Process for extracting squalene by complex

A squalene and complexing technology, applied in the field of separation and purification of biologically active substances, can solve problems such as no research reports, and achieve the effects of easy dissociation and separation, realization of regeneration, and high efficiency and selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

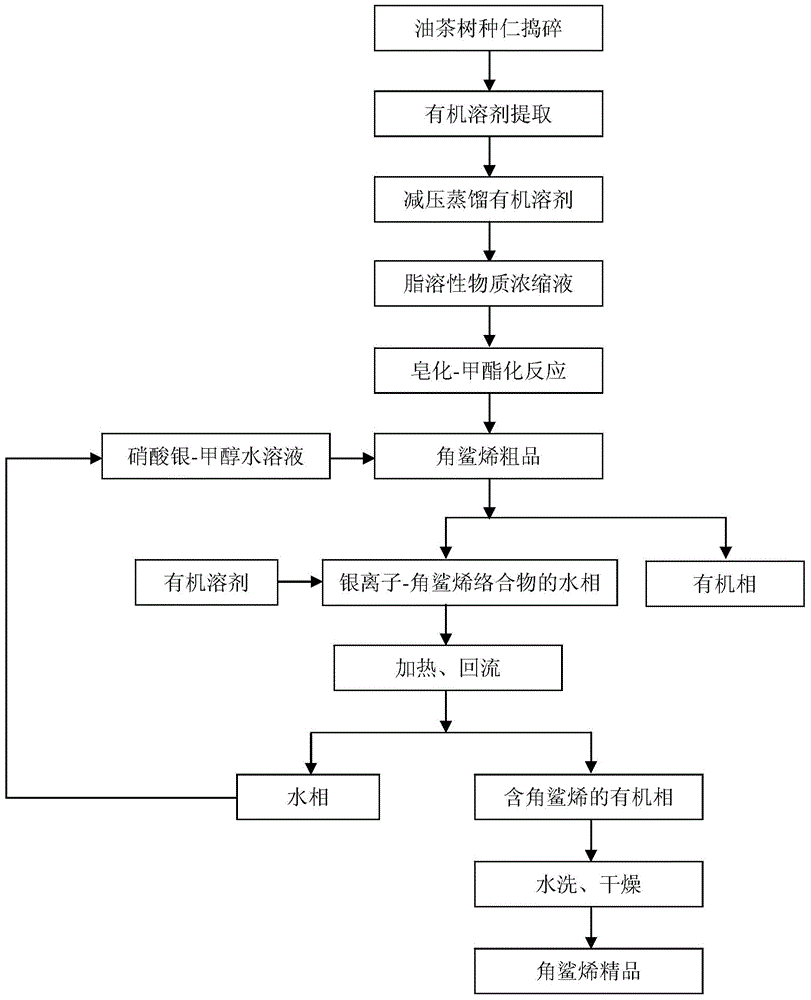

Image

Examples

Embodiment 1

[0028] A kind of technique for extracting squalene by complexation, the method comprises the steps:

[0029] (1) Preparation: wash 1 kg of fresh camellia seed kernels with clean water to remove the dirt attached to the surface, peel and break the shells; mix the resultant with petroleum ether in a mass ratio of 1:5 and ultrasonically (160W, 30min, 3 times) , combined extracts, filtered, concentrated under reduced pressure to obtain Camellia oil-soluble substance concentrated solution (wherein squalene content 10g / L);

[0030] (2) Extraction: Mix the concentrated solution of camellia oil-soluble substances obtained in step (1) with methanol solution of sodium hydroxide, heat in a water bath at 50°C, stir and reflux for 2 hours, wherein the concentration of sodium hydroxide is 0.7mol / L, and the concentration of camellia oil-soluble The volume ratio of the substance concentrate to the methanol solution of sodium hydroxide is 1:20, the fatty acid is removed through saponification ...

Embodiment 2

[0035] A kind of technique for extracting squalene by complexation, the method comprises the steps:

[0036] (1) Preparation: Wash 1 kg of fresh camellia seed kernels with clean water to remove the dirt attached to the surface, peel and break the shells; mix the resultant with petroleum ether in a mass ratio of 1:5 and ultrasonically (200W, 50min, 3 times) , combined extracts, filtered, concentrated under reduced pressure to obtain Camellia oil-soluble substance concentrated solution (wherein squalene content 9g / L);

[0037](2) Extraction: Mix the concentrated solution of camellia oil-soluble substances obtained in step (1) with methanol solution of sodium hydroxide, heat in a water bath at 70°C, stir and reflux for 4 hours, wherein the concentration of sodium hydroxide is 0.9mol / L, and the concentration of camellia oil-soluble The volume ratio of the substance concentrate to the methanol solution of sodium hydroxide is 1:50, the fatty acid is removed through saponification an...

Embodiment 3

[0042] A kind of technique for extracting squalene by complexation, the method comprises the steps:

[0043] (1) Preparation: Wash 1kg of fresh camellia seed kernels with clean water to remove the dirt attached to the surface, peel and break the shells; mix the resultant with n-hexane in a mass ratio of 1:5 and ultrasonically (60W, 20min, 3 times) , combined extracts, filtered, concentrated under reduced pressure to obtain Camellia oil-soluble substance concentrated solution (wherein squalene content 8g / L);

[0044] (2) Extraction: Mix the concentrated solution of camellia oil-soluble substances obtained in step (1) with methanol solution of sodium hydroxide, heat in a water bath at 30°C, stir and reflux for 1h, wherein the concentration of sodium hydroxide is 0.4mol / L, and the concentration of camellia oil-soluble The volume ratio of the substance concentrate to the methanol solution of sodium hydroxide is 1:10, the fatty acid is removed by saponification and methyl esterific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com