Method for carbon monoxide gas phase synthesis of oxalate

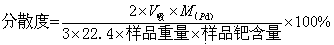

A carbon monoxide, gas phase synthesis technology, applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the active component Pd dispersion and crystallite content Low, low space-time yield of synthetic oxalate, etc., to achieve the effect of improving catalytic activity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 60 g of the alumina support calcined at 1100° C. for 4 hours. Prepare 50 ml of a solution containing 0.03 mol / L palladium chloride and 0.05 mol / L lanthanum nitrate, adjust the pH to 4.0 with 10% (weight) sodium carbonate, and add 1 g tartaric acid to obtain impregnation solution I. Slowly add the impregnating solution I into the carrier, and turn the carrier to make the solution impregnate evenly, so as to prepare the catalyst precursor. The catalyst precursor was aged in air for 20 hours, dried at 80°C, and then calcined in a muffle furnace at 450°C to obtain the catalyst cat-1A for gas-phase synthesis of oxalate from carbon monoxide.

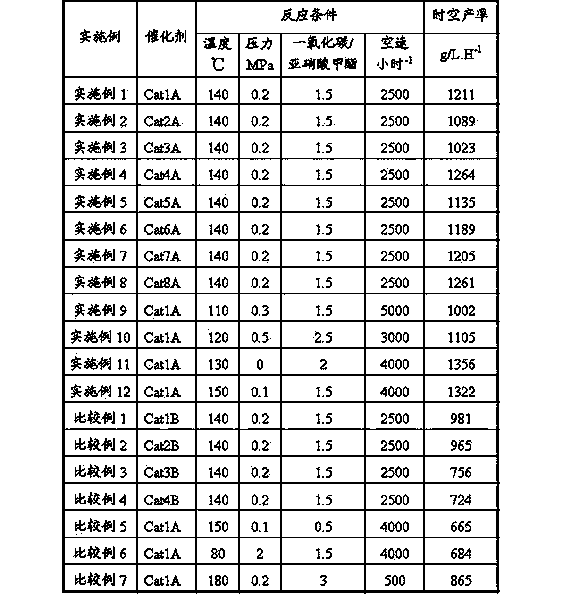

[0038] Get 40g and make catalyst and pack in reaction tube, feed hydrogen volume space velocity and be 500 hours -1 , the temperature was programmed to 200°C for 6 hours for reduction. Then at a reaction temperature of 140°C, a reaction pressure of 0.2 MPa, a molar ratio of CO to methyl nitrite of 1.5, and a volumetric space velo...

Embodiment 2~8

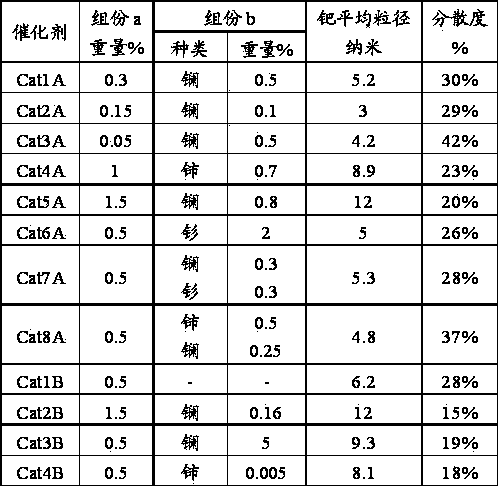

[0041] According to the preparation method of [Example 1], the catalyst cat-2~8A was prepared only by changing the palladium content of the catalyst, the type and content of the auxiliary agent. See Table 1 for the weight percentage composition of each component of the catalyst and the microcrystalline content and dispersion of palladium, and see Table 2 for the synthesis reaction conditions.

[0042]

Embodiment 9~12

[0044] Use the catalyzer of [embodiment 1], just change the condition of synthetic reaction. See Table 1 for the weight percentage composition of each component of the catalyst and the microcrystalline content and dispersion of palladium, and see Table 2 for the synthesis reaction conditions.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com