Transparent impact-resistance polystyrene and preparation method thereof

A polystyrene, impact-resistant technology, applied in the field of thermoplastic materials, can solve the problems that affect the service life and application range of transparent high-impact polystyrene materials, low hardness and rigidity, poor transparency, etc., to achieve good durability Folding and tear resistance, good dimensional stability, good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

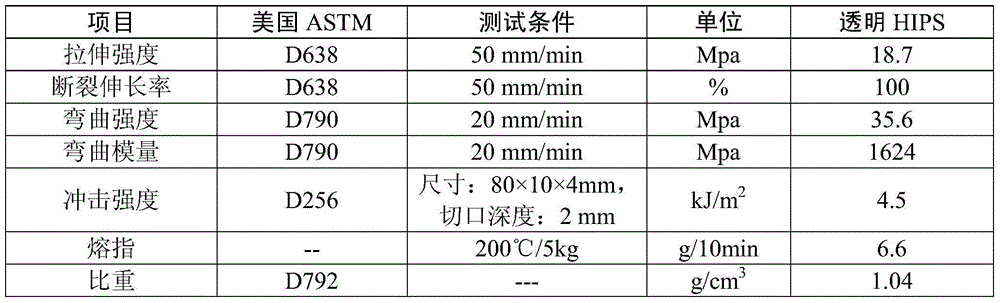

Image

Examples

Embodiment 1

[0037] (1) Prepare raw materials according to the following percentages by weight:

[0038] GPPS25%, K glue 69.1%, SMA0.5%, toughening agent 5%, lubricant 0.2%, coupling agent 0.1%, antioxidant 0.1%;

[0039] The GPPS is Chimei’s PG-383; the K glue is Zhonghe’s SL-803G; the SMA is SMA-700 from Shanghai Huawen Electronic New Material Co., Ltd.; the toughening agent is SBS produced by Yueyang Petrochemical -792; The lubricant is Clariant wax powder PE520; The coupling agent is a silane coupling agent; The antioxidant is BASF antioxidant 168;

[0040] (2) Mix GPPS, K glue and SMA in a high mixer, then add toughening agent, lubricant, coupling agent and antioxidant, and mix well;

[0041] (3) A twin-screw extruder is used for melt extrusion and granulation.

[0042] Through detection and calculation, the light transmittance of the transparent impact-resistant polystyrene of the present invention is 93.3%.

Embodiment 2

[0044] (1) Prepare raw materials according to the following percentages by weight:

[0045] GPPS32%, K glue 62%, SMA0.5%, toughening agent 5%, lubricant 0.2%, coupling agent 0.15%, antioxidant 0.15%;

[0046] The GPPS is GP5500 of Taihua; the K glue is KR-03 of Chevron; the SMA is SMA-700 of Shanghai Huawen Electronic New Material Co., Ltd.; the toughening agent is 3540 produced by Taiwan Li Changrong The lubricant is Clariant wax powder PE520; the coupling agent is a silane coupling agent; the antioxidant is BASF antioxidant 168;

[0047] (2) Mix GPPS, K glue and SMA in a high mixer, then add toughening agent, lubricant, coupling agent and antioxidant, and mix well;

[0048] (3) A twin-screw extruder is used for melt extrusion and granulation.

[0049] Through detection and calculation, the light transmittance of the transparent impact-resistant polystyrene of the present invention is 95.1%.

Embodiment 3

[0051] (1) Prepare raw materials according to the following percentages by weight:

[0052] GPPS36%, K glue 57%, SMA0.5%, toughening agent 6%, lubricant 0.25%, coupling agent 0.15%, antioxidant 0.1%;

[0053]The GPPS is GP150 of Kumho, Korea; the K glue is KR-05 of Chevron; the SMA is SMA-700 of Shanghai Huawen Electronic New Material Co., Ltd.; the toughening agent is Taiwan Rubber 6150; The lubricant is Honeywell6A wax; The coupling agent is a titanate coupling agent; The antioxidant is BASF antioxidant 1010;

[0054] (2) Mix GPPS, K glue and SMA in a high mixer, then add toughening agent, lubricant, coupling agent and antioxidant, and mix well;

[0055] (3) A twin-screw extruder is used for melt extrusion and granulation.

[0056] Through detection and calculation, the light transmittance of the transparent impact-resistant polystyrene of the present invention is 93.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com