High-temperature air pressure sintering furnace

A gas pressure sintering, high temperature technology, applied in furnaces, electric furnace heating, furnace components, etc., can solve the problems of easily damaged heating elements, easy oxidation, arcing, etc., to achieve a furnace with light weight, good thermal insulation effect, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

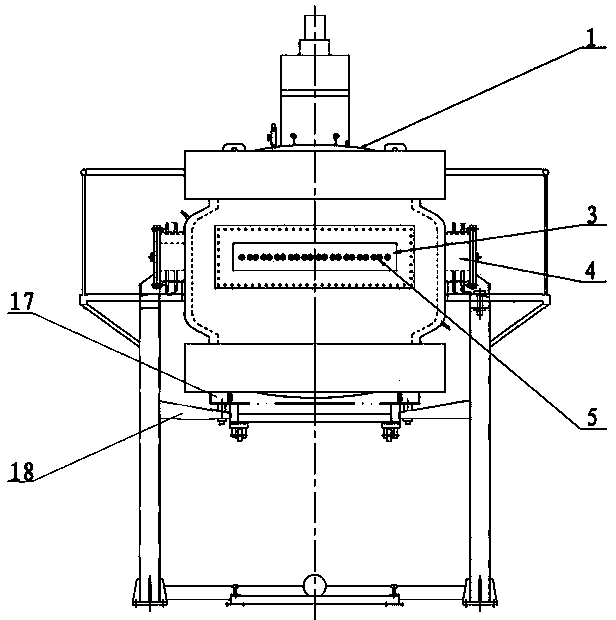

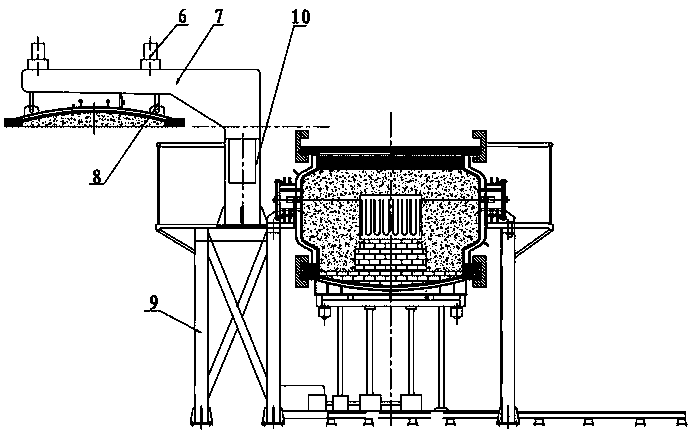

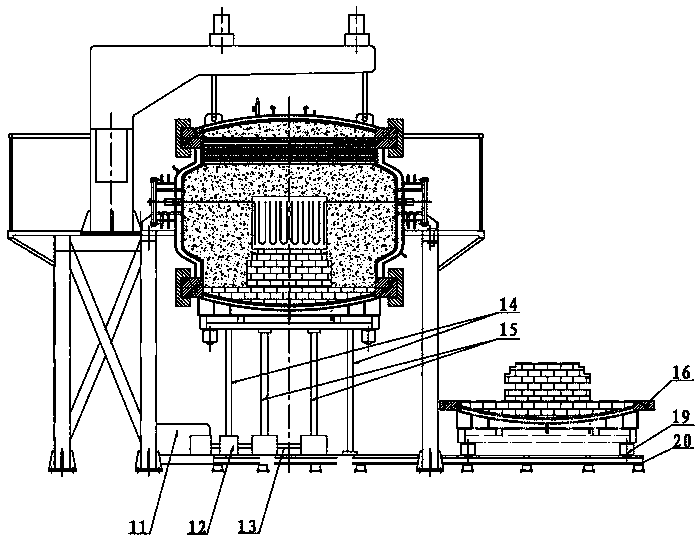

[0018] As shown in the figure: a high-temperature pressure sintering furnace, including a furnace, a furnace body, a furnace cover 1, a heating element 2, a hydraulic lift and translation system for the furnace cover, and a bottom lift and translation system. The furnace is a double-layer structure. The inner layer of the furnace is made of hollow spherical alumina bricks. The top of the furnace is made of high-strength and high-temperature resistant ceramic fiber boards. The outer layer of the furnace is composed of high-temperature ceramic fibers and low-temperature ceramic fibers in turn from the inside to the outside, so that the quality of the entire furnace is greatly reduced. , The heat preservation effect is significantly improved. like figure 2 As shown, the furnace cover hydraulic lifting and translation system includes a hydraulic cylinder 6, a lifting arm 7, a sling 8, a rotating support frame 9 and a rotating support 10, and the furnace cover hydraulic lifting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com