Mining air mist dust settling device in restricted space and application method of mining air mist dust settling device

A technology of limited space and dust reduction device, which is applied in the direction of safety devices, dust prevention, mining equipment, etc., to achieve the effect of less water consumption, less water consumption, and ensure the effect and efficiency of dust reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

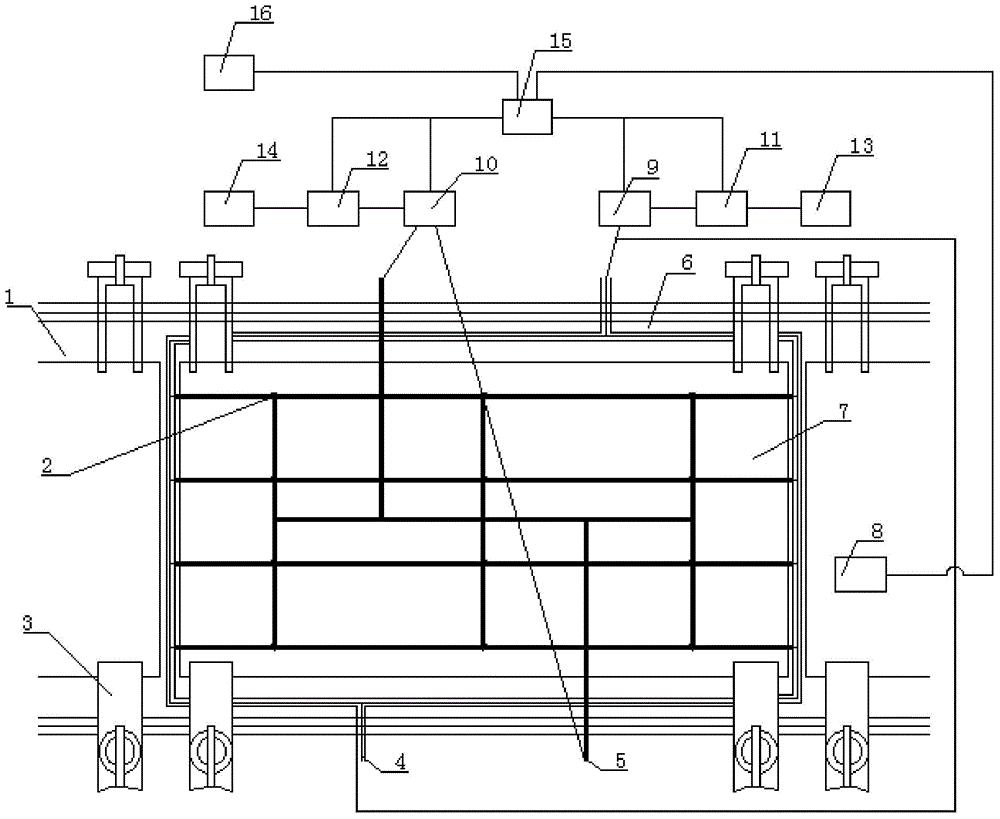

[0018]The device consists of a water inlet 4, an air inlet 5, a pipeline arranged in warp and weft, and a cover plate 7 composed of fiberglass or polyurethane light-weight wear-resistant, static-resistant, and flame-retardant materials, an atomizing dust removal nozzle 2, and a cover installation groove. 1. Sealing material in the tank 6. Cover plate fixing and pressing device 3. Dust sensor 8. Water volume adjustment device 9. Air volume adjustment device 10. Waterway control valve 11. Airway control valve 12. Water supply main waterway 13. Air supply total gas Road 14, intelligent controller 15, and transportation equipment start-stop signal 16; its water inlet 4 is not only the water supply network that distributes water for the entire dust suppression device, but also the water supply network is the main frame of the cover plate 7, which determines the cover plate. 7, and the air supply network represented by the air inlet 5, the latitude and longitude lines of the auxiliar...

Embodiment approach 2

[0026] Embodiment 2: The number of atomizing and dedusting nozzles 2 is 9, and the side water and air intake cover the top of the material conveying channel. The working space range of the nozzle 2 is 300 mm spray range; the air pipeline and the water pipeline constitute the cover The warp and weft of the board, and polyurethane lightweight wear-resistant and static-resistant materials are added to the empty part in the middle.

Embodiment approach 3

[0027] Embodiment 3: The number of atomizing and dedusting nozzles 2 is 6, and the side water and air intake cover the upper part of the material conveying channel. The working space range of the nozzle 2 is 350 mm spray range; the gas pipeline and the water pipeline constitute the cover The longitude and latitude of the board, and the flame-retardant material is added to the empty part in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com