X-ray fluorescent spectrum fundamental parameter method utilizing virtually synthesized standard sample

A basic parameter, fluorescence spectrum technology, applied in the field of X-ray fluorescence spectrum detection, to achieve the effect of solving different problems of different cross-section components and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

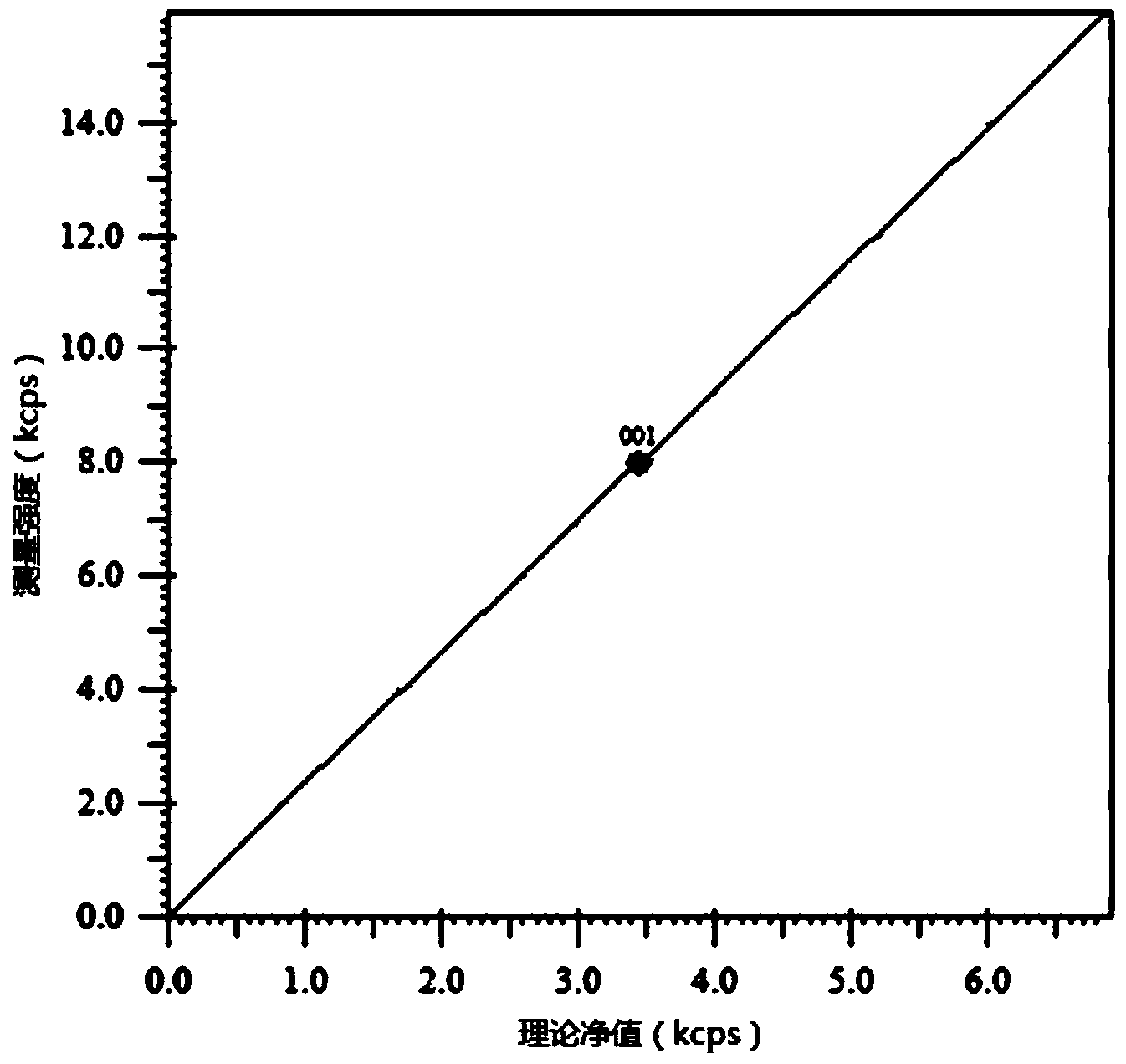

Image

Examples

Embodiment 1

[0026] Application of Iron-Based Alloys

[0027] Step 1: This embodiment selects the following standard samples:

[0028] (1) 1Cr18Ni9Ti, 7 pieces, this sleeve is used as the main sleeve, except for the base, it contains: tin, molybdenum, lead, arsenic, tungsten, copper, nickel, cobalt, manganese, arsenic, titanium, phosphorus, silicon, aluminum There are 15 elements in total.

[0029] (2) Austenitic stainless steel ST21-28 series, 8 pieces, adding elements niobium and tantalum.

[0030] (3) Nickel-chromium-molybdenum-copper stainless steel, 5 pieces, with high copper content and added elements of antimony and vanadium.

[0031] (4) GH2132 (US brand A286), 4 pieces, with high nickel content and low copper content, high titanium content and low vanadium content.

[0032] (5) GH2036 iron-based superalloy, 5 pieces, high manganese content

[0033] (6) W18Cr4V high-speed tool steel, 5 pieces, with high tungsten content.

[0034] (7) Low-alloy steel GSBH40067-93, 7 pieces, wit...

Embodiment 2

[0053] Application of nickel base alloy

[0054] Step 1: This embodiment selects the following standard samples:

[0055] (1) GH3044, 5 pieces, high tungsten solid solution strengthened alloy.

[0056] (2) DZ125, 5 pieces, directionally solidified alloy, high tungsten, tantalum, molybdenum, cobalt strengthened solid solution matrix, and contains high content of aluminum and titanium to form Ni3 (Al, Ti) (γ' phase) aging strengthening alloy.

[0057] (3) GH4169 (Inco718 alloy in the United States), 5 pieces, high niobium content, forming a Ni3Nb (γ” phase) strengthening phase, used for turbine disks, compressor disks, compressor blades, etc., is the most used alloy in aero-engines.

[0058] (4) GH4049, 5 pieces, deformed turbine blade material with high content of molybdenum, tungsten, cobalt, aluminum and titanium.

[0059] (5) N263 (China GH163), 5 pieces, solid solution strengthening alloy with high molybdenum and cobalt, combustion chamber materials.

[0060] (6) C1023 (...

Embodiment 3

[0086] Application of Copper Alloy

[0087] Step 1: This embodiment selects the following standard samples:

[0088] (1) Aluminum bronze, 9 pieces, is characterized by a wide range of aluminum, nickel, and paste elements, and there are many types of elements, including 12 elements.

[0089] (2) Silicon brass, 6 pieces, containing sulfur, antimony, bismuth elements and high content of zinc and silicon elements.

[0090] (3) Gun metal, 5 pieces, with high content of tin, lead and zinc elements, and low content of bismuth, silver and antimony.

[0091] (4) Nickel silver, 5 pieces, characterized by a high content of nickel and zinc elements, with a nickel content of 20.9%.

[0092] (5) QA110-4-4 aluminum-iron-nickel bronze, 5 pieces.

[0093]Step 2: Sample preparation: The sample is ground, and the surface is ground into a smooth plane with consistent texture. In order to avoid the interference of the abrasive on the low content of Al and Si elements in the sample preparation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com