Anaerobic adhesive for screw thread locking or pipe thread sealing

A pipe thread and anaerobic adhesive technology, applied in the field of anaerobic adhesives, can solve problems such as unsatisfactory effects and high toxicity, and achieve the effects of reducing the chance of backflow into the food field, low toxicity, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

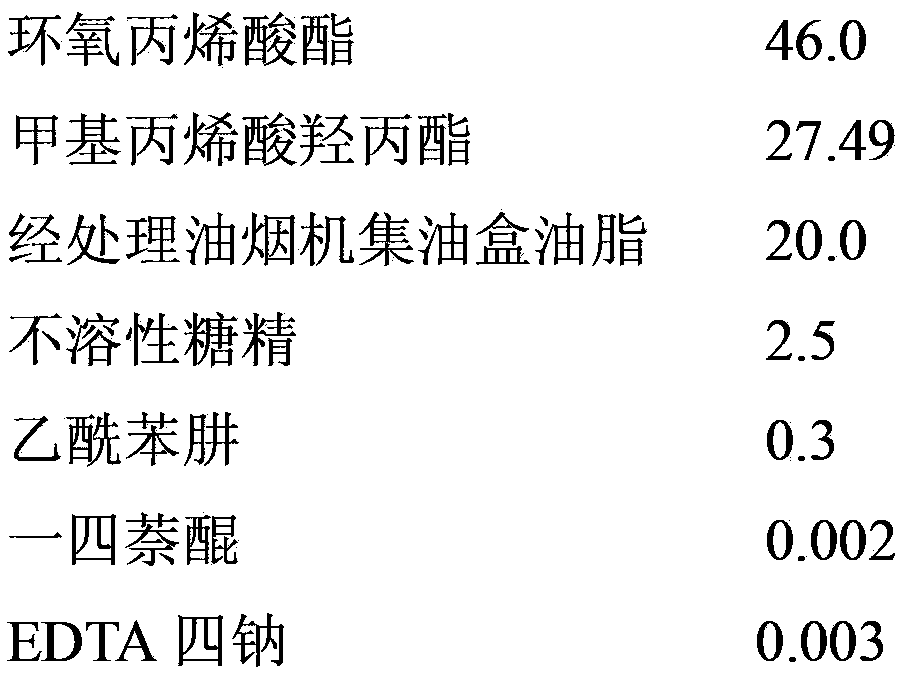

[0025] Weigh each component of the following parts by weight:

[0026]

[0027]

[0028] The above combinations are mixed evenly to obtain the anaerobic adhesive of the present invention.

[0029] In the present embodiment, the treated grease from the oil collection box of the range hood is used as a plasticizer, insoluble saccharin is used as an accelerator, acetylphenylhydrazine, tetranaphthoquinone, tetrasodium EDTA, and hydroxyethylidene diphosphonic acid are used as a stabilizer, and isopropylidene diphosphonic acid is used as a stabilizer. Benzene hydroperoxide was used as an initiator and fumed silica as a viscosity modifier. The anaerobic adhesive prepared in this example is mainly used for thread locking.

[0030] Stable storage: Add the anaerobic adhesive prepared in Example 1 into a 10*75mm glass test tube, and measure its hardening time in the test tube in a constant temperature water bath at 82°C. The general anaerobic adhesive standard is >2 hours, and the...

Embodiment 2

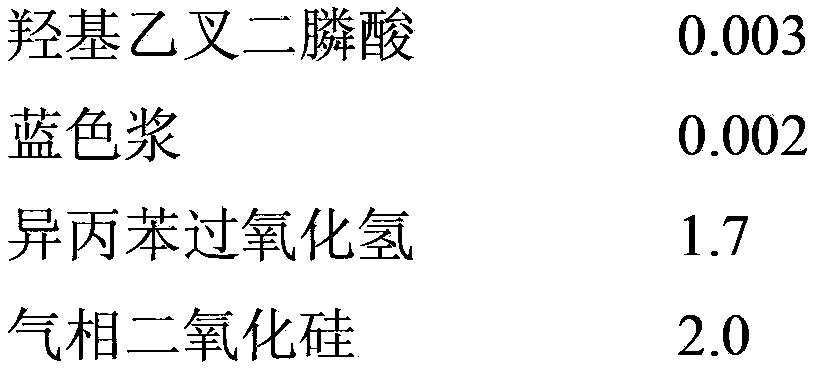

[0032] Weigh each component of the following parts by weight:

[0033]

[0034] The above combinations are mixed evenly to obtain the anaerobic adhesive of the present invention.

[0035] In the present embodiment, the treated grease from the oil collection box of the range hood is used as a plasticizer, insoluble saccharin is used as an accelerator, acetophenhydrazine, tetranaphthoquinone, and disodium EDTA are used as a stabilizer, and cumene peroxidation is used as an initiator. Fumed silica is used as a viscosity modifier, and blue paste is used as a pigment to identify various anaerobic adhesives. The anaerobic adhesive prepared in this example is mainly used for thread locking.

[0036] Stable storage: Add the anaerobic adhesive prepared in Example 2 into a 10*75mm glass test tube, and measure its hardening time in the test tube in a constant temperature water bath at 82°C. The general anaerobic adhesive standard is >2 hours, and the sample in Example 3 is hardened ...

Embodiment 3

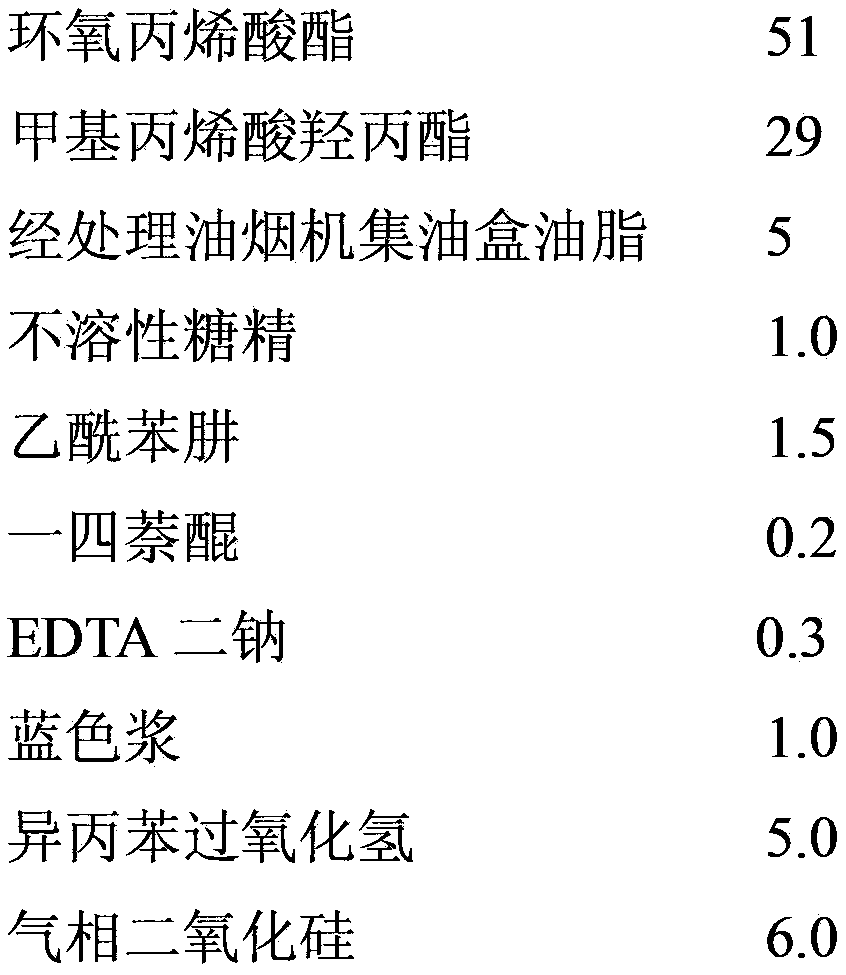

[0043] Weigh each component of the following parts by weight:

[0044]

[0045]

[0046] The above combinations are mixed evenly to obtain the anaerobic adhesive of the present invention.

[0047] In this embodiment, the treated frying oil is used as plasticizer, insoluble saccharin as accelerator, acetylphenylhydrazine, tetranaphthoquinone, tetrasodium EDTA, hydroxyethylidene diphosphonic acid as stabilizer, titanium dioxide, mica powder, polytetrafluoroethylene powder, polyethylene powder as a filler, cumene hydroperoxide as an initiator, and fumed silica as a viscosity regulator. The anaerobic adhesive prepared in this example is mainly used for thread sealing.

[0048]Stable storage: Add the anaerobic adhesive prepared in Example 3 into a 10*75mm glass test tube, and measure its hardening time in the test tube in a constant temperature water bath at 82°C. The general anaerobic adhesive standard is >2 hours, and the sample in Example 2 is hardened Time >3 hours. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com