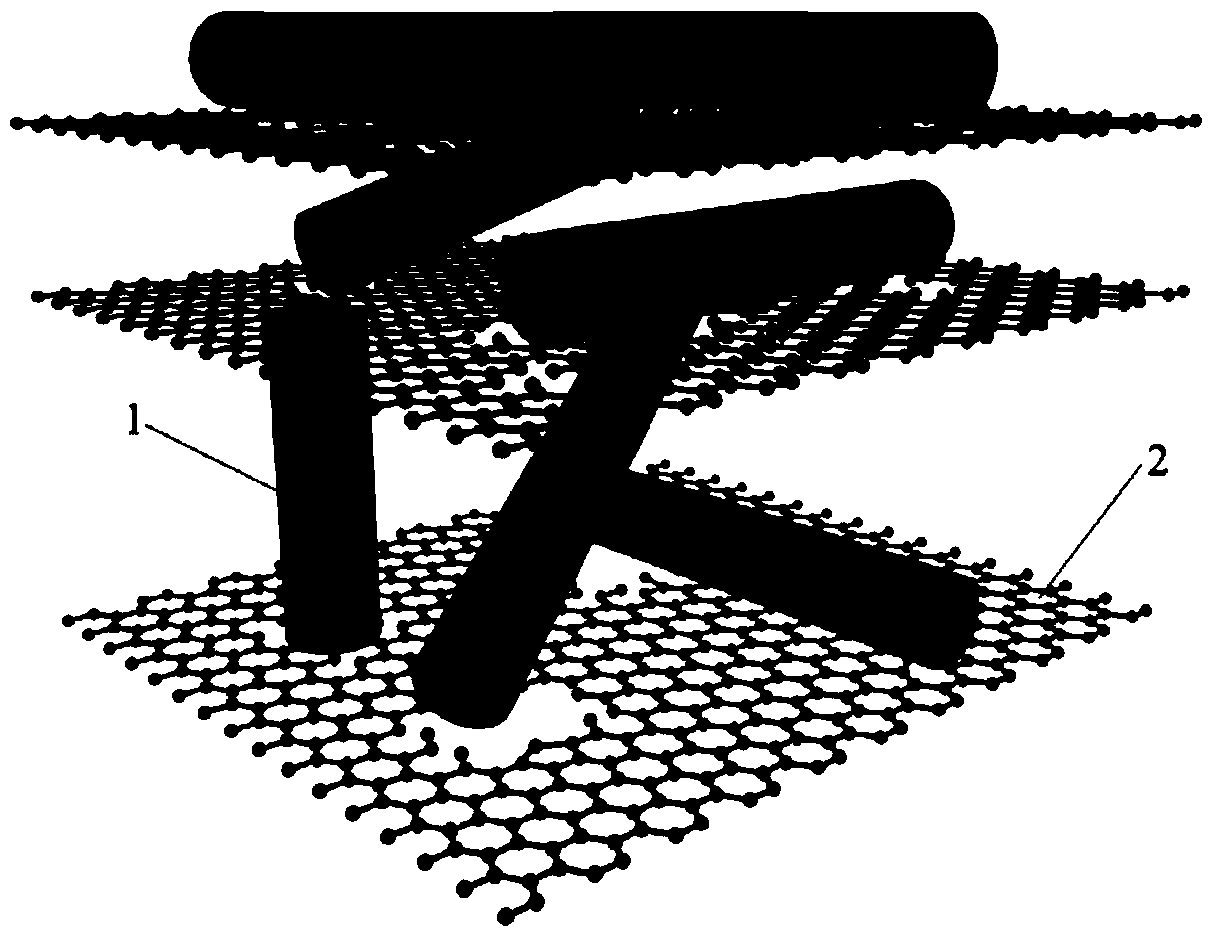

Flexible electrode and preparation method thereof

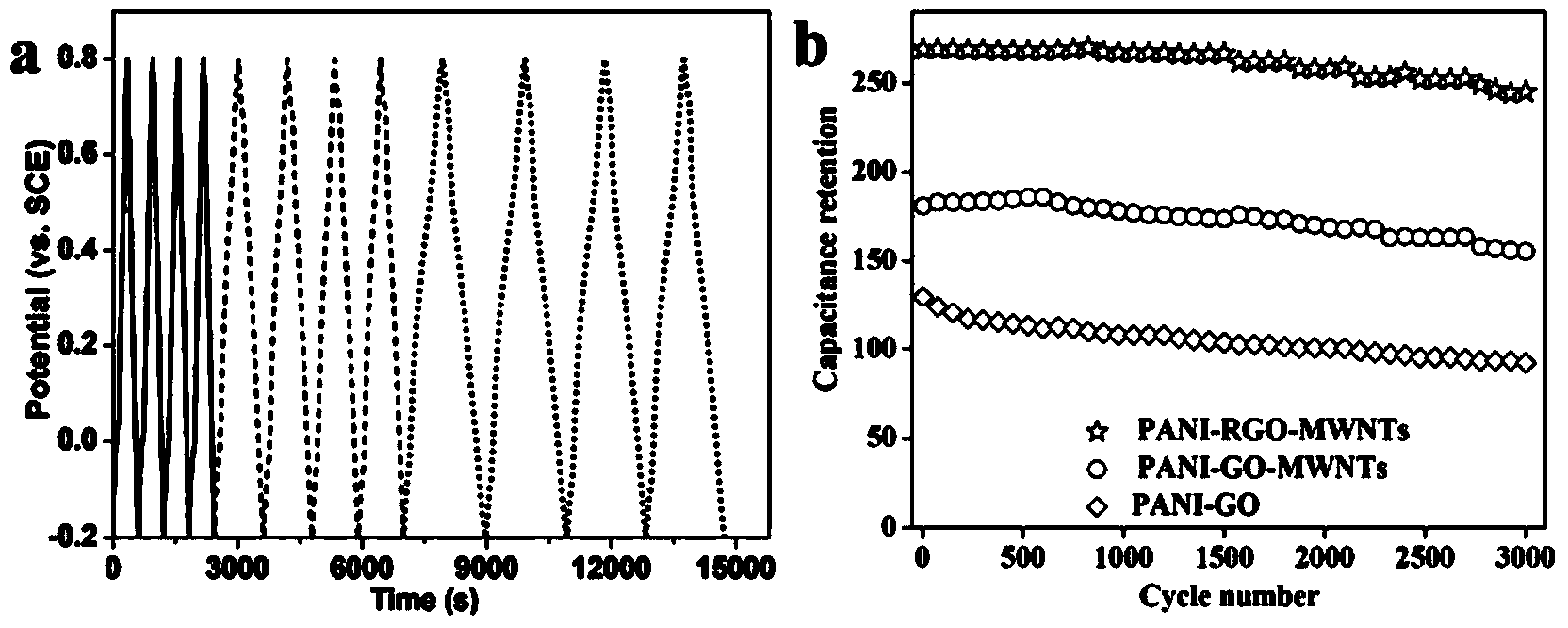

A flexible electrode and flexible technology, which is applied in the preparation of flexible electrodes and the field of flexible electrodes, can solve the problems of low electrochemical performance and small capacitance, and achieve the effects of increasing spacing and specific surface area, increasing unit capacitance, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The aniline that this example adopts is prepared by distillation under reduced pressure; Ammonium persulfate, graphite and carbon nanotubes are all purchased on the market, and wherein graphite is 325 orders, and carbon nanotube diameter 10-30nm, long 5-15 micron, purity >=95% ( weight); other reagents are commercially purchased analytical reagents without further processing.

[0029] The graphene oxide of this example is prepared by the Hummers method using purchased 325-mesh graphite as a raw material. The Hummers method is a relatively common method in the chemical stripping method, which is recorded in an article published by HummersWS: Hummers W S, Offeman R E. Preparation of graphitic oxide [J]. J Am Chem Soc, 1958, 80 (6) :1339. I won't repeat it here.

[0030] The flexible electrode preparation method in this example includes:

[0031] a. The preparation of carbon nanotube and graphene oxide mixed dispersion liquid, at first, disperse 50mg graphene oxide in d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com