Compound nonionic surfactant

A non-ionic surface and active agent technology, applied in the direction of dissolution, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited practical application and insufficient comprehensive performance, and achieve strong emulsifying ability, good low temperature fluidity, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

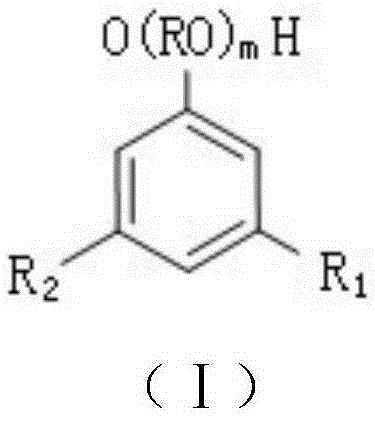

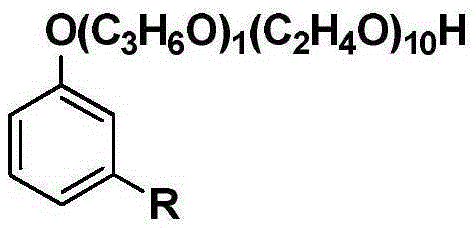

Method used

Image

Examples

Embodiment 1

[0033] A compounded nonionic surfactant is compounded by the following components by weight: 80% of component A and 20% of component B. Wherein component A is cardanol polyoxyethylene ether-6, and component B is isomeric C10 alcohol polyoxyethylene ether-5.

Embodiment 2

[0035] A compounded nonionic surfactant is compounded by the following components in parts by weight: 50% of component A and 50% of component B. Wherein component A is cardanol polyoxyethylene ether-7, and component B is isomeric C10 alcohol polyoxyethylene ether-7.

Embodiment 3

[0037] A compounded nonionic surfactant is compounded by the following components in parts by weight: 60% of component A and 40% of component B. Among them, component A is cardanol polyoxyethylene ether-1160%, and component B is isomeric C13 alcohol polyoxyethylene ether-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com