Composition for forming secondary cell electrode, secondary cell electrode, and secondary cell

A secondary battery and composition technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte storage battery electrodes, etc., can solve the problems of insufficient improvement of electrode flexibility, insufficient improvement of adhesion, etc., to achieve charging and discharging Excellent cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

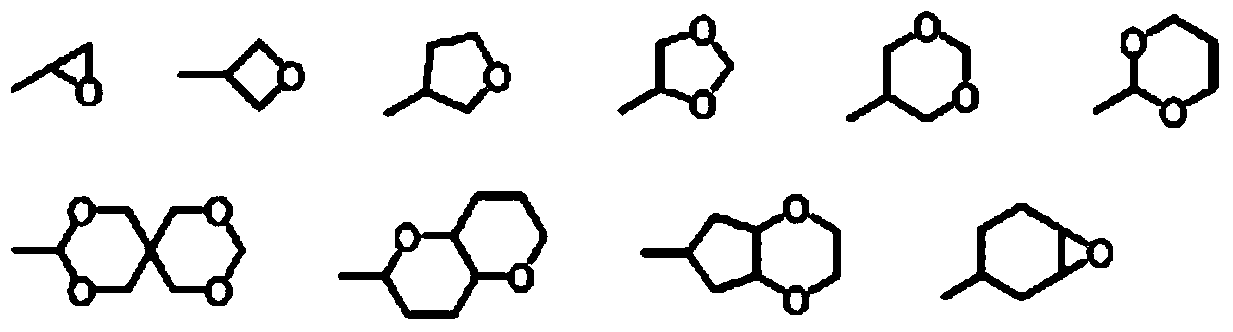

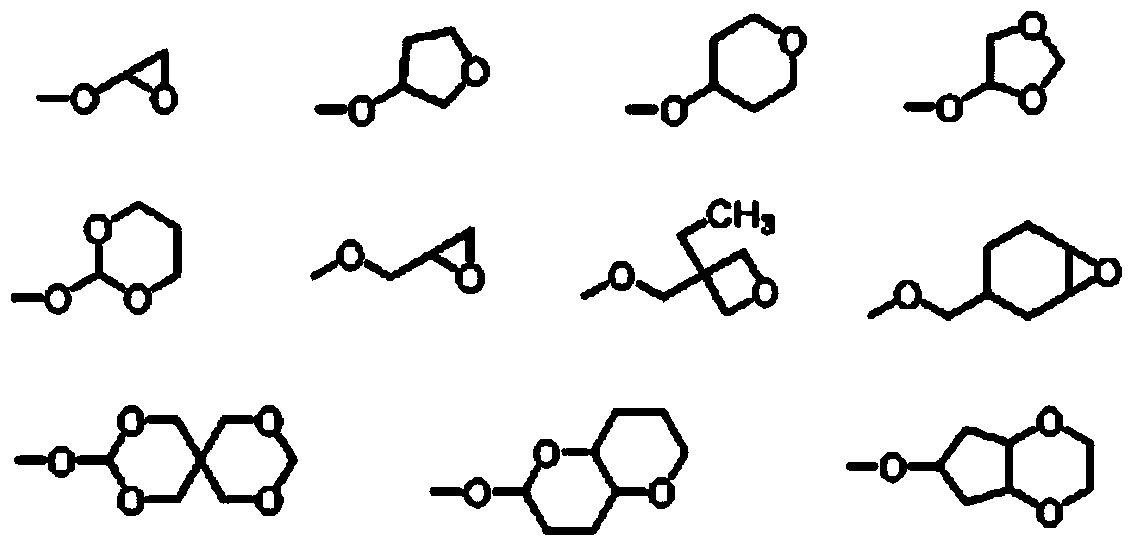

Method used

Image

Examples

Embodiment 1

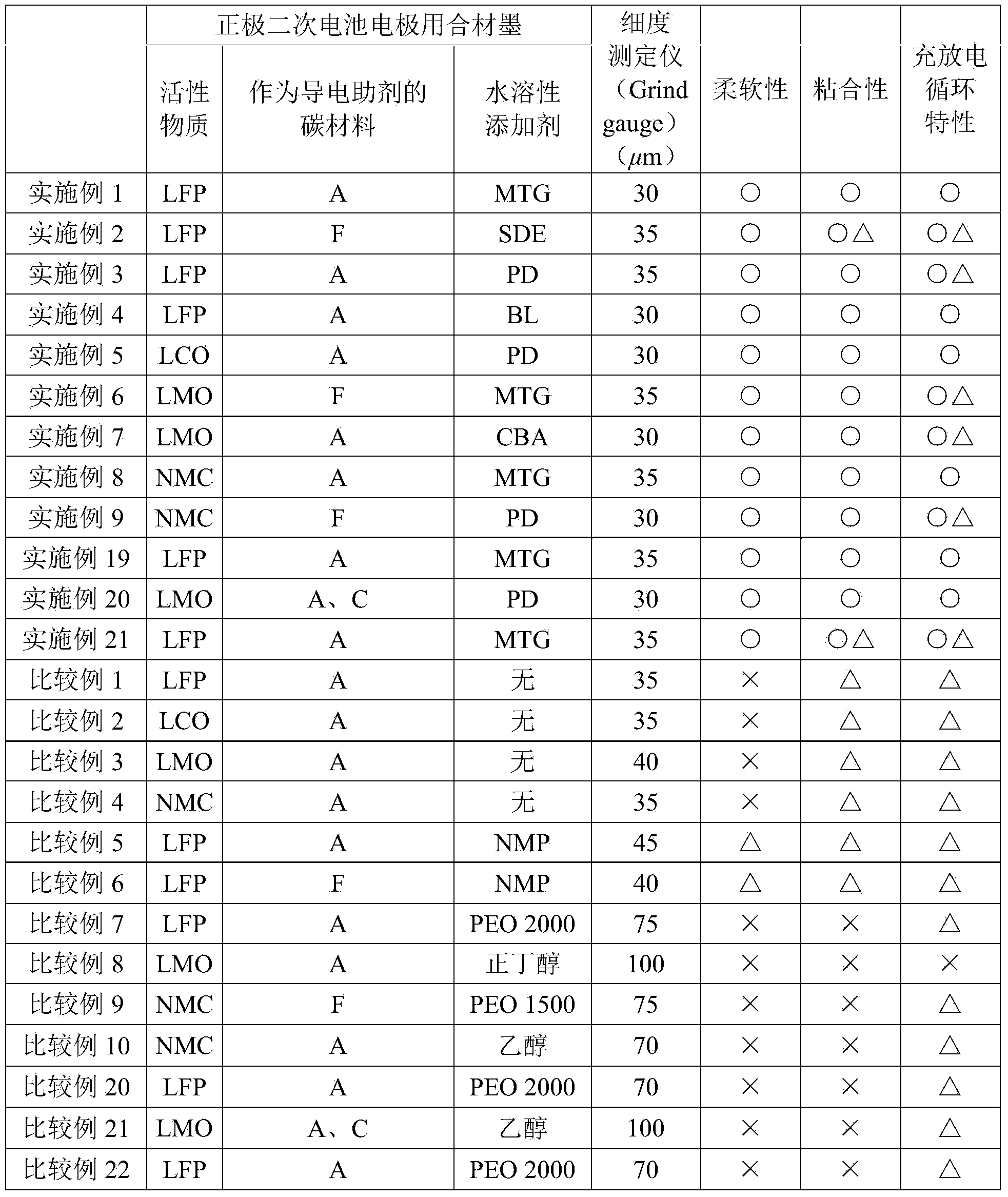

[0190] 45 parts of LiFePO as the positive active material 4 , 2.5 parts of acetylene black (Denka Black HS-100), 50 parts (1 part as solid content) of carboxymethyl cellulose 2% by weight as the carbon material of the conduction aid are put into the mixer and mixed, and further mixed into 2 parts of water-soluble additive MTG (triethylene glycol monomethyl ether), 2.5 parts of binder (polytetrafluoroethylene 30-J, 60% aqueous dispersion, manufactured by Mitsui DuPont Flowro Chemical Co., Ltd.), so that the final solid content It adjusted so that it may become about 50 weight%, and the composite material ink for positive electrode secondary battery electrodes was obtained. The degree of dispersion of the composite ink as a positive electrode secondary battery electrode was determined by the following method.

[0191] Furthermore, this composite ink for positive secondary battery electrodes was coated on an aluminum foil with a thickness of 20 μm as a current collector with a d...

Embodiment 2~9

[0194] [Examples 2-9], [Comparative Examples 1-10]

[0195] Using the active material shown in Table 1, the carbon material as a conductive additive, and the water-soluble additive, a composite ink for a positive electrode secondary battery electrode and a positive electrode were obtained by the same procedure as in Example 1, and were evaluated in the same manner. At this time, the composite ink for a positive electrode secondary battery electrode using the active material LCO, LMO, or NMC is also adjusted so that the final solid content becomes about 50% by weight.

Embodiment 19

[0197] 45 parts of LiFePO as the positive active material 4 , 2.5 parts of acetylene black (Denka Black HS-100), 50 parts (1 part as solid content) of carboxymethyl cellulose 2% by weight as the carbon material of the conduction auxiliary agent are charged into a mixer and mixed, and further mixed into 0.25 parts of water-soluble additive MTG, 2.5 parts of binder (polytetrafluoroethylene 30-J, 60% aqueous dispersion, manufactured by Mitsui Dupont Fluro Chemical Co., Ltd.), adjusted so that the final solid content reaches about 50% by weight , obtained composite ink for positive secondary battery electrode.

[0198] Furthermore, this composite ink for positive secondary battery electrodes was coated on an aluminum foil with a thickness of 20 μm as a current collector with a doctor blade, and then heated and dried under reduced pressure to adjust the thickness of the electrode to 100 μm. The flexibility of the electrodes was evaluated by the method described later.

[0199] Fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com