A method for extracting active ingredients of natural products by mixing ethanol and subcritical fluid

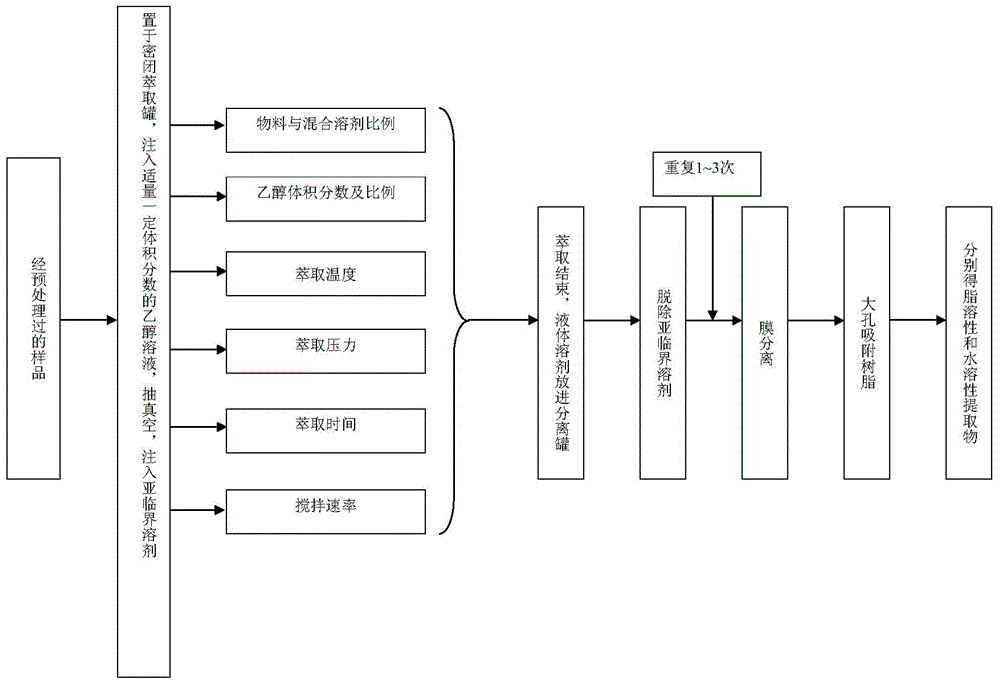

A subcritical fluid and natural product technology, which is applied in the extraction of active ingredients of natural products by mixing ethanol and subcritical fluid, and simultaneously extracts water-soluble and fat-soluble active ingredients in natural products. Both water-soluble and fat-soluble active ingredients are extracted, the water-soluble ingredients cannot be fully extracted, and the polysaccharide structure is destroyed, so as to achieve the effect of increasing selectivity and efficiency, short cycle time and high extraction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 200g of Robinia pseudoacacia (water content <13%), pulverize and pass through an 80-mesh sieve, place it in a closed extraction tank, add 1800mL of ethanol with a volume fraction of 70%, close the feed channel, evacuate to vacuum, and pour into the extraction tank Dimethyl ether solvent, completely immerse the material, the mass volume ratio (w / v / v) of the added amount of the material, subcritical dimethyl ether and ethanol solution is 1:6:9. At a temperature of 25°C (pressure is the corresponding saturated vapor pressure at the corresponding temperature), and the stirring rate is 700 rpm, the extraction is performed for 50 minutes; after the extraction is completed, slowly put the mixed solvent into the separation tank, and separate the extraction tank and the separation tank. Evaporation and desolvation treatment is carried out to finally obtain an extract containing both fat-soluble components and water-soluble components. The subcritical solvent removed from the...

Embodiment 2

[0032] Take 200g of dried mulberry leaves (water content <13%), pulverize and pass through an 80-mesh sieve, place it in a closed extraction tank, add 400mL of ethanol with a volume fraction of 70%, close the feed channel, pump to vacuum, and extract The dimethyl ether solvent is injected into the tank to completely immerse the materials. The mass-volume ratio (w / v / v) of the added amount of the materials, subcritical dimethyl ether and ethanol solution is 1:13:2. Extract for 30 minutes at a temperature of 45°C (the pressure is the saturated vapor pressure corresponding to this temperature) and a stirring rate of 600 rpm; after the extraction, put the mixed solvent into the separation tank, and evaporate the extraction tank and the separation tank respectively. For processing, inject 400 mL of 70% ethanol into the extraction tank again, evacuate, and inject dimethyl ether solvent for extraction. Repeat three times to obtain an extract containing both fat-soluble components and w...

Embodiment 3

[0035] Take 1000kg of dried eucommia bark (water content <13%), smash it through a 100-mesh sieve, and place it in a closed extraction tank, add 70% ethanol solution, vacuum, and pour butane solvent into the tank Completely immersed, the mass-volume ratio (w / v / v) of the added amount of materials, subcritical butane and ethanol solution is 1:5:5, and the extraction conditions are: time 30min, temperature 30℃ (pressure corresponds to this temperature Saturated vapor pressure), and the stirring rate is 500 rpm. After the extraction, the mixed solvent is put into the separation tank, and the extraction tank and the separation tank are respectively subjected to evaporative desolventizing treatment. After desolventizing is completed, an extract of Eucommia bark containing both fat-soluble and water-soluble components is obtained. The remaining steps are the same as above. Among them, the 200nm inorganic ceramic membrane (alumina membrane) effectively intercepts fat-soluble components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com