Method for preparing platinum-nickel nucleocapsid structure fuel cell catalyst through microwave reduction

A core-shell structure, fuel cell technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high production cost, high price, low platinum utilization rate, etc., and meet the experimental conditions The effect of easing, low production cost and high utilization rate of platinum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

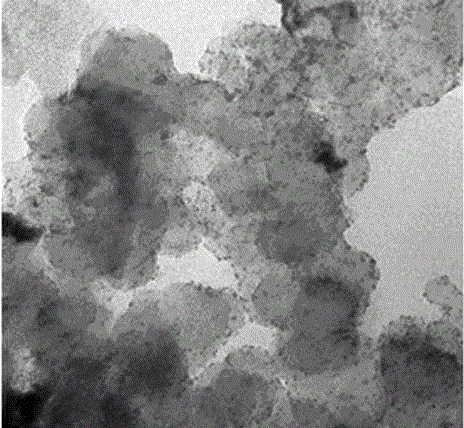

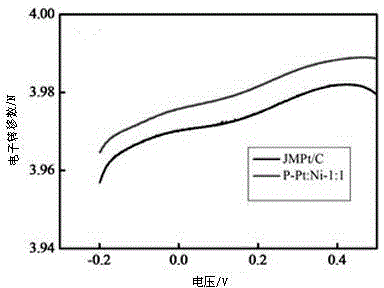

Image

Examples

Embodiment 1

[0030] A method for preparing a fuel cell catalyst with a platinum-nickel core-shell structure by microwave reduction, comprising the following steps:

[0031] Step 1: Add 18.8mg of carbon powder into 50ml of ethylene glycol solvent, then add 1.88mg of polyvinylpyrrolidone, under the condition of ultrasonic frequency of 20KHz, ultrasonic power of 200W, ultrasonic time of 30min, mix well to obtain mixture A ;

[0032] Step 2: Add 10 mg of nickel acetate (nickel element is 2.3 mg) to mixture A, and stir for 30 minutes at a temperature of 35 °C and a stirring speed of 150 r / min to obtain a mixture B;

[0033] The third step: Microwave irradiation is carried out on the mixture B, the reaction temperature is 200°C, the reaction time is 2min, and then left to cool to obtain the mixture C;

[0034] Step 4: Add 3.9 mg of chloroplatinic acid (the platinum element is 2.3 mg) into mixture C, and stir for 30 minutes at a temperature of 35° C. and a stirring speed of 150 r / min to obtain a...

Embodiment 2

[0038] The steps of this embodiment are the same as those of Example 1, except that the nickel acetate added in step 2 is 30 mg.

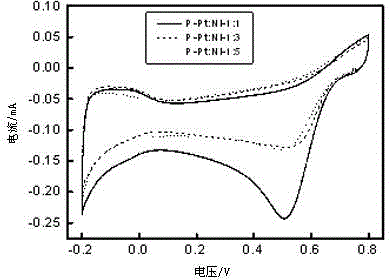

[0039] The cyclic voltammogram of the platinum-nickel core-shell structure fuel cell catalyst material prepared in this embodiment is as follows figure 2 As shown, the open circuit potential is 0.68V, and the oxygen reduction peak is about 0.53V.

Embodiment 3

[0041] The steps of this embodiment are the same as those of Example 1, except that the nickel acetate added in step 2 is 50 mg.

[0042] The cyclic voltammogram of the platinum-nickel core-shell structure fuel cell catalyst material prepared in this embodiment is as follows figure 2 As shown, the open circuit potential is 0.69V, and the oxygen reduction peak is about 0.54V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com