Fur tanning agent based on isocyanate and preparation method of fur tanning agent

A technology of isocyanate and diisocyanate, applied in the field of isocyanate-based fur tanning agent and preparation thereof, can solve problems such as unfavorable storage of compounds, extra storage cost, etc., and achieve the effects of omitting synthesis steps, competitive advantages in a large market, and soft leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

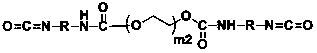

Method used

Image

Examples

Embodiment 1

[0038] 0.05 mol of polyethylene glycol (Mn=400) was dissolved in 80 mL of mixed toluene and ethyl acetate, then 0.11 mol of IPDI and 1-2 drops of dibutyltin dilaurate catalyst were added, and reacted at 40°C for 3 h. After the reaction was completed, the toluene and ethyl acetate solvents were evaporated by rotary evaporation under reduced pressure to obtain an intermediate product, which was dissolved in an ethanol solution. An aqueous solution of sodium bisulfite containing 0.11 mol was added to the ethanol solution, and the reaction was carried out at a constant temperature of 5° C. for 2 hours. Ethanol was removed by rotary evaporation again to obtain the aqueous solution of the target tanning agent product.

Embodiment 2

[0040] 0.05 mol of propylene glycol was dissolved in 80 mL of mixed acetone and toluene, then 0.11 mol of MDI and 1-2 drops of dibutyltin dilaurate catalyst were added, and the reaction was carried out at 40°C for 3 h. After the reaction was completed, the acetone and toluene solvents were evaporated by rotary evaporation under reduced pressure to obtain an intermediate product, which was dissolved in ethanol solution. An aqueous solution of sodium bisulfite containing 0.11 mol was added to the ethanol solution, and the reaction was carried out at a constant temperature of 5° C. for 2 hours. Ethanol was removed by rotary evaporation again to obtain the aqueous solution of the target tanning agent product.

Embodiment 3

[0042] 0.05 mol polyethylene glycol (Mn=1000) was dissolved in 80 mL tetrahydrofuran solvent, then 0.11 mol HDI and 1-2 drops of dibutyltin dilaurate catalyst were added, and reacted at 40 °C for 3 h. After the reaction was completed, the tetrahydrofuran solvent was evaporated by rotary evaporation under reduced pressure to obtain an intermediate product, which was dissolved in ethanol solution. An aqueous solution of potassium bisulfite containing 0.11 mol was added to the ethanol solution, and the reaction was carried out at a constant temperature of 5° C. for 2 hours. Ethanol was removed by rotary evaporation again to obtain the aqueous solution of the target tanning agent product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com