Manufacturing method of complex-structured intelligent material device based on rapid forming technique

A technology of complex structure and intelligent materials, applied in the direction of improving energy efficiency and process efficiency, can solve the problems of long forming time, simple structure, single shape of forming materials, etc., and achieve the effect of high forming precision and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

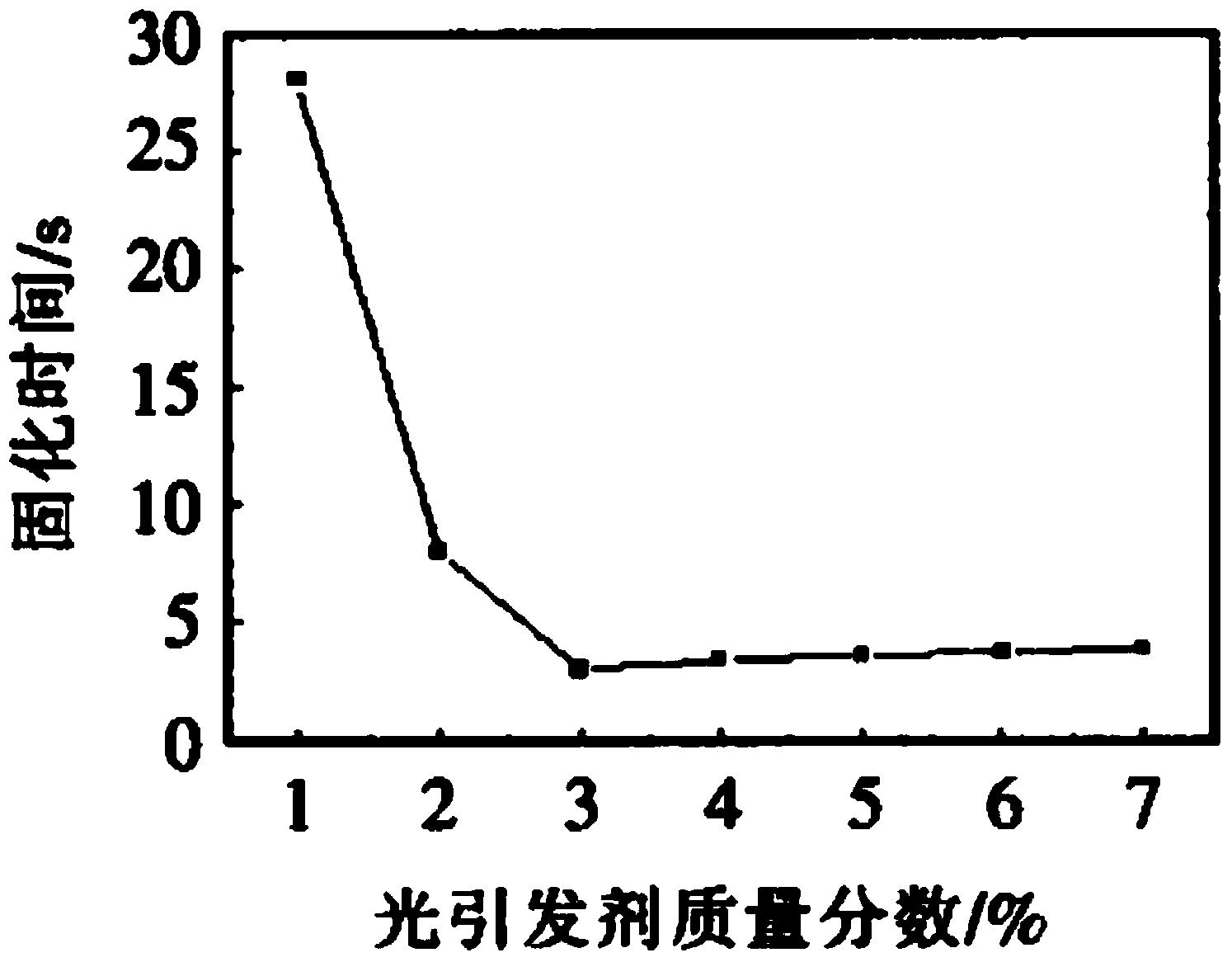

[0063] 1) The power source of the helical thin-walled spring is a kilovolt DC voltage. It works in an anhydrous and room temperature environment. When the output is required to provide deformation and be used as a driver, polyacrylate dielectric elastic material is selected as the forming raw material. ; The polyacrylate dielectric elastic material consists of 87 parts by mass of liquid epoxy acrylate, 10 parts of liquid trimethylolpropane triacrylate and 3 parts of isopropyl thioxanthone; liquid epoxy acrylate and liquid trimethylolpropane triacrylate can be cured by isopropyl thioxanthone as a photoinitiator under light conditions; figure 1 The curve of curing speed of photosensitive material with the content of photoisopropyl thioxanthone is shown, determine the content of photoisopropyl thioxanthone, and select the appropriate ratio of liquid epoxy acrylate and liquid trimethylolpropane triacrylate , and finally determine the formulation of the light polyacrylate dielectri...

Embodiment 2

[0071] 1) When the working environment of the minimally invasive surgery manipulator model of the smart material device is water and room temperature, the forming raw material used is a sheet-like ionic polymer-metal composite material;

[0072] 2) Since the forming raw material used is a sheet-like ionomer-metal composite material, and the single-layer thickness of the material is 0.1mm, when the rapid prototyping process is selected as the laminated entity manufacturing process, its process parameters: cutting speed is 400 ~650mm / s, the lifting speed of the platform is 20~60mm / s, and the temperature of the heating roller is 180~220℃; the process parameters of the preferred laminated entity manufacturing process: the cutting speed is 550mm / s, and the lifting speed of the platform is 45mm / s , the temperature of the heating roller is 200°C;

[0073]3) Convert the two-dimensional pattern of the minimally invasive surgery arm to form a three-dimensional model of the minimally inv...

Embodiment 3

[0076] 1) The power source of the sphere with holes is thermal energy, the working environment is 10-70°C, and the molding raw material used is powdered shape-memory vinyl-vinyl chloride copolymer resin material;

[0077] 2) Since the forming raw material used is a powdered shape memory vinyl chloride copolymer resin material, when the selected rapid prototyping process is a selective laser sintering process, the process parameters are: the thickness of a single layer of powder is 0.1-0.3mm, using Progressive scanning mode, scanning speed is 400 ~ 6000mm / s. The optimized process parameters of the laser sintering process are: the thickness of single-layer powder coating is 0.2mm, the progressive scanning method is adopted, and the scanning speed is 2800mm / s;

[0078] 3) Carry out laser scanning and CT tomographic scanning on the sphere entity with holes to obtain point cloud data, and then use reverse engineering to construct a 3D model of the sphere with holes; after the 3D mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com