A kind of highly transparent antistatic PET polyester film and preparation method thereof

A polyester film and antistatic technology, which is applied in the field of polyester film and its preparation, can solve the problems of thin antistatic layer, increased cost, and time limit of antistatic performance, so as to improve antistatic performance and antistatic performance , high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

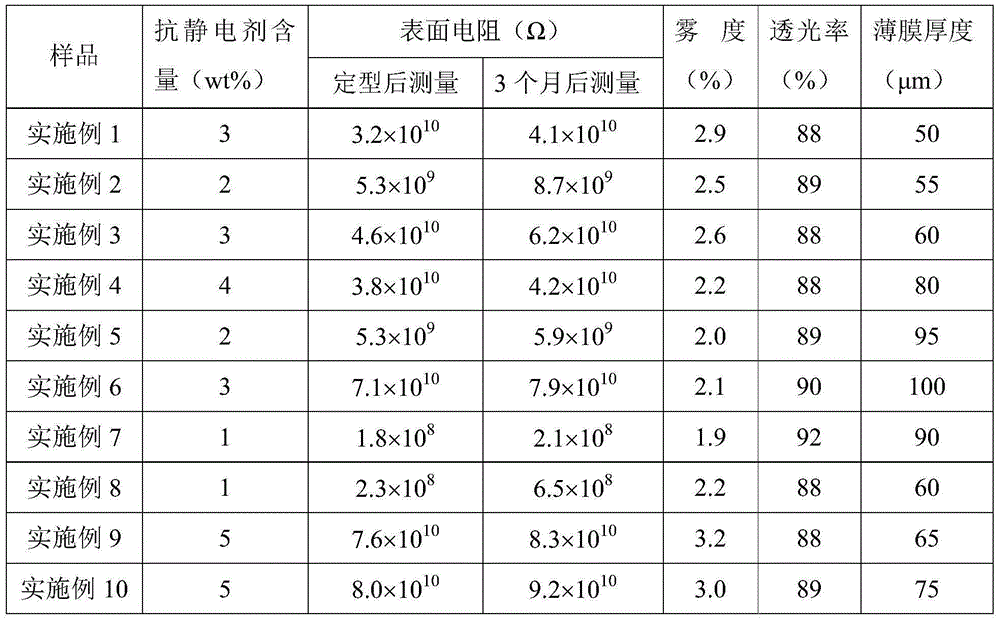

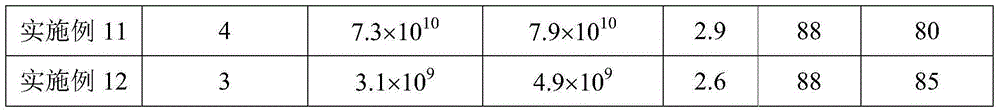

Examples

preparation example Construction

[0029] The preparation method of PET polyester film of the present invention comprises the following steps:

[0030] 1) Perform block copolymerization of terephthalic acid, ethylene glycol and polyether, and process the obtained copolymer through twin-screw extrusion granulation to obtain antistatic masterbatch, which is an antistatic agent;

[0031] 2) Vacuum-dry the PET polyester chips and antistatic masterbatch, remove the water, take the antistatic masterbatch and PET polyester chips and mix them evenly, and then add antioxidants to mix, wherein the antistatic masterbatch, PET polyester chips and antistatic The composition ratio of oxygen agent is 1~5:95~99:0.1;

[0032] 3) The mixture obtained in step 2) is extruded into a thick film through twin-screw, and the thick film is shaped after biaxial stretching to obtain the highly transparent and antistatic PET polyester film.

[0033] Preferably, the temperature in the twin-screw extrusion process in step 3) is 260-280°C, a...

Embodiment 1

[0045] Copolymerize terephthalic acid, ethylene glycol and PEG1000 to synthesize PET-b-PEG1000 block copolymer, and the content of PEG1000 in the copolymer is 35wt%. The obtained block copolymer is subjected to twin-screw extrusion and granulation to obtain an antistatic masterbatch, which is an antistatic agent. Vacuum dry PET polyester chips and antistatic masterbatch to remove moisture. Take 3 parts of antistatic masterbatch, 97 parts of PET polyester chips, and 0.1 part of antioxidant 1010 and mix them. The mixture is extruded into a thick film through twin-screw. The extrusion temperature of the screw was 260°C, and the temperature of the roller was 70°C. After the obtained thick film was biaxially stretched, it was fixed at 120° C. for 3 minutes to obtain an antistatic film.

Embodiment 2

[0047] Copolymerize terephthalic acid, ethylene glycol and PEG1000 to synthesize PET-b-PEG1000 block copolymer, and the content of PEG1000 in the copolymer is 35wt%. The obtained block copolymer is subjected to twin-screw extrusion and granulation to obtain an antistatic masterbatch, which is an antistatic agent. Vacuum dry PET polyester chips and antistatic masterbatch to remove moisture. Take 2 parts of antistatic masterbatch, 98 parts of PET polyester chips, and 0.1 part of antioxidant 1010 and mix them. The mixture is extruded into a thick film through twin-screw. The extrusion temperature of the screw was 270°C, and the temperature of the roller was 75°C. After the obtained thick film was biaxially stretched, it was fixed at 130° C. for 4 minutes to obtain an antistatic film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com