Preparation method of high-strength chrome-free brick for steel-making RH (Ruhstahl Hausen) vacuum refining slot

A technology for vacuum refining and chrome bricks is applied in the field of refractory materials for steelmaking RH vacuum refining tanks, which can solve the problems affecting the effective application of chrome-free bricks, poor corrosion resistance, and easy powdering and fracture, so as to enhance corrosion resistance. and thermal shock performance, make up for poor corrosion resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the high-strength chrome-free brick, the steps are as follows;

[0041] 1) Make composite additives, which are made of the following ingredients in proportion by weight: 0-2 parts of boron nitride powder, 0-2 parts of ferrosilicon nitride; accurately weigh the above raw materials according to the weight ratio, and put them into the stirring Grinding and co-grinding, stirring for 10-15 minutes, closed for use;

[0042] 2) Make a composite binder, which is made of the following ingredients in proportion by weight: 2.5-5 parts of pulp waste liquid, 1-2 parts of sodium lignosulfonate powder; accurately weigh the above raw materials according to the weight ratio, put Stir in a mixing bucket for 10-15 minutes, close and set aside;

[0043] 3) First put 6-1mm low-silicon fused magnesia, 1-0.088mm low-silicon fused magnesia and / or fused magnesia-aluminum spinel and zirconia fiber into the high-speed In the kneader, mix for 2-6 minutes at a time; add ...

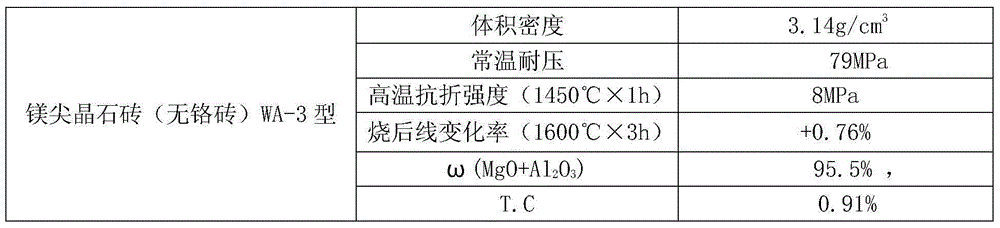

Embodiment 1

[0051] [Example 1] Preparation of a chrome-free brick with excellent corrosion resistance

[0052] 1) Making composite additives, made of the following ingredients in proportions by weight: 0.85 parts of boron nitride powder, 1.15 parts of ferrosilicon nitride; the raw materials were accurately weighed according to the proportions by weight, and put into a stirring mill for a total Grind and stir for 10 minutes, seal and set aside;

[0053] 2) Make a composite binder, which is made of the following components in parts by weight: 3.1 parts of pulp waste liquid, 0.9 parts of sodium lignosulfonate powder; accurately weigh the raw materials according to the parts by weight, and put them into agitation Stir in the bucket for 12 minutes, close it for use;

[0054] 3) First, 35 parts of 6-1mm low-silicon fused magnesia, 15 parts of 1-0.088mm low-silicon fused magnesia, 10 parts of 1-0.088mm fused magnesia-aluminum spinel according to the weight ratio 1 part of zirconia fiber, put i...

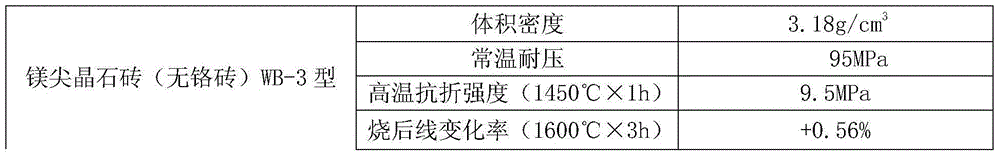

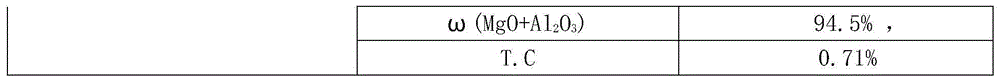

Embodiment 2

[0057] [Example 2] Preparation of a high-strength chrome-free brick

[0058] 1) Making composite additives, made of the following ingredients in proportions by weight: 0.75 parts of boron nitride powder, 1.25 parts of ferrosilicon nitride; the raw materials were accurately weighed according to the proportions by weight, and put into a stirring mill for a total Grind and stir for 12 minutes, seal and set aside;

[0059] 2) Make a composite binder, which is made of the following ingredients in proportion by weight: 3.2 parts of pulp waste liquid, 1 part of sodium lignosulfonate powder; accurately weigh the raw materials according to the proportion by weight, and put them into agitation Stir in the barrel for 15 minutes, close it for use;

[0060] 3) First, 35 parts of 6-1mm low-silicon fused magnesia, 15 parts of 1-0.088mm low-silicon fused magnesia, 10 parts of 1-0.088mm fused magnesia-aluminum spinel according to the weight ratio Parts, 1.5 parts of zirconia fiber, put into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com