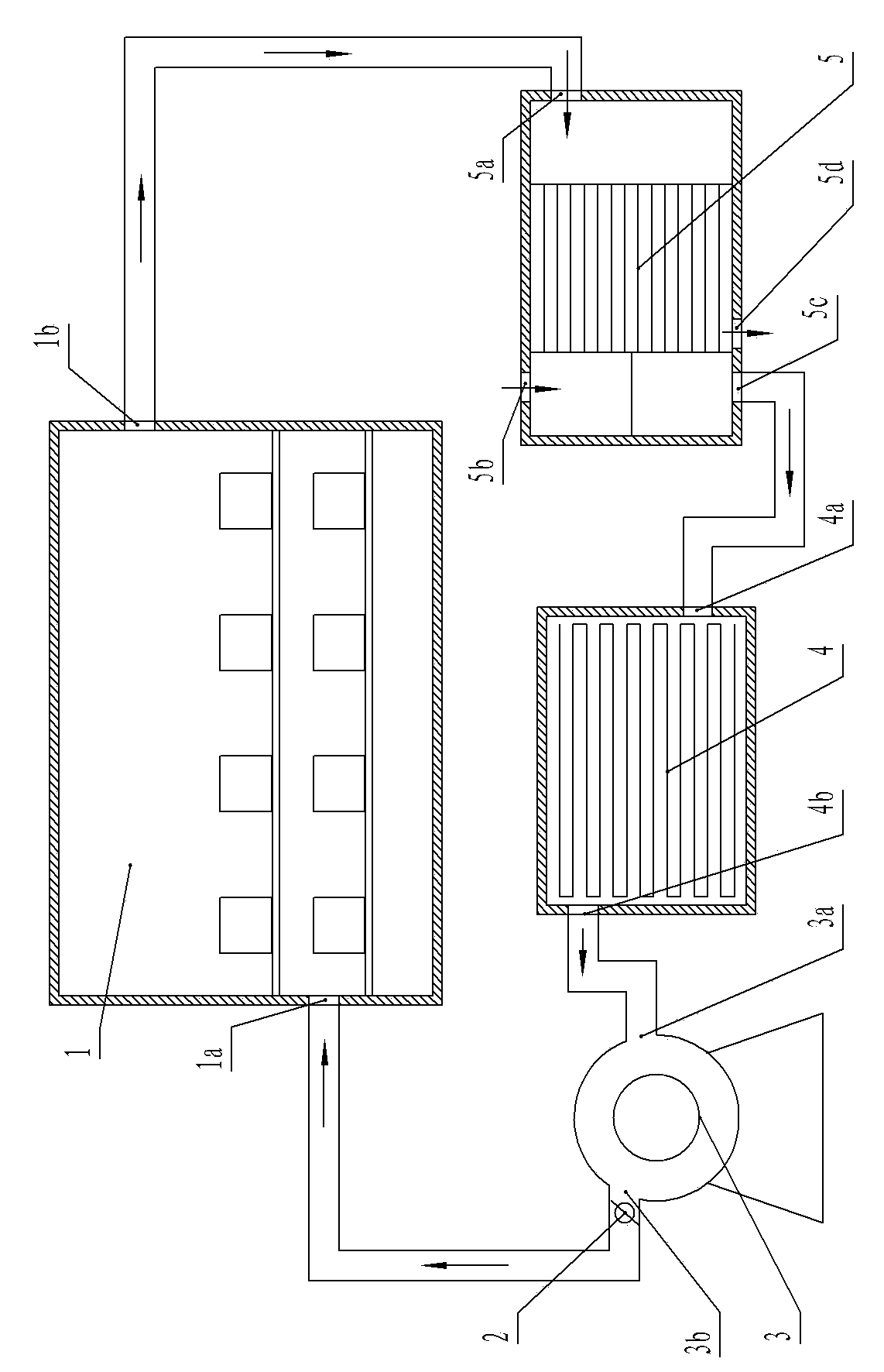

Image

Examples

Embodiment 1

[0021] Its drying process is as follows:

[0022] First drying process:

[0023] a. Place the prepared honeycomb denitration ceramic catalyst shaped body in a drying chamber;

[0024] b. Through the blower, the air volume is 4000m 3 / h, send hot air into the drying room from the air inlet of the drying room, keep the indoor temperature at 50°C, and the humidity at 65%, for 4 days;

[0025] During this process, the free water in the honeycomb body of the honeycomb denitrification ceramic catalyst is squeezed out and gradually taken away;

[0026] Second drying process:

[0027] a. The honeycomb type denitration ceramic catalyst honeycomb body obtained in the first drying process is placed in a drying box,

[0028] b. Send hot air from the air inlet of the drying box into the drying box by a blower, and keep the temperature in the box at 100°C until the moisture content of the honeycomb denitration ceramic catalyst is 2%.

[0029] During this process, when the hot air passe...

Embodiment 2

[0031] Its drying process is as follows:

[0032] First drying process:

[0033] a. Place the prepared honeycomb denitration ceramic catalyst shaped body in a drying chamber;

[0034] b. Through the blower, the air volume is 4000m 3 / h, send hot air into the drying room from the air inlet of the drying room, keep the indoor temperature at 55°C, and the humidity at 60%, for 4 days;

[0035] During this process, the free water in the honeycomb body of the honeycomb denitrification ceramic catalyst is squeezed out and gradually taken away;

[0036] Second drying process:

[0037] a. The honeycomb type denitration ceramic catalyst honeycomb body obtained in the first drying process is placed in a drying box,

[0038] b. Send hot air from the air inlet of the drying box into the drying box by a blower, and keep the temperature in the box at 105°C until the moisture content of the honeycomb denitration ceramic catalyst is 1.8%.

[0039] During this process, when the hot air pas...

Embodiment 3

[0041] Its drying process is as follows:

[0042] First drying process:

[0043] a. Place the prepared honeycomb denitration ceramic catalyst shaped body in a drying chamber;

[0044] b. Through the blower, the air volume is 4000m 3 / h, send hot air into the drying room from the air inlet of the drying room, keep the indoor temperature at 60°C, and the humidity at 55%, for 4 days;

[0045] During this process, the free water in the honeycomb body of the honeycomb denitrification ceramic catalyst is squeezed out and gradually taken away;

[0046] Second drying process:

[0047] a. The honeycomb type denitration ceramic catalyst honeycomb body obtained in the first drying process is placed in a drying box,

[0048] b. Send hot air from the air inlet of the drying box into the drying box by a blower, and keep the temperature in the box at 110°C until the moisture content of the honeycomb denitration ceramic catalyst is 1.5%.

[0049] During this process, when the hot air pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com