A kind of bamboo wood composite material

A composite material and composite board technology, used in wood processing appliances, wood veneer bonding, manufacturing tools, etc., can solve problems such as large damage to forest resources, poor elasticity of wood plywood, and difficulty in nailing, and improve the ecological environment. Quality, avoid warping deformation, easy nailing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention is described in detail as follows by several embodiments:

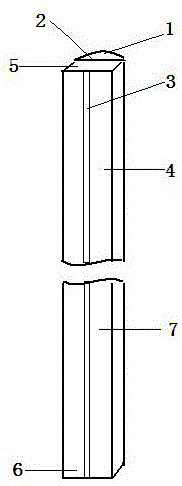

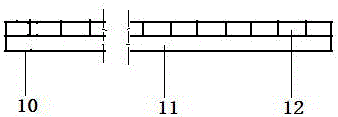

[0037] exist figure 1 Middle: This kind of bamboo-wood composite material includes Nanzhu. The outer skin of the bamboo tube is commonly called green skin 1, the surface close to the green skin 1 is called the back side 2, the inner skin of the bamboo tube is commonly called yellow skin 3, and the side close to the yellow skin 3 is called the front side 4 , the upper end of the growing bamboo is the head 5, and the lower end is the tail 6. The green skin 1 and the yellow skin 3 are removed from the bamboo material, and the area of the reserved part does not exceed 10% of the entire area. 7. Weave fine standard bamboo chips 7 into bamboo curtain 8 with thin thread rope 15. Bamboo curtain 8 is dried and has a moisture content of less than 12%. Press-in gluing is carried out, and wood chips 9 after rotary cutting are dried to make them contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com