Heart-shaped heat exchange tube multi-tube high temperature hot blast furnace

A high-temperature hot blast stove and heat exchange tube technology, applied in the field of heat exchange, can solve the problems of air pollution, waste of heat energy loss, small heating area, etc., and achieve the effects of prolonging the walking distance and time, saving energy in smoke and dust emission, and improving heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

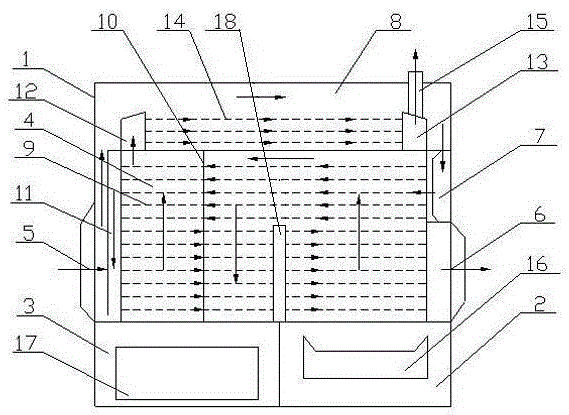

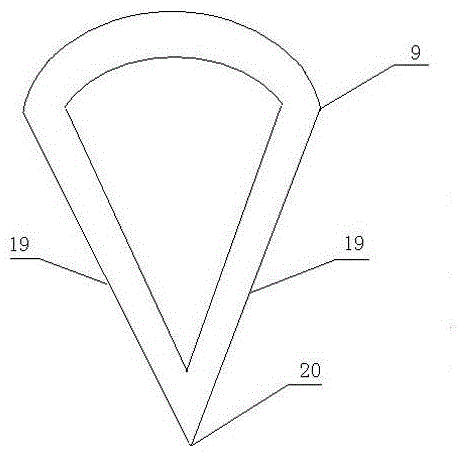

[0019] Example 1: Combustion chamber 2 converts biomass fuel into combustible gas. The combustible gas burns into a high-temperature flame in the environment of high temperature and open flame in combustion chamber 2. The flame enters heat exchange chamber 4 with smoke and dust, because across the The heat exchange tube 9 of the heat exchange chamber 4 is heart-shaped, and its heart-shaped tip 20 faces downward. The high-temperature flame first bakes the heart-shaped hypotenuse 19 of the heat exchange tube 9 in the lower part of the heat exchange chamber 4, and the heat passes through the heat exchange tube 9. The metal pipe wall of the heat pipe 9 passes into the heat exchange pipe 9, and the wind in the pipe is heated to make it become high-temperature hot air; wind. Because the heat exchange tube 9 is a multi-layer and multi-row dislocation design, the reserved flame passage is a circuitous passage and a narrow space. The heat exchange rate of the flame in the heat exchange...

Embodiment 2

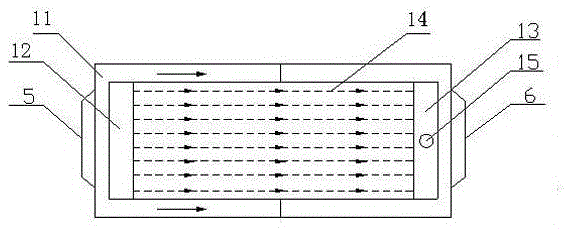

[0020] Embodiment 2: Of course, the flame that continues upward with smoke and dust completes the heat exchange in the heat exchange chamber 4, and enters the air chamber 11 with residual heat. After the dust settles in the air chamber 11, it enters the dust removal chamber 3, and the flue gas enters After the flue gas enters the chamber 12, it enters the flue gas outlet chamber 13 through the hot air pipe 14, and finally the flue gas is discharged from the exhaust pipe 15 connected to the flue gas outlet chamber 13.

Embodiment 3

[0021] Example 3: After dust is deposited in the air chamber 11 under the waste heat, it meets the cold wind entering from the air inlet 5 under the cold air outlet, and the waste heat in the first path is recovered; the flue gas also takes away part of the waste heat, and passes through the hot air pipe 14 The flue gas entering the flue gas outlet chamber 13 heats the hot air pipe 14, and when the cold air passes through the upper part of the waste heat return air passage 8 surrounding the combustion chamber 2, it exchanges heat with the hot air pipe 14, takes away the waste heat of the second path, and then enters The air inlet chamber 7 enters the heat exchange pipe 9 from the air inlet chamber 7, and pushes the hot air in the heat exchange pipe 9 to enter the air outlet 6, and the cold air continues to be heated by the high-temperature flame. After the high-temperature flue gas from the combustion chamber 2 enters the heat exchange chamber 4, it exchanges heat with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com