Strong emulsibility microbe wax cleaning and preventing bacterial agent and application thereof

A technology of emulsification and wax fungicide, which is applied in the direction of cleaning utensils, drilling compositions, chemical instruments and methods, etc., and can solve the problems of slow paraffin speed, short contact time, and limited wax-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

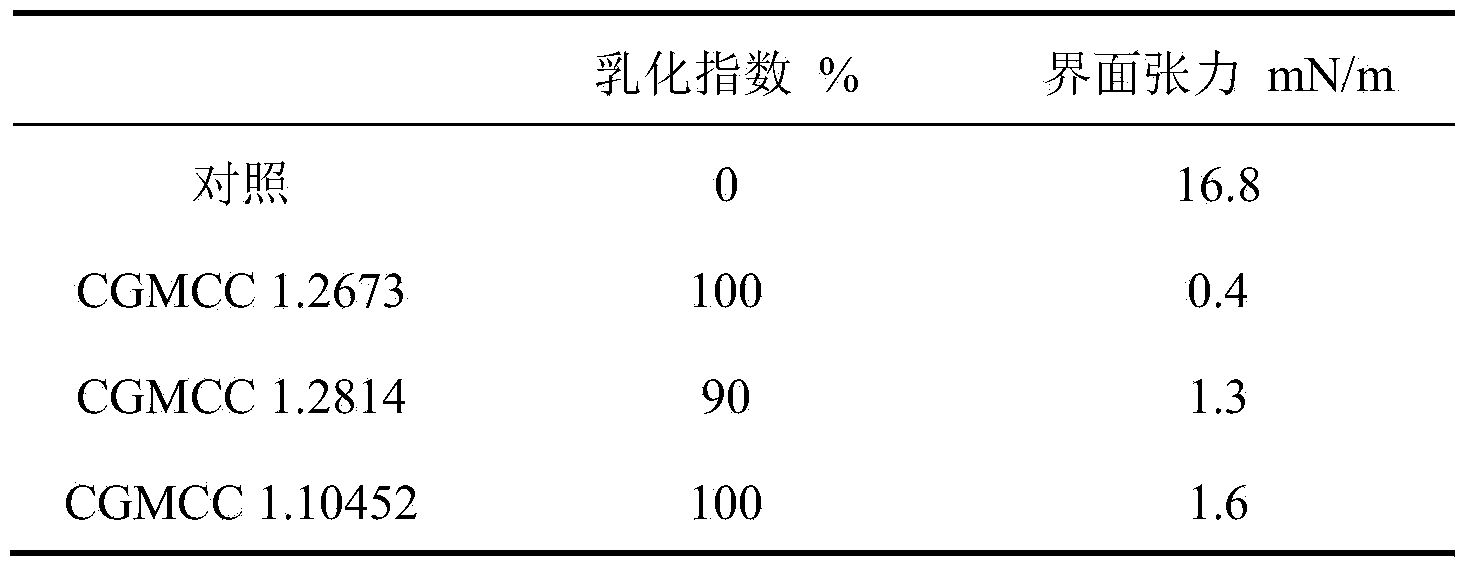

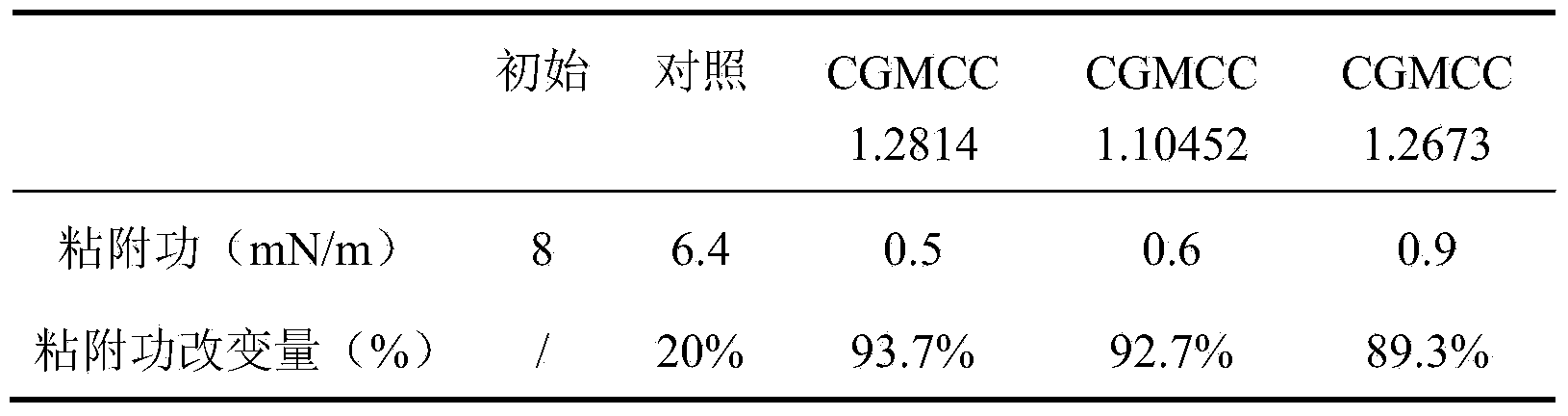

[0032] In the present embodiment, the strong emulsifying microbial anti-wax agent is composed of Pseudomonas aeruginosa N1 (CGMCC 1.2814), Pseudomonas aeruginosa N2 (CGMCC 1.10452) and surface bacillus (CGMCC 1.2673), 3 strains All were purchased from China General Microorganism Culture Collection Management Center (CGMCC). The bacterial agents are solid dry powders. The three bacteria are stored separately, and skim milk is used as the protective agent and carrier. The mass ratio of the three bacterial dry powders is 1:1:1. .

[0033] In the present embodiment, the application of the strong emulsifying microbial anti-wax agent in oil production comprises the following steps:

[0034] (1) Activate each strain separately until the cell concentration of each strain reaches 3.2~4.6×10 8 Each bacterial solution (2L) was mixed in equal volumes, and then the compound bacterial solution was added to the fermentation medium at a volume ratio of 1:10, fermented and cultivated at 40°C ...

Embodiment 2

[0040] In the present embodiment, the strong emulsifying microbial anti-wax agent is composed of Pseudomonas aeruginosa N1 (CGMCC 1.2814), Pseudomonas aeruginosa N2 (CGMCC 1.10452) and surface bacillus (CGMCC 1.2673), 3 strains All were purchased from China General Microorganism Culture Collection Management Center (CGMCC). The bacterial agents were in liquid state and stored separately. 8 individual / mL.

[0041] In the present embodiment, the application of the strong emulsifying microbial anti-wax agent in oil production comprises the following steps:

[0042] (1) Mix equal volumes of the bacteria liquids of various strains, transfer the compound bacterial liquids to the fermenter, add fermentation medium at a volume ratio of 1:10, ferment and cultivate at 35°C for 72 hours, and control the pH value at 6~ 8. There is no need to pass oxygen or air during the fermentation process. After the fermentation is completed, the next stage of fermentation is carried out. The volume r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com