A kind of PLA modified material and its manufacture method

A technology for modifying materials and raw materials, applied in the chemical industry, can solve the problems of casting polylactic acid film technology and immature equipment, and achieve the effects of improving toughness, reducing brittleness, and good heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

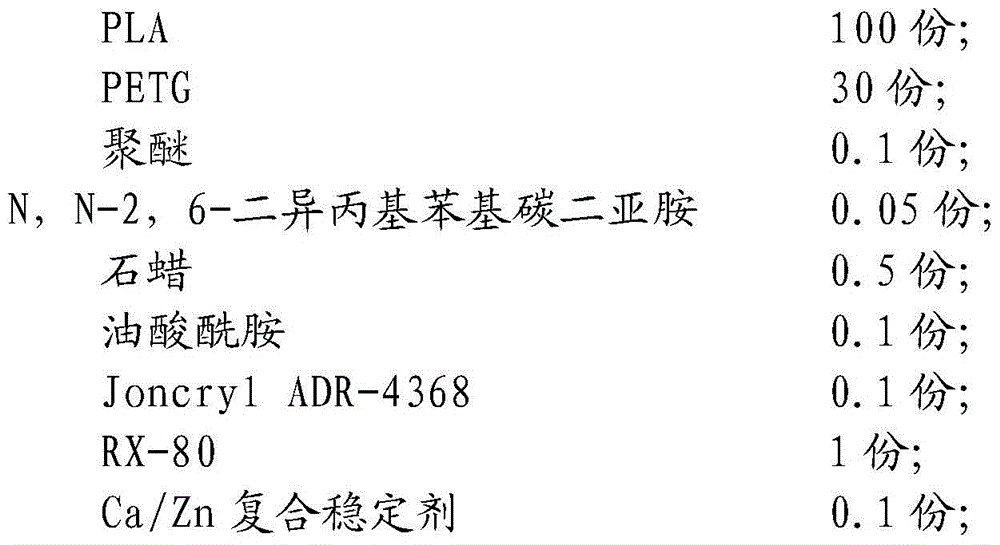

[0047] PLA modified material 1#, formula components:

[0048]

[0049] PLAJoncryl ADR-4368 resin and polyester are block-polymerized through twin-screws, and components such as flexible chain molecules are introduced during the manufacturing process.

Embodiment 2

[0051] PLA modified material 2#, formula components:

[0052]

[0053]

[0054] The PLA resin and polyester are block-polymerized through twin-screws, and components such as flexible chain molecules are introduced during the manufacturing process.

Embodiment 3

[0056] PLA modified material 3#, formula components:

[0057]

[0058] The PLA resin and polyester are block-polymerized through twin-screws, and components such as flexible chain molecules are introduced during the manufacturing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com