Heat conductive composite material with high volume fraction and preparation method thereof

A heat-conducting composite material with a high volume fraction technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult dispersion of fillers, poor heat dissipation, high energy consumption, etc., and achieve excellent thermal conductivity and mechanical properties. Improved mechanical properties and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

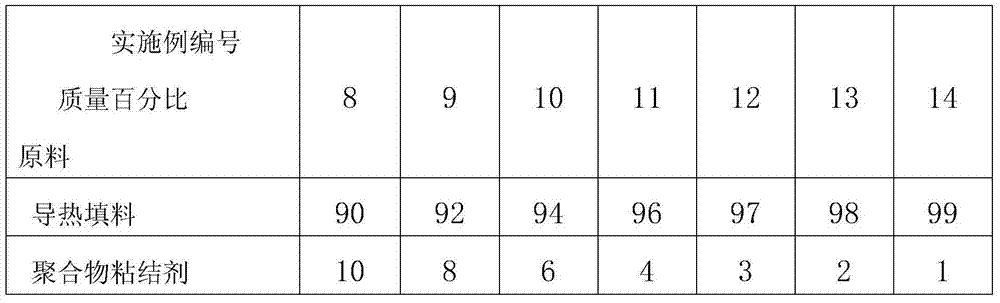

Examples

Embodiment 1

[0038] A heat-conducting composite material with a high volume fraction, which is composed of: 97wt% carbon nanotubes (single-walled carbon nanotubes or multi-walled carbon nanotubes, the same hereinafter) and 3wt% polytetrafluoroethylene.

[0039] The preparation method of the high volume fraction thermally conductive composite material, the steps are:

[0040] a. Put 97wt% of carbon-based filler and 3wt% of polytetrafluoroethylene into a blast oven, and blow dry at a temperature of 120°C for 15h;

[0041] b. Put the fully dried carbon-based filler powder and polymer binder powder into a high-speed multifunctional pulverizer, stir and mix at a high speed for 2 minutes, and the stirring rate is 25,000 rpm to obtain a fully mixed modeling powder;

[0042] c. Put the fully mixed molding powder evenly into the molding mold, and keep the mold with the molding powder at a temperature of 340°C for 2 hours; at the same time, keep the molding mold with the mixed molding powder at a pr...

Embodiment 2

[0046] The preparation process of the high volume fraction heat-conducting composite material in this example refers to Example 1. Compared with Example 1, the process parameters are basically the same, only the proportion of materials is changed. The mass percentage proportion of the high volume fraction heat-conducting composite material is: Carbon nanotube 94wt%, polytetrafluoroethylene 6wt%.

[0047] The performance test data of the obtained high volume fraction thermally conductive composite material is as follows: thermal conductivity: 13.2Wm -1 K -1 , Compressive strength: 35.68MPa, tensile strength: 10.93MPa.

Embodiment 3

[0049] The preparation process of the high volume fraction heat-conducting composite material in this example refers to Example 1. Compared with Example 1, the process parameters are basically the same, only the proportion of materials is changed. The mass percentage proportion of the high volume fraction heat-conducting composite material is: Carbon nanotube 90wt%, polytetrafluoroethylene 10wt%.

[0050] The performance test data of the obtained high volume fraction thermally conductive composite material is as follows: thermal conductivity: 10.53Wm -1 K -1 , Compressive strength: 45.38MPa, tensile strength: 12.52MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com