An electrode for suppressing cracks in aluminum alloy resistance spot welding

A resistance spot welding, aluminum alloy technology, applied in resistance welding equipment, electrode features, welding medium, etc., can solve the problems of weakening lift-off deformation, reducing the number of cracks, plastic deformation, etc., to suppress edge cracks and plate lift-off The effect of reduction, material deformation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

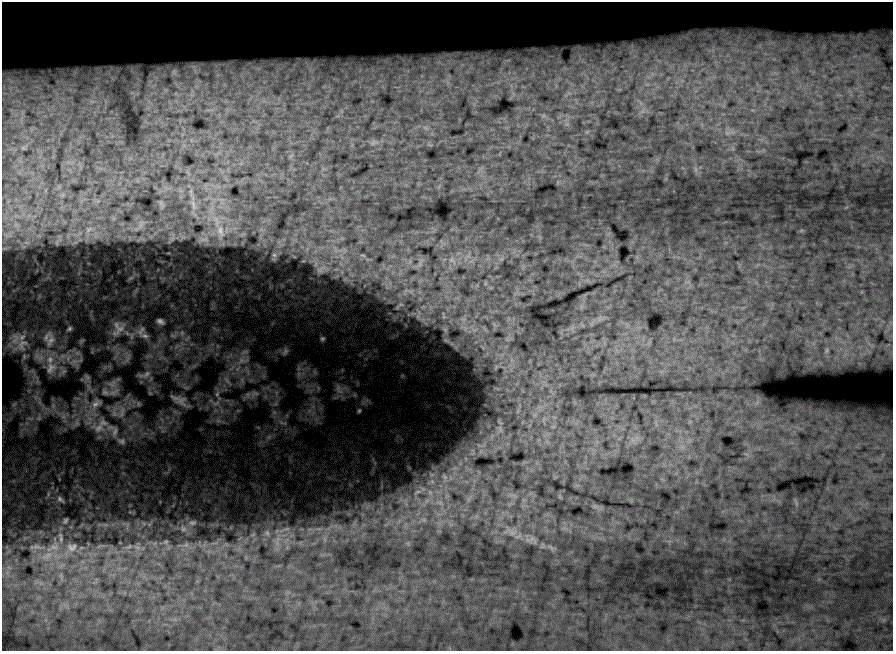

[0031] An electrode used to suppress cracks in aluminum alloy resistance spot welding, the electrode end face of the electrode is a straight end face, and the electrode end face has an outer circular groove and a central circular groove. The diameter of the spot welding electrode is 16mm, the diameter of the straight end surface is 6mm, and the radius of the transition arc surface is 8mm. There is an annular groove with a depth of 150um, a width of 0.41mm, and an inner chamfer of 45° at a position 2.2mm away from the axis on the straight end surface. There is a circular groove with a depth of 150um within 0.75mm from the axis.

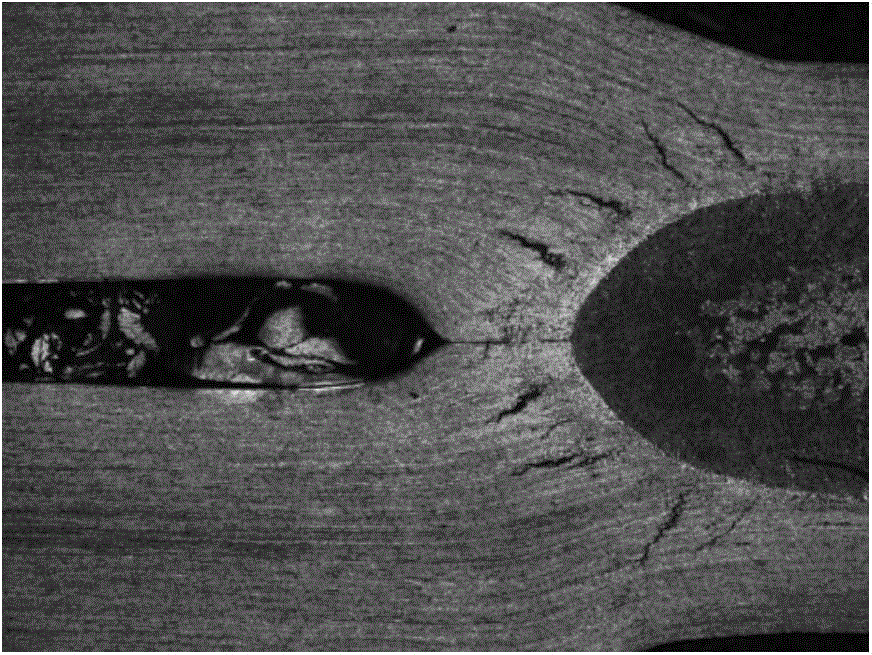

[0032]During spot welding, the upper and lower electrode end faces contact the surface of the aluminum plate, resulting in a small indentation. At this time, the spot welding process begins. With the increase of heat input, the material begins to form a nugget, the metal in the heat-affected zone begins to soften, and the edge of the electrode begins t...

Embodiment 2

[0034] Same as Example 1, the difference is that when the depth of the annular groove and the circular groove is 200um, the nugget indentation is deeper, the welding quality is better, and no crack occurs.

Embodiment 3

[0036] Same as Example 1, the difference is that when the depth of the annular groove and the circular groove is 100um, the nugget indentation is shallower, the welding quality is better, and no crack occurs.

[0037] Table 1 shows the comparison of tensile and shear strength using single pulse and multi-pulse + modified electrodes.

[0038] Table 1 Comparison of tensile and shear strength (unit N)

[0039]

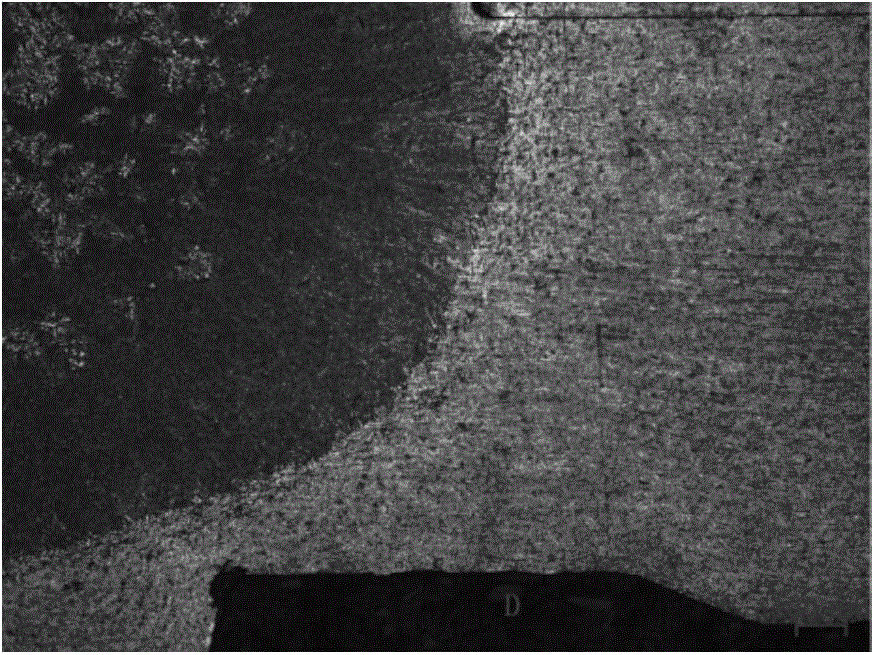

[0040] As shown in Table 1, the single-pulse maximum tensile-shear strength value reaches 3790N, but the distribution is not stable enough; in the combination of multi-pulse and modified electrodes, the average tensile-shear strength value reaches 3733N, and the distribution is very stable. The existence of annular indentation makes the current density more uniform, the nugget becomes fuller, and reduces the local breakdown, pitting, splashing and other defects that are easy to occur on flat end electrodes, and more importantly, eliminates cracks in the heat-affected z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com