A light-emitting diode with an anti-expansion layer and its manufacturing method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of epitaxial layer, oxide layer shedding, and poor connection, so as to avoid epitaxial layer shedding, structural connection stability, and improve external quantum luminescence efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

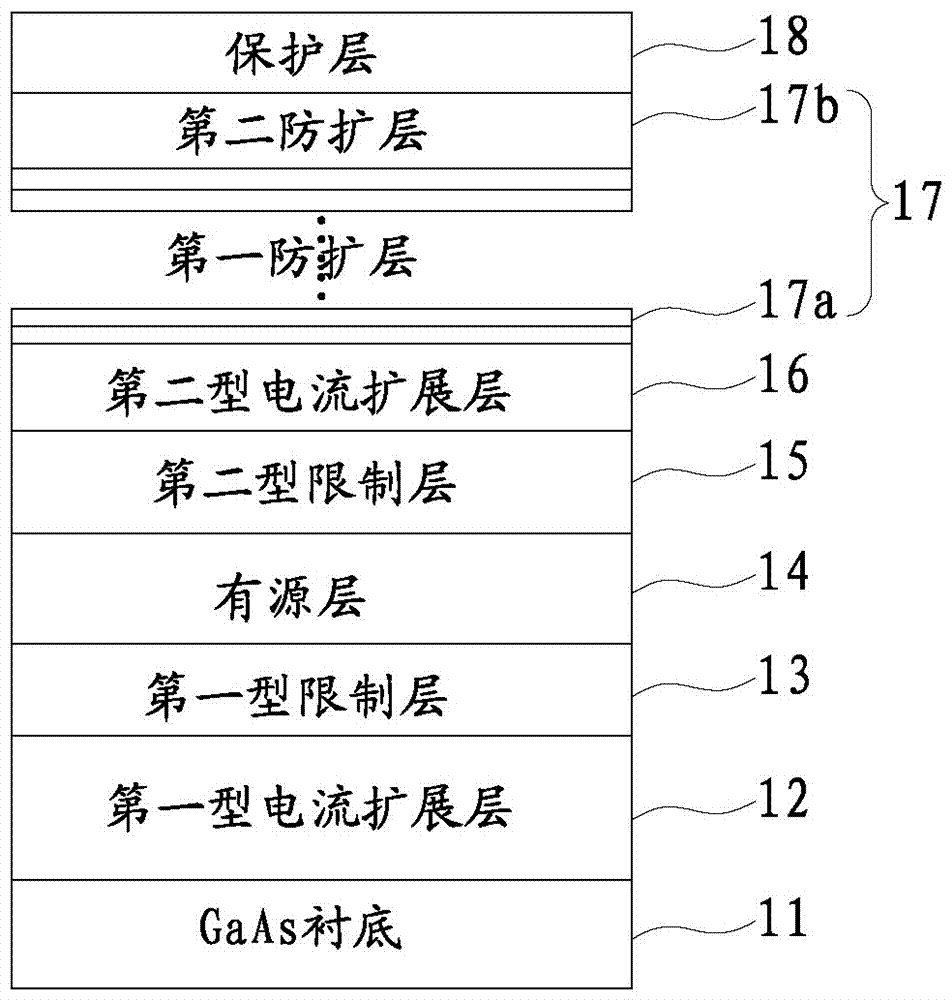

[0055] figure 1 As shown, the epitaxial structure of a light-emitting diode with an inverted structure disclosed in the present invention includes a GaAs substrate 11, and a first-type current spreading layer 12, a first-type confinement layer 13, and a Source layer 14, second-type confinement layer 15, second-type current spreading layer 16, anti-spreading layer 17, and protective layer 18, wherein the anti-spreading layer 17 is epitaxially formed by the first anti-spreading layer 17a and the second anti-spreading layer 17b Structure and composition.

[0056] Consists of a first-type current spreading layer 12 (N-type current spreading layer), a first-type confinement layer 13 (N-type confinement layer), an active layer 14, a second-type confinement layer 15 (P-type confinement layer), a second-type confinement layer The material of the current spreading layer 16 (P-type current spreading layer) is a group III-V compound such as AlGaInP. Specifically, the first-type current...

Embodiment 2

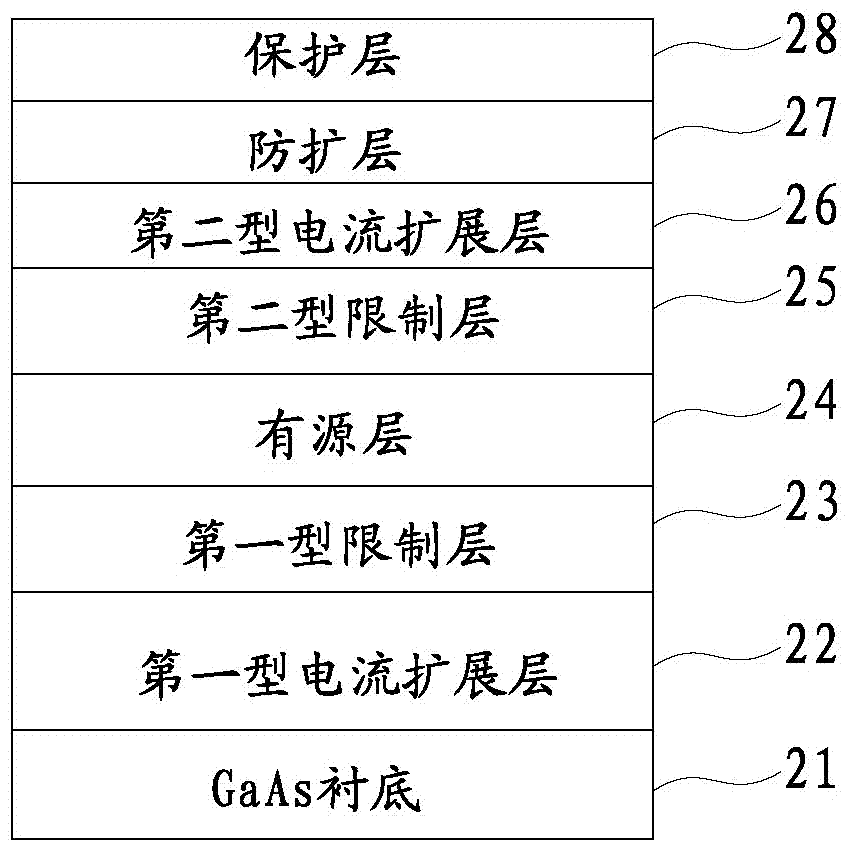

[0070] image 3 As shown, the epitaxial structure of an inverted light-emitting diode disclosed in the present invention includes a GaAs substrate 21, and along the upper surface of the GaAs substrate 21, a first-type current spreading layer 22, a second-type confinement layer 23, The active layer 24 , the second-type confinement layer 25 , the second-type current spreading layer 26 , the anti-spreading layer 27 and the protection layer 28 .

[0071] Consists of a first-type current spreading layer 22 (N-type current spreading layer), a first-type confinement layer 23 (N-type confinement layer), an active layer 24, a second-type confinement layer 25 (P-type confinement layer), a second-type confinement layer The material of the current spreading layer 26 (P-type current spreading layer) is a group III-V compound such as AlGaInP. Specifically, the first type current spreading layer 22 is made of (Al 0.35 Ga 0.65 ) 0.5 In 0.5 Composed of P material, the first-type confineme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com