Low-energy-consumption oxygen-enriched combustion system coupling solar energy and chemical loop air separation

A technology coupled with solar energy and oxygen-enriched combustion, applied in solar thermal power generation, combustion equipment, combustion methods, etc., can solve problems such as high energy consumption of the system, lower efficiency of the oxygen-enriched combustion system, and less oxygen production, and achieve easy capture , Avoid flue gas recirculation loop, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

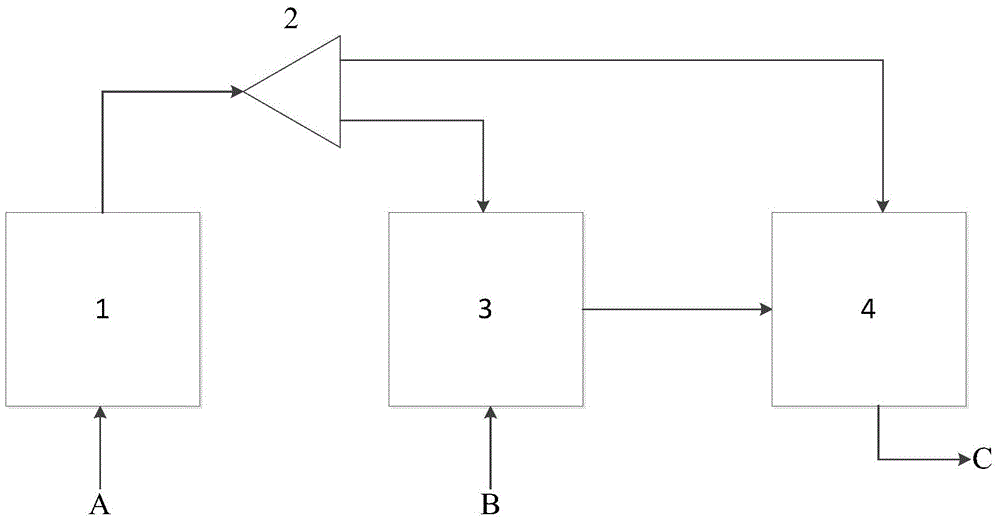

[0050] The low-energy oxygen-enriched combustion system coupled with solar energy and chemical looping air separation technology of this example includes a dry steam production unit 1, a chemical looping air separation unit 3 and an oxygen-enriched combustion unit 4, and the dry steam production unit 1 is used to produce The dry steam required for the reaction is taken, the chemical looping air separation unit 3 is used to separate high-purity oxygen, and the oxygen-enriched combustion unit 4 is used for oxygen-enriched combustion and the capture of carbon dioxide. The oxygen carrier used is a copper-based oxygen carrier.

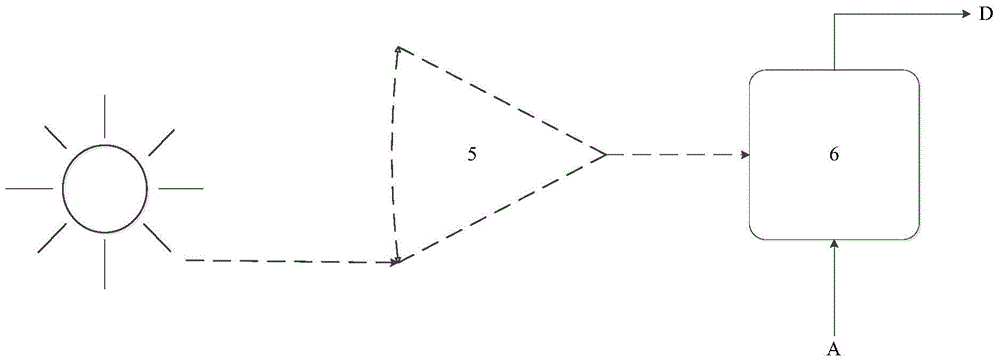

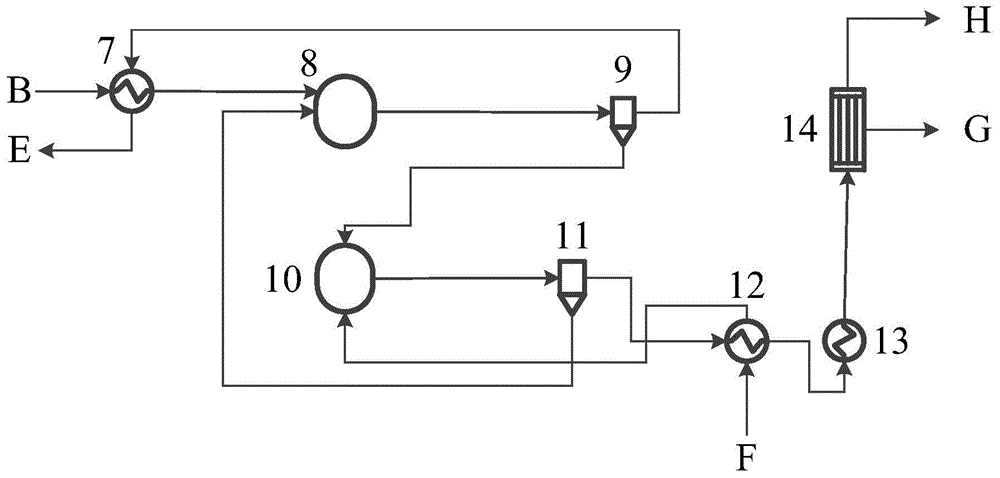

[0051] The dry steam production device 1 includes a solar heat collector 5, a steam generator 6 and a flow divider 2. The water fed into the steam generator 6 generates dry steam under the action of the heat of the solar heat collector 5, and the dry steam passes through the flow divider for 2 minutes. It is two streams: one dry steam F enters the chemical l...

Embodiment 2

[0055] This example includes dry steam production unit, chemical looping air separation unit, conventional air separation unit and oxygen-enriched combustion unit, and its difference with embodiment one is that this system also includes conventional air separation unit, conventional air separation unit and chemical The chain air separation unit together provides the high-purity oxygen required by the oxyfuel combustion unit.

[0056] Using the oxygen-enriched combustion system described in this embodiment, realizing a clean and low-energy-consumption oxygen-enriched combustion method mainly includes the following steps:

[0057] a) Utilize the trough type solar heat collector 5 to collect solar energy, the steam generator 6 utilizes the collected solar energy to produce dry steam, the dry steam is divided into two strands through the splitter 2, and one strand of dry steam F enters the chemical chain air separation unit 3 As the fluidizing gas in its oxygen release reactor 10,...

Embodiment 3

[0064] In this example, dry steam is produced by using a solar dry steam production device, and the circulating flue gas and dry steam are put into the oxygen release reactor of the chemical looping air separation system as fluidization gas, and the oxygen partial pressure is controlled to produce oxygen-enriched mixed gas. It then goes into the boiler unit where it reacts with the fuel.

[0065] a) Utilize the trough solar collector 5 to collect solar energy, and the steam generating device 6 utilizes the collected solar energy to produce dry steam, and the dry steam is divided into two streams through the splitter 2, and one stream of dry steam F passes through the mixer 18 and the circulating smoke Gas mixing enters the chemical looping air separation unit 3 as the fluidization gas in its oxygen release reactor 10, and another stream of dry steam 1 enters the oxygen-enriched combustion unit;

[0066] b) The fluidization gas of the oxygen absorption reactor 8 is air, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com