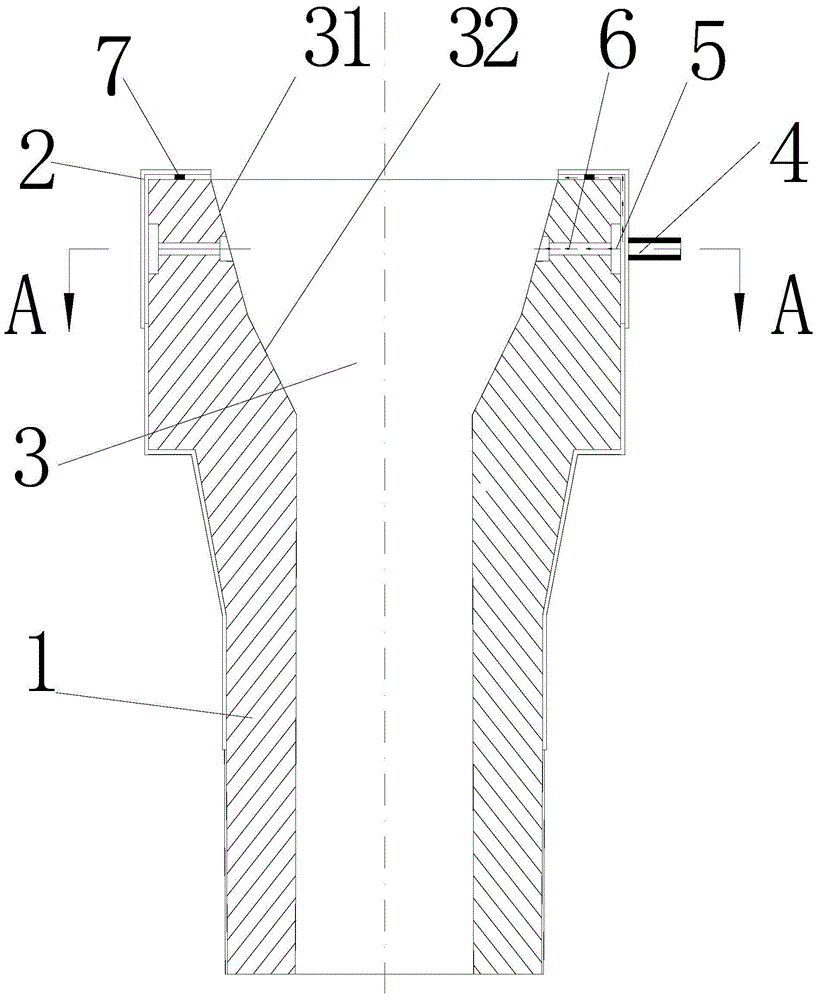

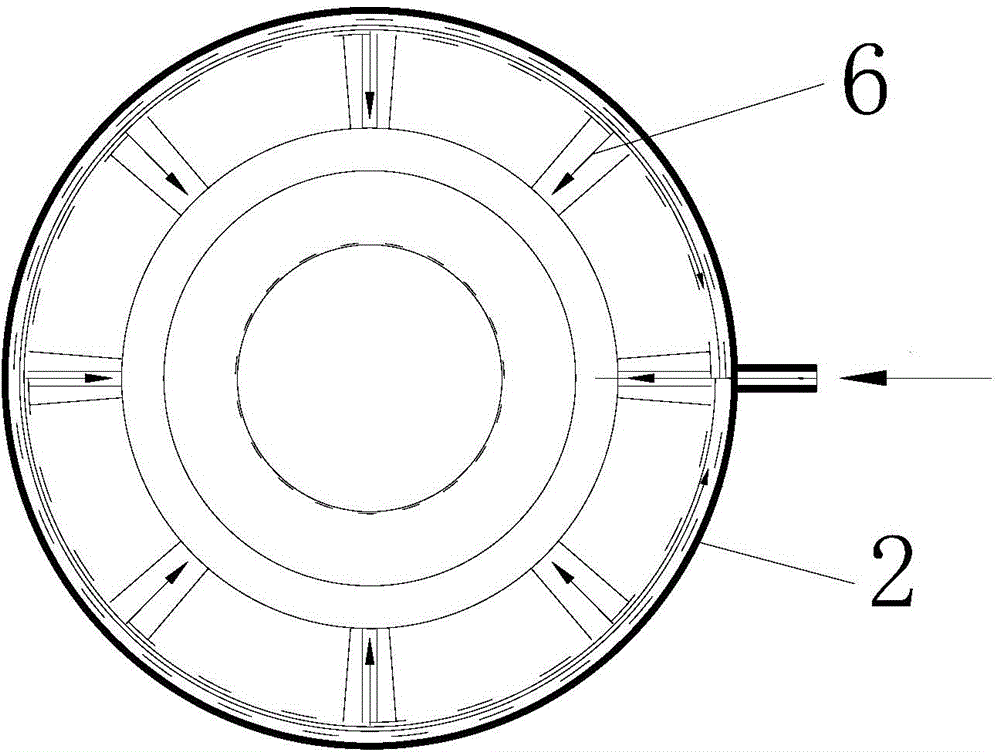

Long nozzle and continuous casting method

A long nozzle and air inlet technology, which is applied in the field of metallurgy, can solve the problems of poor sealing effect and severe nitrogen increase in molten steel, and achieve the effects of good sealing performance, improved molten steel quality, and reduced nitrogen increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Using the method for continuous casting at the long nozzle of the present invention, the tundish is cleaned with argon gas after the tundish is baked, and before the molten steel descends from the ladle to the tundish, the tundish is cleaned between the long nozzle and the ladle lower nozzle. Add sealing gaskets, open the long nozzle argon blowing valve, and adjust the long nozzle argon blowing flow to 40m 3 / h, at this time, open the ladle nozzle slide plate to make the molten steel flow from the ladle to the tundish. Take the steel sample in the ladle before hoisting the ladle to the rotary table for testing. The nitrogen content of the molten steel is 36ppm. After the molten steel flows into the tundish, remove the steel sample in the tundish for testing. Nitrogen increase is 3ppm.

Embodiment 2

[0052] Using the method for continuous casting at the long nozzle of the present invention, the tundish is cleaned with argon gas after the tundish is baked, and before the molten steel descends from the ladle to the tundish, the tundish is cleaned between the long nozzle and the ladle lower nozzle. Add sealing gaskets, open the long nozzle argon blowing valve, and adjust the long nozzle argon blowing flow to 50m 3 / h, at this time, open the ladle nozzle slide plate to make the molten steel flow from the ladle to the tundish. Take the steel sample in the ladle before hoisting the ladle to the rotary table for testing. The nitrogen content of the molten steel is 25ppm. After the molten steel flows into the tundish, remove the steel sample in the tundish for testing. Nitrogen increase is 2ppm.

Embodiment 3

[0054] Using the method for continuous casting at the long nozzle of the present invention, the tundish is cleaned with argon gas after the tundish is baked, and before the molten steel descends from the ladle to the tundish, the tundish is cleaned between the long nozzle and the ladle lower nozzle. Add a sealing gasket, open the argon blowing valve on the long nozzle pipeline, and adjust the argon blowing flow rate of the long nozzle to 60m 3 / h, at this time, open the ladle nozzle slide plate to make the molten steel flow from the ladle to the tundish. Take the steel sample in the ladle before hoisting the ladle to the rotary table for testing. The nitrogen content of molten steel is 29ppm. After the molten steel flows into the tundish, remove the steel sample in the tundish for testing. The nitrogen content of molten steel is 30ppm. Nitrogen increase is 1ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com