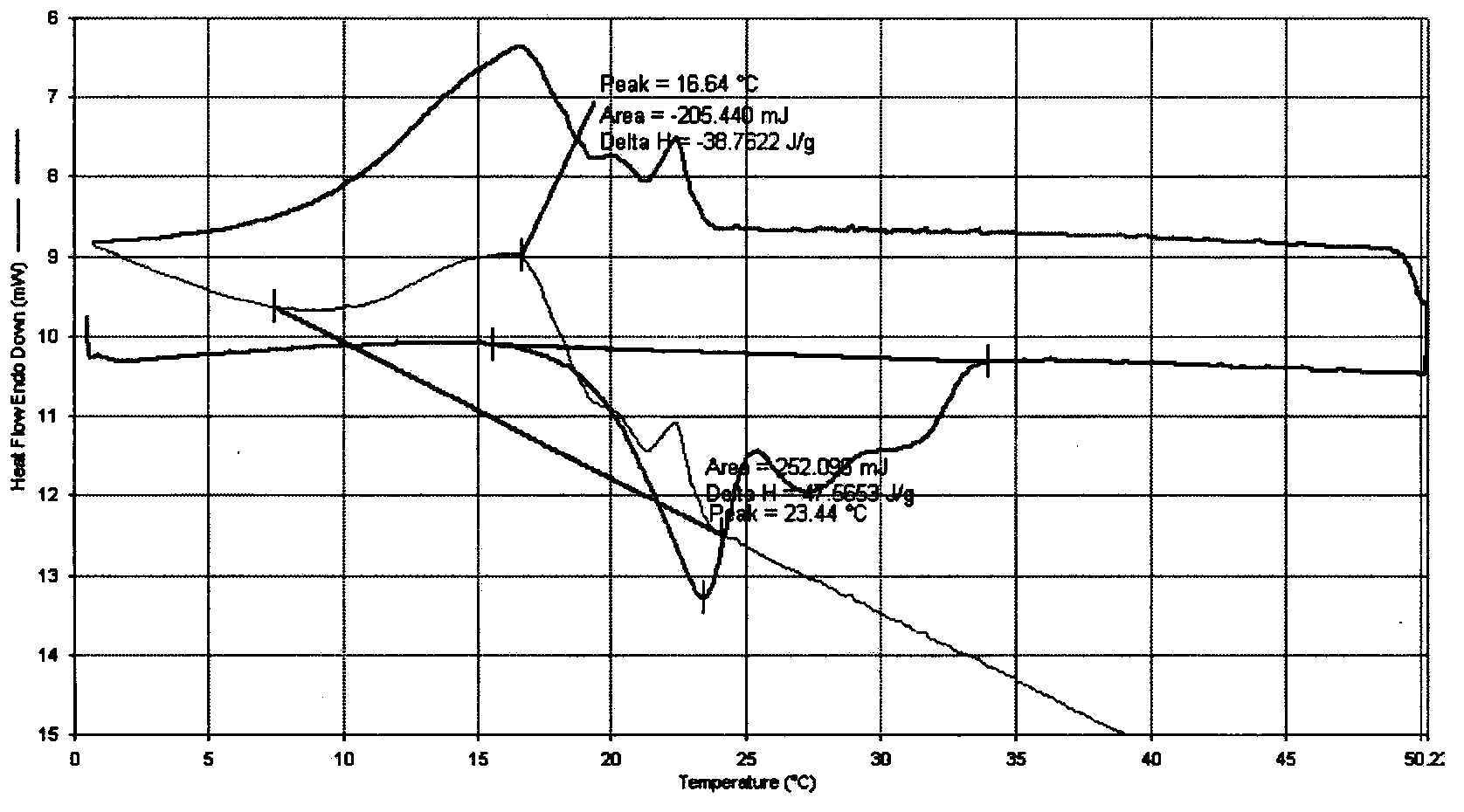

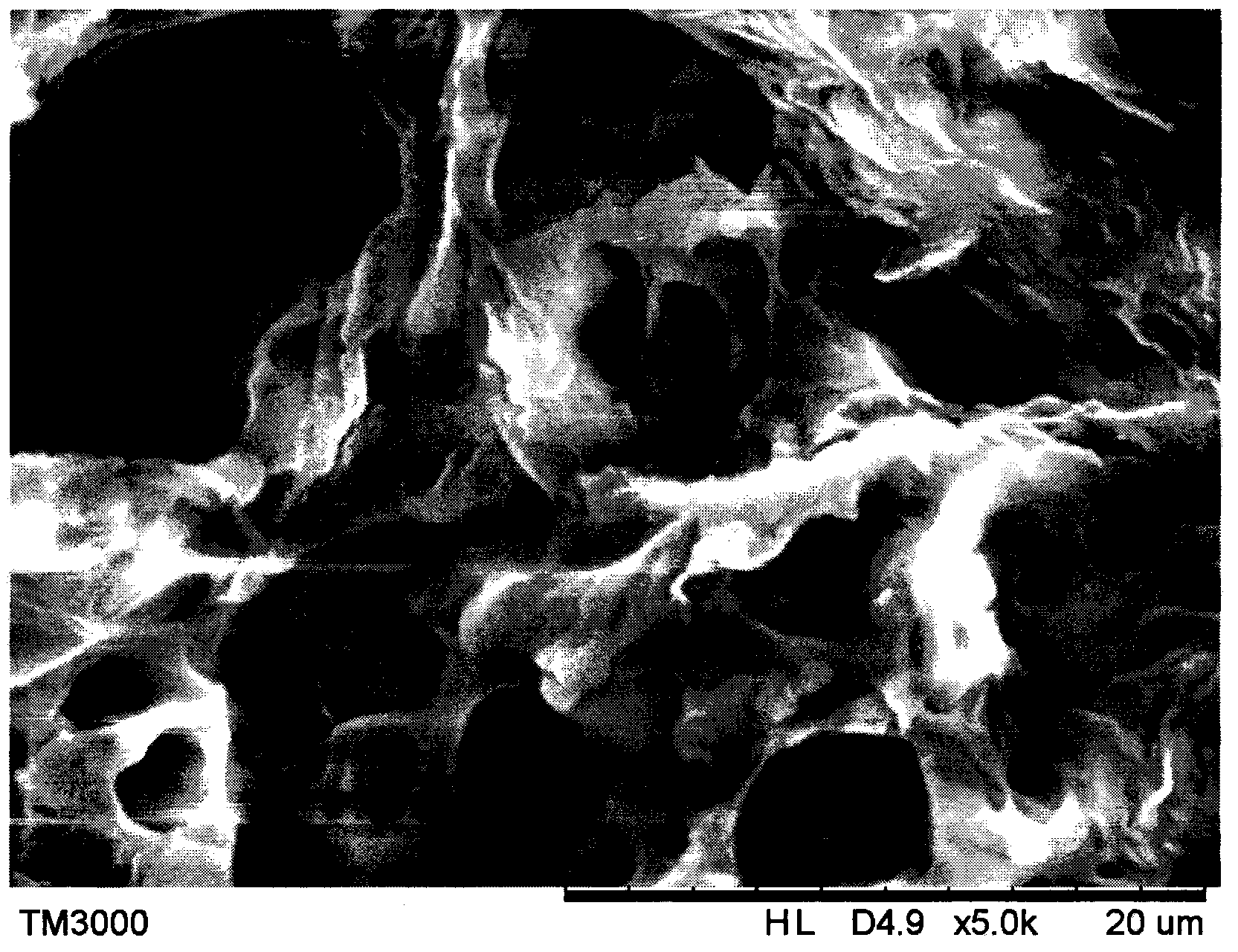

Preparation method of binary aliphatic acid/PMMA shape-stabilized phase change material

A technology for shaping phase change materials and binary fatty acids, which is applied in heat exchange materials, chemical instruments and methods to achieve the effects of high phase change enthalpy, low corrosiveness and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, 50 mL of MMA (methyl methacrylate) was washed with 5% sodium hydroxide solution several times, and then distilled under reduced pressure for later use.

[0023] In the second step, take 2.5g of CA (capric acid) and 2.5g of LA (lauric acid) into the beaker and seal it, put it in an oven at 80°C for two hours, shake it in an ultrasonic water bath at 50°C for 5 minutes, and then put it in an oven at 50°C in spare.

[0024] The third step is to take 5.5mL of refined MMA and add it to a three-necked flask. One end is connected to a condenser, and the other end is connected to nitrogen gas. First pass nitrogen gas for 3 minutes, then add 0.05g AIBN (azobisisobutyronitrile), and stir in a water bath at 80°C for 25 minutes until a sticky grout forms.

[0025] The fourth step is to remove the heat source, quickly cool down to 50°C, pour the molten dibasic fatty acid into the flask, stir vigorously for 5 minutes, and then pour it into a mold and seal it.

[0...

Embodiment 2

[0029] In the first step, 50 mL of MMA was washed with 5% sodium hydroxide solution several times, and then distilled under reduced pressure for subsequent use.

[0030] In the second step, 2g of CA and 3g of LA were added into a beaker and sealed, placed in an oven at 80°C for two hours, shaken in an ultrasonic water bath at 50°C for 5 minutes, and then placed in an oven at 50°C for later use.

[0031] The third step is to take 5.5mL of refined MMA and add it to a three-necked flask, connect a condenser tube at one end, and nitrogen gas at the other end. First pass nitrogen gas for 3 minutes, then add 0.05g AIBN, and stir in a water bath at 80°C for 25 minutes until a viscous slurry is formed.

[0032] The fourth step is to remove the heat source, quickly cool down to 50°C, pour the molten dibasic fatty acid into the flask, stir vigorously for 5 minutes, and then pour it into a mold and seal it.

[0033] The fifth step is to seal the mold and keep it in a 60°C water bath for ...

Embodiment 3

[0036] In the first step, 50 mL of MMA was washed with 5% sodium hydroxide solution several times, and then distilled under reduced pressure for subsequent use.

[0037] In the second step, 1.2g of CA and 1.8g of LA were added into a beaker and sealed, placed in an oven at 80°C for two hours, shaken in an ultrasonic water bath at 50°C for 5 minutes, and then placed in an oven at 50°C for use.

[0038] The third step is to take 7.5mL of refined MMA and add it to a three-necked flask, connect a condenser tube at one end, and nitrogen gas at the other end. First pass nitrogen gas for 3 minutes, then add 0.07g AIBN, and stir in a water bath at 80°C for 25 minutes until a viscous thin slurry is formed.

[0039] The fourth step is to remove the heat source, quickly cool down to 50°C, pour the molten dibasic fatty acid into the flask, stir vigorously for 5 minutes, and then pour it into a mold and seal it.

[0040] The fifth step is to seal the mold and keep it in a 60°C water bath f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com