Method for preparing bismuth oxychloride

A technology of bismuth oxychloride and bismuth salt, which is applied in the field of preparation of bismuth oxychloride, can solve the problems of uncontrollable, small size of bismuth oxychloride, difficult to meet the requirements of the application field, etc., and achieves the effect of size controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of bismuth oxychloride crystal, comprises the following steps:

[0035] Under the action of the non-ionic surfactant, the bismuth salt mixed solution reacts under the condition of constant pH value to obtain bismuth oxychloride crystals; the bismuth salt mixed solution includes bismuth ions, chloride ions, nitrate ions and water.

[0036] The present invention makes the bismuth salt mixed solution comprising bismuth ion, chloride ion, nitrate ion and water react under the effect of constant pH value under the effect of nonionic surfactant, by adjusting constant pH value and selecting appropriate nonionic surfactant The ionic surfactant makes the formation speed, shape and size of bismuth oxychloride crystals controllable, thereby preparing micron-level bismuth oxychloride, and its size is controllable.

[0037] All the raw materials of the present invention have no special limitation on their sources, they can be purch...

Embodiment 1

[0059] Bismuth chloride was dissolved in nitric acid to prepare a bismuth salt mixed solution with a bismuth ion concentration of 2.0 mol / L.

[0060] In a 5L reaction vessel, add 1.5L deionized water, start stirring and add hydrochloric acid, adjust the pH to 0.1, heat the above mixed solution to 75°C, add 1g of OP emulsifier with a molecular weight of 646, and , add the above-mentioned bismuth salt mixed solution dropwise to the mixed solution with OP emulsifier at a rate of 0.06ml / min, and at the same time slowly add 6mol / L NaOH solution to keep the pH value at 0.1. After 10 hours, stop adding the bismuth salt and mix solution, continue to add NaOH solution until the pH value of the reaction mixture is 8.0, stop heating and stirring, drop to room temperature, wash and filter with distilled water to obtain bismuth oxychloride.

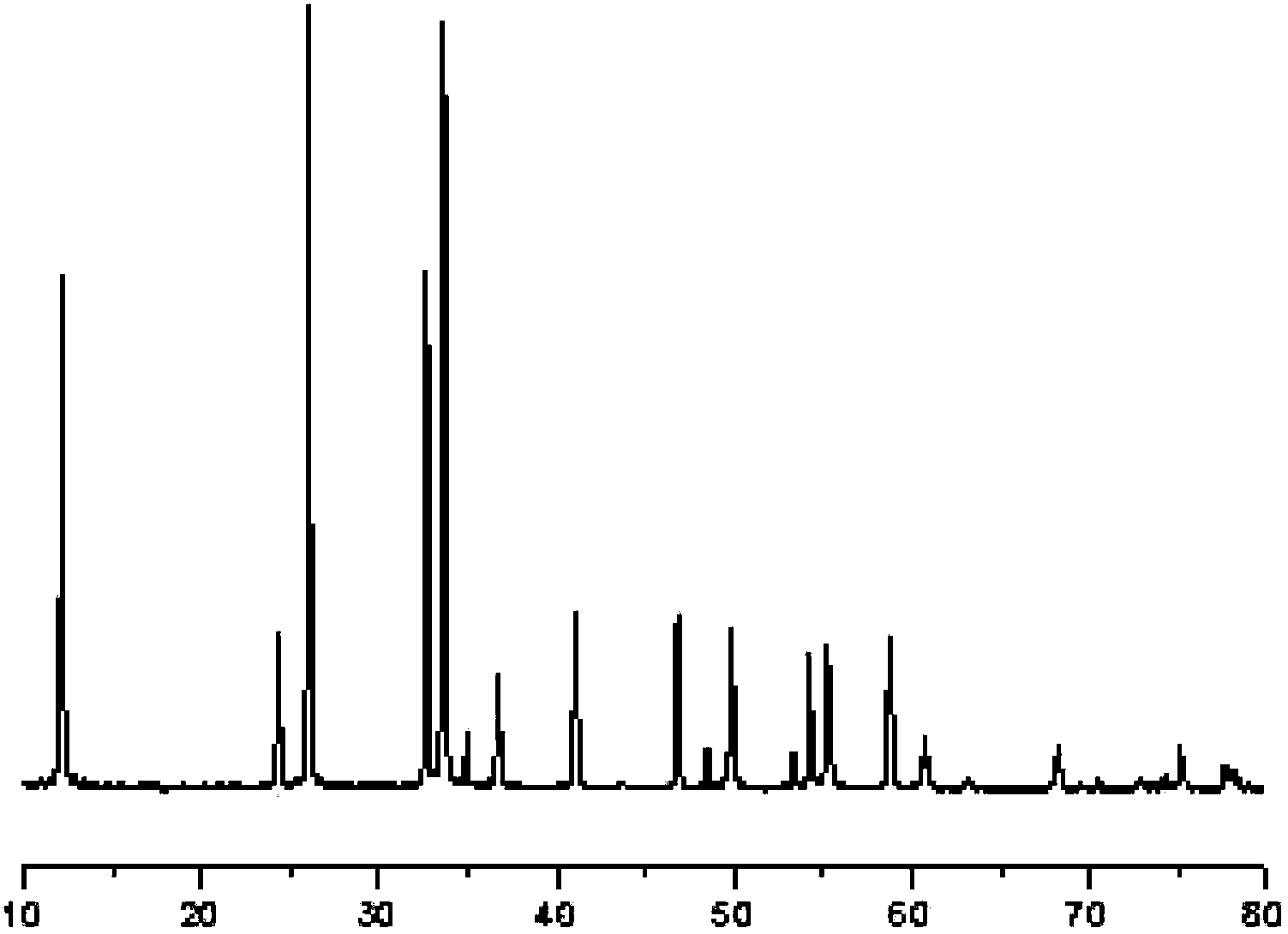

[0061] Bismuth oxychloride was observed by scanning electron microscope, the results can be found in figure 1 , figure 1 It is the bismuth oxychlor...

Embodiment 2

[0064] Bismuth chloride was dissolved in nitric acid to prepare a bismuth salt mixed solution with a bismuth ion concentration of 2.2 mol / L.

[0065] In a 5L reaction vessel, add 1.5L deionized water, start stirring and add hydrochloric acid, adjust the pH value to 2.0, heat the above mixed solution to 85°C, add 0.5g Tween 80, and add Add the above-mentioned bismuth salt mixed solution dropwise in the mixed solution of Tween 80, the dropping rate is 0.03ml / min, and slowly add 6mol / L NaOH solution at the same time to keep the pH value at 2.0. After 11 hours, stop adding the bismuth salt mixed solution, continue Add NaOH solution until the pH value of the reaction mixture is 9.0, stop heating and stirring, cool down to room temperature, wash and filter with distilled water to obtain bismuth oxychloride crystals.

[0066] Bismuth oxychloride was observed by scanning electron microscope, the results can be found in image 3 , image 3 Be the bismuth oxychloride scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com