A kind of production improvement method of Nocardia rubrum skeleton emulsion

A technology of Nocardia rubrum and emulsion, which is applied in the field of production improvement of Nocardia rubrum skeleton emulsion, can solve the problems of poor emulsification effect stability, difficult to achieve sterilization and filtration, and impurities containing titanium powder, etc., and achieve improvement Sterilization and filtration effect, improvement of efficiency and processing scale, effect of reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

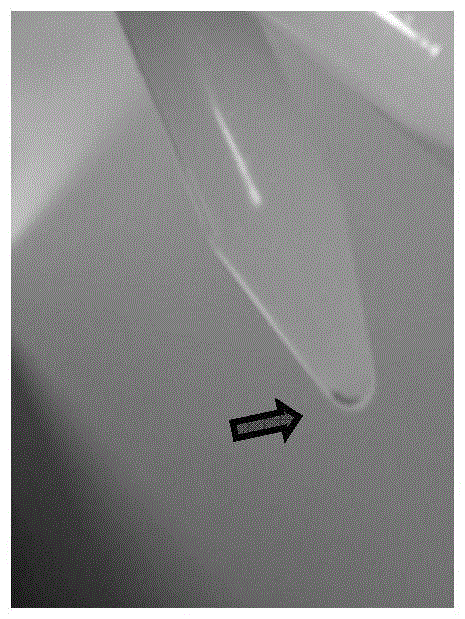

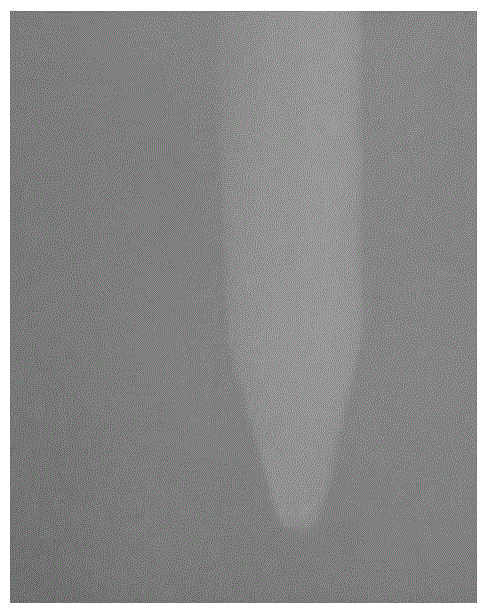

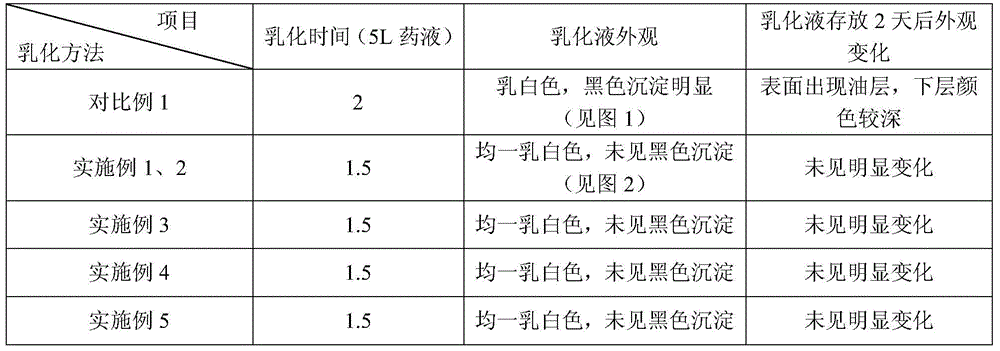

Examples

Embodiment 1

[0049] 1. The original powder of the cell wall skeleton of Nocardia rubrum and auxiliary materials are accurately weighed and prepared according to the prescription amount (the prescription is the same as that of Comparative Example 1).

[0050] 2. Deepen the dispersing head of the high-speed shearing machine into the liquid medicine to about 1-2cm to the bottom, and turn on the power for shearing and dispersing. Adjust the rotating speed to 17000rpm, and cut for 20min.

[0051] 3. After shearing, transfer the medicinal solution to the sampling cup of the high-pressure homogenizer, and turn on the high-pressure homogenizer for homogenization. The working pressure is 1500bar.

[0052] 4. Collect the homogenized drug solution and perform the second homogenization.

[0053] 5. After the drug solution is homogenized twice, a uniform emulsion is obtained. Transfer the emulsion to a filtration system for filtration. The pore size of the filter element is 0.22 μm.

Embodiment 2

[0055] 1. The original powder of the cell wall skeleton of Nocardia rubrum and auxiliary materials are accurately weighed and prepared according to the prescription amount (the prescription is the same as that of Comparative Example 1).

[0056] 2. Deepen the dispersing head of the high-speed shearing machine into the liquid medicine to about 1-2cm to the bottom, and turn on the power for shearing and dispersing. Adjust the rotating speed to 17000rpm, and cut for 20min.

[0057] 3. After shearing, transfer the medicinal solution to the sampling cup of the high-pressure homogenizer, and turn on the high-pressure homogenizer for homogenization. The working pressure is 1500bar.

[0058] 4. Collect the homogenized drug solution and perform the second homogenization.

[0059] 5. After the drug solution is homogenized twice, a uniform emulsion is obtained. Transfer the emulsion to a filtration system for filtration. The pore size of the filter element used in the first filtration...

Embodiment 3

[0061] 1. The original powder of the cell wall skeleton of Nocardia rubrum and auxiliary materials are accurately weighed and prepared according to the prescription amount (the prescription is the same as that of Comparative Example 1).

[0062] 2. Deepen the dispersing head of the high-speed shearing machine into the liquid medicine to about 1-2cm to the bottom, and turn on the power for shearing and dispersing. Adjust the rotating speed to 15000rpm, and cut for 20min.

[0063] 3. After shearing, transfer the medicinal solution to the sampling cup of the high-pressure homogenizer, and turn on the high-pressure homogenizer for homogenization. The working pressure is 1500bar.

[0064] 4. Collect the homogenized drug solution and perform the second homogenization.

[0065] 5. After the drug solution is homogenized twice, a uniform emulsion is obtained. Transfer the emulsion to a filtration system for filtration. The pore size of the filter element used in the first filtration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com