An antibacterial polylactic acid composite material and a preparing method thereof

A composite material, polylactic acid technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of limited PLA application and poor toughness, and achieve photocatalytic activity, good mechanical properties, and high antibacterial properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Surface treatment of modified titanium dioxide:

[0033] Put 1 part of modified titanium dioxide with a particle size of 15-50nm in a two-dimensional mixer and stir; mix 0.2 part of 3-aminopropyltriethoxysilane (KH550) with 0.2 part of stearic acid, spray Put it into the mixer to modify the surface of titanium dioxide, continue to stir for 5 to 15 minutes after spraying, and set aside;

[0034] (2) Mix the raw materials evenly: put the modified titanium dioxide treated in step (1), 100 parts of polylactic acid, 10 parts of PEG and 0.3 parts of tris(2,4-di-tert-butylphenyl) phosphite in the mixer well mixed;

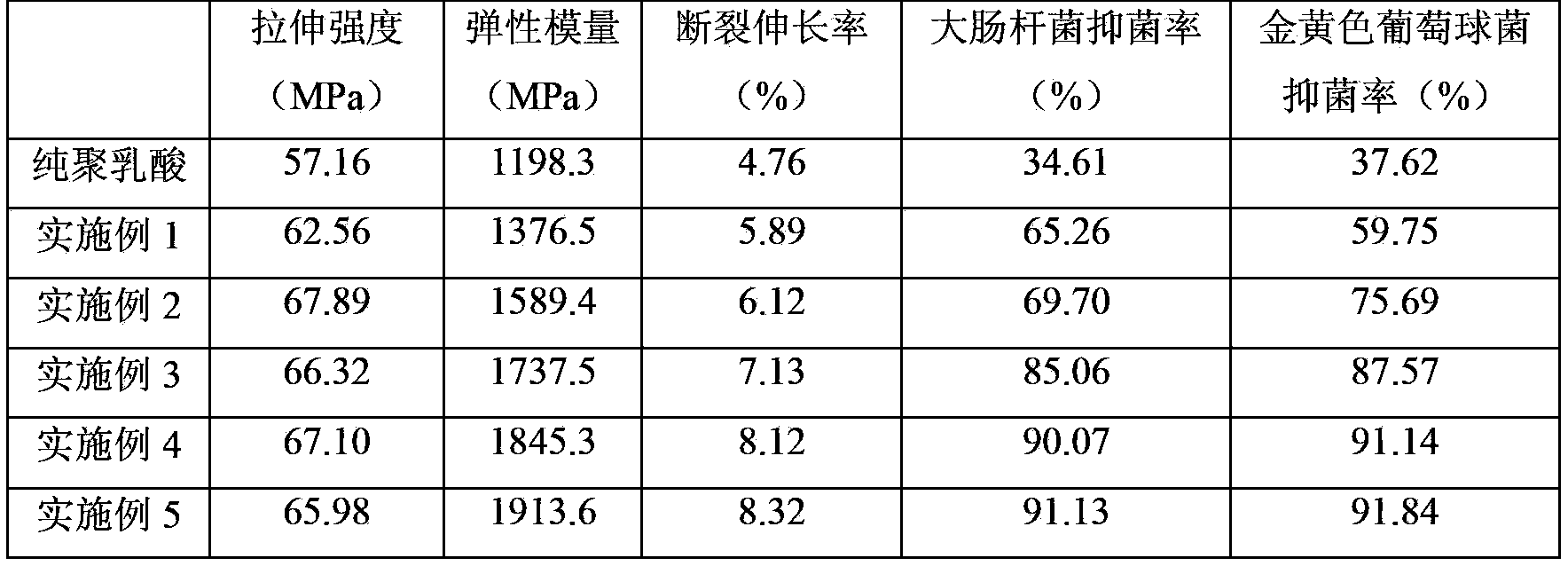

[0035] (3) Mixing in a twin-screw extruder: Mix the raw materials uniformly mixed in the above step (2) with a twin-screw extruder, the extrusion temperature is 150°C in the low area, 210°C at the die head, and 150°C in the middle section °C to 210 °C, the screw speed is set to 50 rpm. The polylactic acid composite material was obtained, and its properties a...

Embodiment 2

[0037] (1) Surface treatment of modified titanium dioxide:

[0038] Put 2 parts of modified titanium dioxide with a particle size of 15-50nm in a two-dimensional mixer and stir; mix 0.3 part of γ-(methacryloyloxy)propyltrimethoxysilane (KH570) with 0.3 part of calcium stearate After uniformity, spray it into the surface of the modified titanium dioxide in the mixer, continue to stir for 5-15 minutes after spraying, and set aside;

[0039] (2) Mix the raw materials evenly: put the modified titanium dioxide treated in step (1), 100 parts of polylactic acid, 15 parts of PEG and 0.5 part of phosphite tris(2,4-di-tert-butylphenyl) in the mixer mix evenly;

[0040] (3) Mixing in a twin-screw extruder: Mix the raw materials uniformly mixed in the above step (2) with a twin-screw extruder, the extrusion temperature is 150°C in the low area, 210°C at the die head, and 150°C in the middle section ℃~210℃, the screw speed was set at 60rpm, and the polylactic acid composite material was ...

Embodiment 3

[0042] (1) Surface treatment of modified titanium dioxide:

[0043] Put 2.5 parts of modified titanium dioxide with a particle size of 15-50nm in a two-dimensional mixer and stir; mix 0.5 parts of 3-aminopropyltriethoxysilane (KH550) with 0.5 parts of zinc stearate evenly, and spray Spray into the surface of the modified titanium dioxide in the mixer, continue to stir for 5 to 15 minutes after spraying, and set aside;

[0044] (2) Mix the raw materials evenly: Mix the modified titanium dioxide treated in step (1), 100 parts of polylactic acid, 20 parts of PEG and 0.7 parts of phenylene diisodecyl phosphite in a mixer;

[0045] (3) Mixing in a twin-screw extruder: Mix the raw materials uniformly mixed in the above step (2) with a twin-screw extruder, the extrusion temperature is 150°C in the low area, 210°C at the die head, and 150°C in the middle section ℃~210℃, the screw speed was set at 60rpm, and the polylactic acid composite material was prepared, and its properties are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com