Blast furnace coal injection combustion improver and use method thereof

A technology of blast furnace coal injection and combustion accelerant, which is applied in the field of metallurgy and ironmaking, can solve problems such as adverse effects of smelting, corrosion of blast furnace equipment and gas pipelines, increase of alkali load of blast furnace, etc., to speed up oxygen diffusion speed, increase energy release rate, The effect of promoting the cleavage of macromolecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

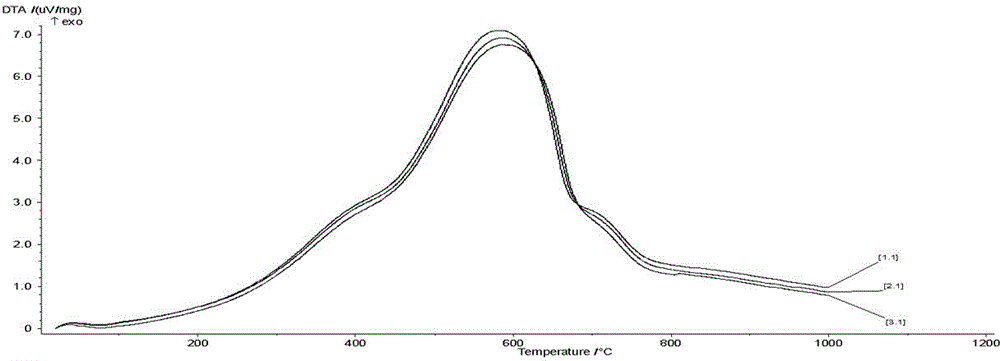

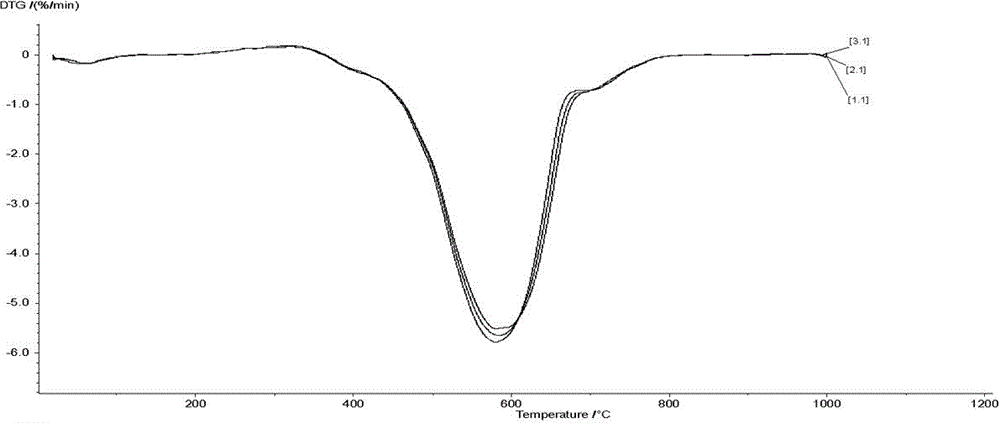

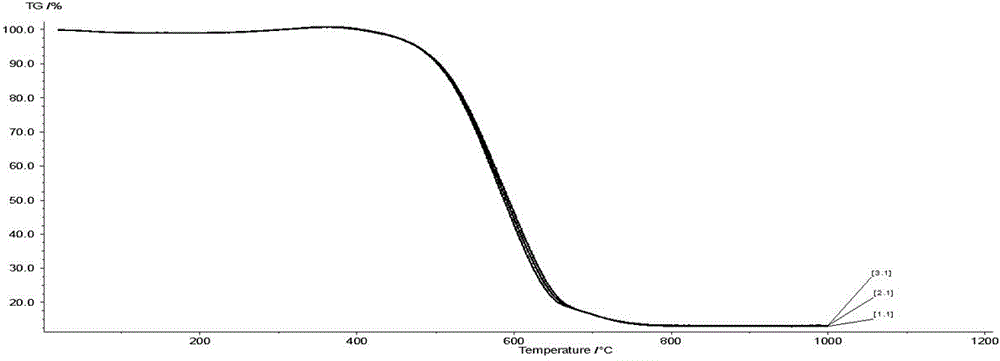

Image

Examples

Embodiment 1

[0023] On March 20, 2014, in the raw material laboratory of Kunming Iron and Steel Technology Center, the combustion performance test was carried out by adding ALJ coal injection combustion aid (coal injection combustion aid of the present invention) to coal powder.

[0024] Combustibility test

[0025] Analysis method: QB-0031-2005

[0026] According to the test method of carbon residual weighing method after combustion, the combustion-supporting effect of adding ALJ coal-injected combustion-supporting agent was tested, and the details are as follows:

[0027] Test conditions

[0028] The temperature of the muffle furnace is about 900°C. The sample is put into the muffle furnace and burned for 3 minutes, taken out, and weighed after cooling.

[0029] Test Principle

[0030] The same weight of pulverized coal is heated and burned at the same time and under the same temperature and environmental conditions. The weight lost is approximately equal to the weight of the complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burn rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com