Preparation method for pollution-resistant polymer membrane

A polymer membrane and anti-pollution technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex membrane forming process, difficult control of membrane pore size, high membrane preparation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

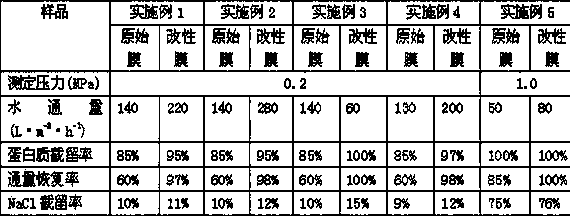

Examples

Embodiment 1

[0038] Pour 18 grams of phenolphthalein type polyaryletherketone (PEK-C) into a round bottom flask, then add 8 grams of polyethylene glycol (PEG-600) additive and 74 grams of N-methylpyrrolidone (NMP) solvent, at 50 Stir and dissolve rapidly at ℃ for 8 hours to obtain a uniform polymer solution; degas the polymer solution obtained above for 24 hours in vacuum at room temperature; slowly pour the obtained polymer solution on a clean glass plate, and adjust the scraping speed to 1.87 m / min, scrape out a film with a thickness of 150 microns (the thickness of the liquid layer), wait for 5 seconds in the air, then quickly put it into the deionized water coagulation bath, take it out after the film falls off automatically, and soak it in deionized water after cleaning Standby after 24 hours;

[0039]Add a layer of 2% (w / w) methanol solution of glycidyl methacrylate to the surface of the polyether ether ketone ultrafiltration membrane prepared by the phase inversion method. The surf...

Embodiment 2

[0043] Add a layer of 20% methanol solution of glycidyl methacrylate to the surface of the polyether ether ketone ketone film obtained in Example 1. After the surface of the film is infiltrated, place it in a 14 mW / cm2, wavelength of 380 nm Irradiate under ultraviolet light for 1.5 minutes to polymerize and graft glycidyl methacrylate on the surface of the membrane, and the modified membrane obtained is washed repeatedly with a mixture of methanol and water (2:1, v / v);

[0044] The modified membrane obtained in the previous step was immersed in a 35% concentrated hydrochloric acid solution to react for 2 hours. After the reaction, it was repeatedly washed with deionized water and methanol to obtain a membrane surface grafted with chloroalkane;

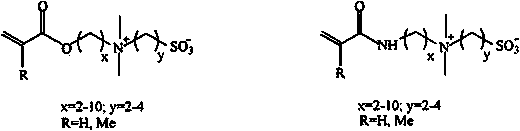

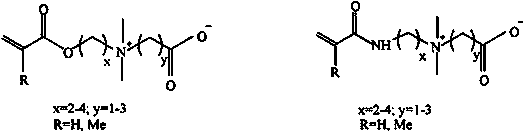

[0045] Add 10 milliliters of methanol and deionized water in a volume ratio of 1:1 mixed solution and a clean magnetic stirring rotor into a 50 milliliter polymerization tube, add 50 millimoles of phosphobetaine acrylate, and stir until...

Embodiment 3

[0047] Add a layer of 15% (w / w) methanol solution of glycidyl methacrylate to the surface of the polyether ketone ketone film obtained by the method of Example 1. After the film surface is soaked, place it at 15 mW / cm2 and Irradiate for 3 minutes under a 380-nanometer ultraviolet lamp to polymerize glycidyl methacrylate and graft it on the surface of the membrane. The modified membrane obtained is washed repeatedly with a mixture of methanol and water (2:1, v / v);

[0048] The modified membrane obtained in the previous step was immersed in a 48% (w / w) concentrated hydrobromic acid solution for 8 hours. After the reaction, it was washed repeatedly with deionized water and methanol to obtain a membrane grafted with bromoalkane surface;

[0049] Add 10 ml of methanol and deionized water in a volume ratio of 1:1 and a clean magnetic stirring rotor into a 50 ml polymerization tube, then add 1.5 mmol of copper bromide powder, 3 mmol of 2,2-bipyr and 100 mmol of acrylate sulfobetaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com