Fuel battery and preparation method thereof

A fuel cell and fuel technology, used in fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve the problems of fuel cell life impact, complex water management, and low reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] I provided in this embodiment - / I 3 - Redox couple type cathode fuel cell single cell, its main feature is I - / I 3 - The redox couple molecules are used as the cathode reaction medium to replace the traditional oxygen as the direct electroreduction of the cathode reactant, and the recovery of the couple molecules relies on photocatalysis. see figure 1 , the single cell is composed of a catalytic layer, an ion exchange membrane 2, a flow field plate and a photocatalytic electrode 4, wherein: the cathode and anode catalysts are respectively coated on both sides of the ion exchange membrane 2 to form a cathode catalytic layer 3, an anode catalytic layer 1, and an anode The catalyst layer 1, the ion exchange membrane 2 and the cathode catalyst layer 3 constitute a membrane electrode. Then the membrane electrode is placed between the anode flow field and the cathode flow field, and the membrane electrode, the anode flow field and the cathode flow field are connected ...

Embodiment 2

[0033] The I provided by above-mentioned embodiment 1 - / I 3 - A redox couple type cathode fuel cell is prepared by the following method, the steps of which include:

[0034] 1. Preparation of Membrane Electrode:

[0035] Add 1g of Pt / C catalyst into 13ml of deionized water and stir vigorously, then add 6.7ml of Nafion solution into it, heat the resulting mixture for 30min, then perform sonication treatment, and homogenize the mixture for 1h to obtain a catalytic layer Homogenate, spray the obtained catalytic layer homogenate onto the PTFE film, dry at 60°C for 10min and then dry in N 2 Heat at 90° C. for 3 minutes under ambient conditions to form a catalytic layer, transfer the obtained catalytic layer to the ion exchange membrane 2 at 125° C. and 10 MPa, and press hot to obtain a membrane electrode.

[0036] 2. Single battery assembly:

[0037] The conductive end plate, flow field plate, gasket and membrane electrode are assembled into a single cell in sequence. The pu...

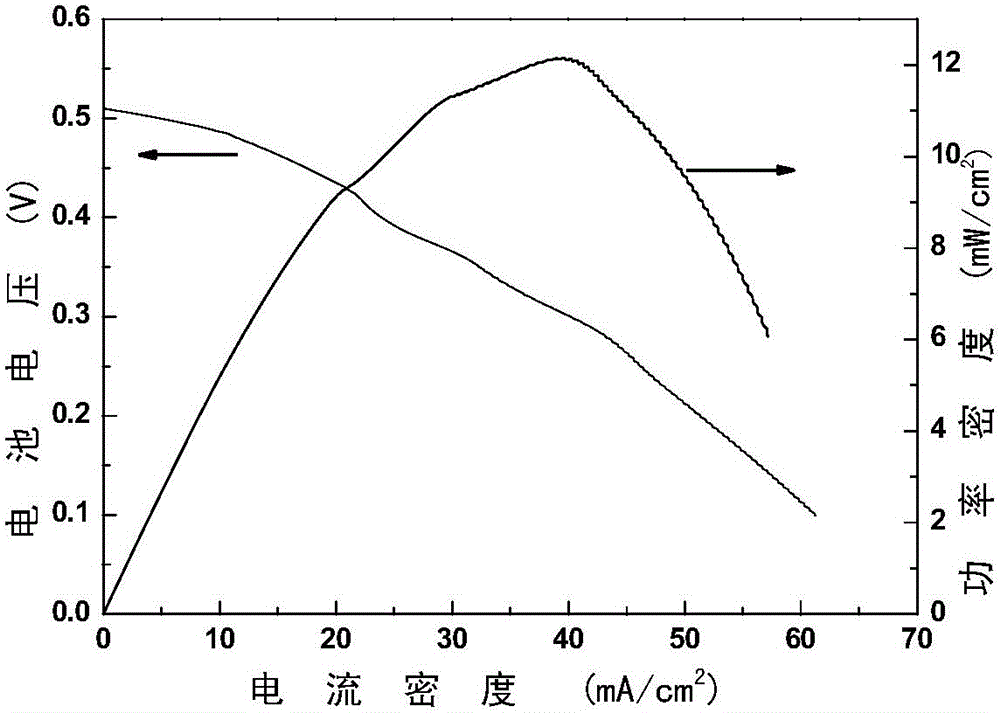

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com