High-performance sulfenyl composite anode material and preparation method thereof

A composite positive electrode material and composite material technology, applied in the field of high-performance sulfur-based composite positive electrode material and its preparation, can solve the problems of poor cycle life, low electrode activity, low electrical conductivity, etc., and achieve low cost, low specific surface area, thermal good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

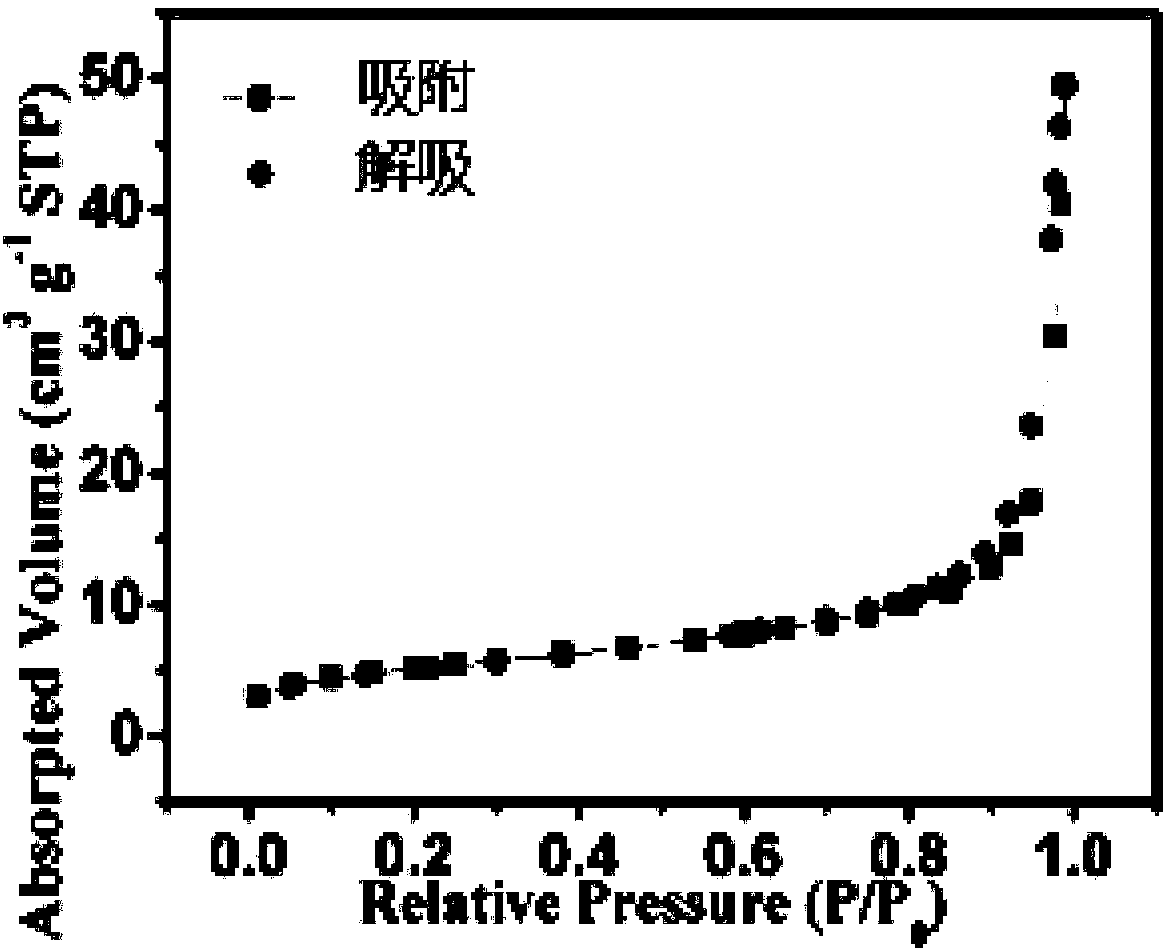

[0023] The selenium element, the sulfur element and the conductive polymer are uniformly mixed according to the mass ratio of 20P 80 (10Se 90S) (the mass percentage of the conductive polymer in the mixture is 20%, the mass percentage of the selenium element is 8%, and the sulfur The mass percentage of the simple substance is 72%), heat treatment at 220° C. for 10 h under a vacuum-sealed condition, to fully react sulfur, selenium and conductive polymer, and obtain a precursor. Then, the precursor was treated at 300°C for 4 hours in an argon or nitrogen atmosphere to promote dehydrogenation of the polymer, and volatilize and remove S that was not recombined with the polymer chain to obtain a sulfur-based composite cathode material. According to its BET results, its specific surface area is 18m 3 / g( figure 1 ).

[0024] The above-mentioned sulfur-based composite positive electrode material, acetylene black conductive agent, and SBR adhesive are mixed evenly at a mass ratio of ...

Embodiment 2

[0026] The selenium element, the sulfur element and the conductive polymer were uniformly mixed at a mass ratio of 65P·35(2Se·98S), and heat-treated at 250°C for 12 hours in a vacuum-sealed condition to fully react the sulfur, selenium and the conductive polymer to obtain a precursor. Then, the precursor was treated at 350°C for 10 hours under an argon or nitrogen atmosphere to promote dehydrogenation of the polymer, and volatilize and remove the S that was not recombined with the polymer chain to obtain a sulfur-based composite cathode material.

Embodiment 3

[0028] The selenium element, the sulfur element and the conductive polymer were uniformly mixed at a mass ratio of 50P·50(5Se·95S), and heat-treated at 280°C for 16 hours in a vacuum-sealed condition to fully react the sulfur, selenium and the conductive polymer to obtain a precursor. Then, the precursor was treated at 400°C for 6 hours under an argon or nitrogen atmosphere to promote dehydrogenation of the polymer, and volatilize and remove S that was not recombined with the polymer chain to obtain a sulfur-based composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com