Surface coating method for ternary positive material of lithium ion battery

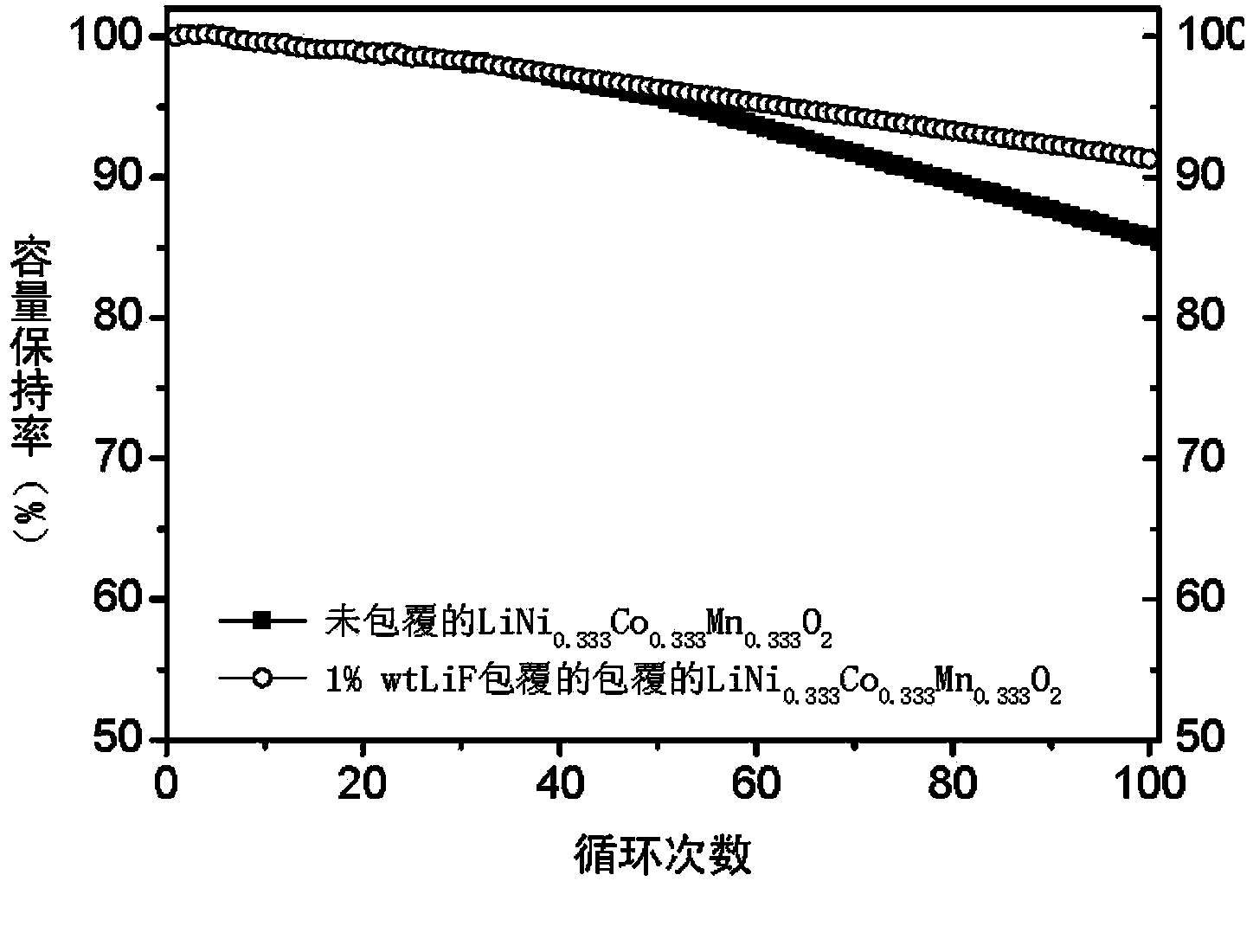

A lithium-ion battery, ternary material technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of short cycle life, poor safety, and insignificant side reaction inhibition of ternary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.1-0.5g of analytically pure lithium fluoride and add it into 100g of dimethyl sulfoxide solvent, and form a uniform solution after stirring for 5 hours. 100g of positive electrode ternary material LiNi with a size of 1-5 microns 0.333 co 0.333 mn 0.333 o 2 Put into the above solution and heat to 30 o C, 500rpm electromagnetic stirring for 30 minutes. at 60 o C and under the situation of continuing to stir, add the ethanol of 30g to above-mentioned suspension liquid, drip according to the speed of 2g / min, continue to keep temperature and stir 10 hours after dropwise addition, seal simultaneously to avoid ethanol volatilization. Stop stirring and heating, let it stand for 1 hour, skim off the supernatant, filter the precipitate with suction, and wash several times with a small amount of ethanol. transfer to 70 o Bake in a blast oven for 5 hours. into the muffle furnace, in the air according to 0.5 o C / min speed heating to 600 o C for 12 hours, and then 0...

Embodiment 2

[0031] Weigh 0.5-1 g of analytically pure lithium fluoride and add it into 100 g of dimethylformamide solvent, and stir for 2 hours to form a uniform solution. 200g of positive electrode ternary material LiNi with a particle size between 5-10 microns 0.4 co 0.2 mn 0.4 o 2 Put into the above solution and heat to 40 o C, 1000rpm electromagnetic stirring for 10 minutes. at 40 o C. In the case of continuing to stir, add 50g of ethyl acetate to the above suspension, drop it in at a rate of 5g / min, keep the temperature and stir for 5 hours after the dropwise addition, and seal it to avoid volatilization of ethyl acetate. Stop stirring and heating, let it stand for 1 hour, skim off the supernatant, filter the precipitate with suction, and wash several times with a small amount of ethyl acetate. transfer to 70 o Bake in a blast oven for 5 hours. Transfer to the muffle furnace, in the air according to 1 o C / min speed heating to 450 o C for 24 hours, and then 1 o C / min speed ...

Embodiment 3

[0033] Weigh 1-2 g of analytically pure sodium fluoride and lithium oxide mixture according to the stoichiometric ratio, add it to 100 g of diethylformamide solvent, and start stirring. With the help of a small amount of water in the air, lithium oxide was dissolved into lithium hydroxide, and a homogeneous solution was formed after stirring for 10 hours. 200g of positive electrode ternary material LiNi with a size of 0.5-1 micron 0.5 co 0.2 mn 0.3 o 2 Put into the above solution and heat to 50 o C, 1000rpm electromagnetic stirring for 10 minutes. at 50 o C, in the case of continuing to stir, add 70g of ethanol, propanol, isopropanol equal-volume mixed solution to the above suspension, drop in according to the speed of 5g / min, continue to keep the temperature and stir for 5 hours after the dropwise addition is completed, At the same time, it is sealed to prevent the volatilization of volume mixtures such as methanol and ethanol. Stop stirring and heating, let it stand f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com