Medicament balloon and preparation method thereof

A balloon and drug technology, which is applied in the field of medical devices, can solve the problems of low binding force between drug coating and balloon, effective drug concentration cannot be effectively guaranteed, and low drug transfer rate, so as to increase drug loading, reduce Small drug loss, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

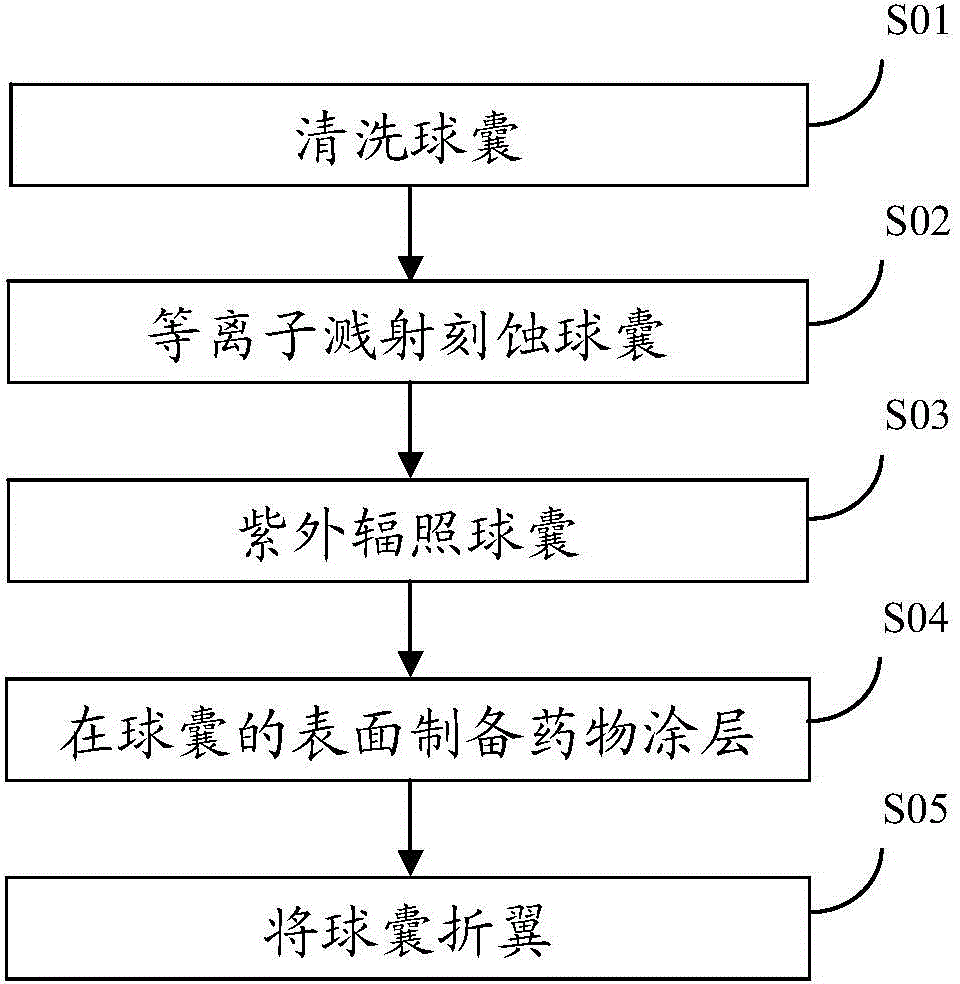

[0028] The embodiment of the present invention also provides a preparation method of the drug balloon. Such as figure 1 Shown is a flow chart of the preparation method of the drug balloon in the preferred embodiment of the present invention. The method comprises the steps of:

[0029] Step S01: cleaning the balloon.

[0030] The specific process of cleaning the balloon is as follows: the balloon is ultrasonically cleaned with alcohol, and then ultrasonically cleaned with distilled water. The balloon is dried after 2-3 washes. This application is not limited to this, the time of alcohol ultrasonic cleaning treatment and distilled water ultrasonic cleaning treatment can also be adjusted according to actual production requirements, such as extending or shortening, the order of alcohol cleaning treatment and distilled water cleaning treatment can be changed, or only alcohol can be used. Wash processing step or wash processing step with distilled water only. Since the energy e...

Embodiment 1

[0055] Cleaning the surface of the balloon: ultrasonically clean the balloon with alcohol for 5 minutes, then ultrasonically clean with distilled water for 5 minutes, the ultrasonic frequency of alcohol ultrasonic cleaning and distilled water ultrasonic cleaning is 70Hz, cycle alcohol ultrasonic cleaning and distilled water ultrasonic cleaning Dry the balloon after 2-3 passes. During the ultrasonic cleaning treatment with alcohol and the ultrasonic cleaning treatment with distilled water, keep the temperature of alcohol and distilled water not higher than 36°C. Dry the cleaned balloon and hang it on the jig for later use.

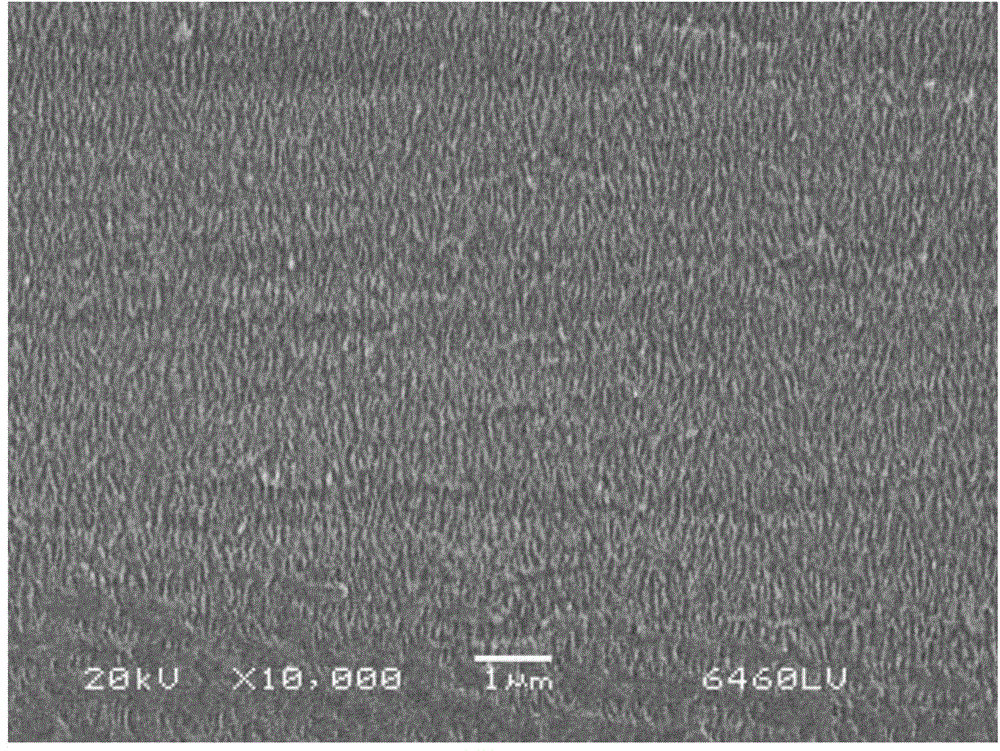

[0056] Etching the surface of the balloon by plasma sputtering: Put the fixture with the balloon in the plasma equipment, and use the bias sputtering method to etch the surface of the balloon by plasma sputtering. The specific process is as follows: when the vacuum degree of the vacuum chamber is 5Pa, oxygen gas with a purity of 99.9% is introduced, and th...

Embodiment 2

[0064]Cleaning the surface of the balloon: ultrasonically clean the balloon with alcohol for 5 minutes, then ultrasonically clean with distilled water for 5 minutes, the ultrasonic frequency of alcohol ultrasonic cleaning and distilled water ultrasonic cleaning is 20Hz, cycle alcohol ultrasonic cleaning and distilled water ultrasonic cleaning The balloon was dried after 2 passes. During the ultrasonic cleaning treatment with alcohol and the ultrasonic cleaning treatment with distilled water, keep the temperature of alcohol and distilled water not higher than 36°C. Dry the cleaned balloon and hang it on the jig for later use.

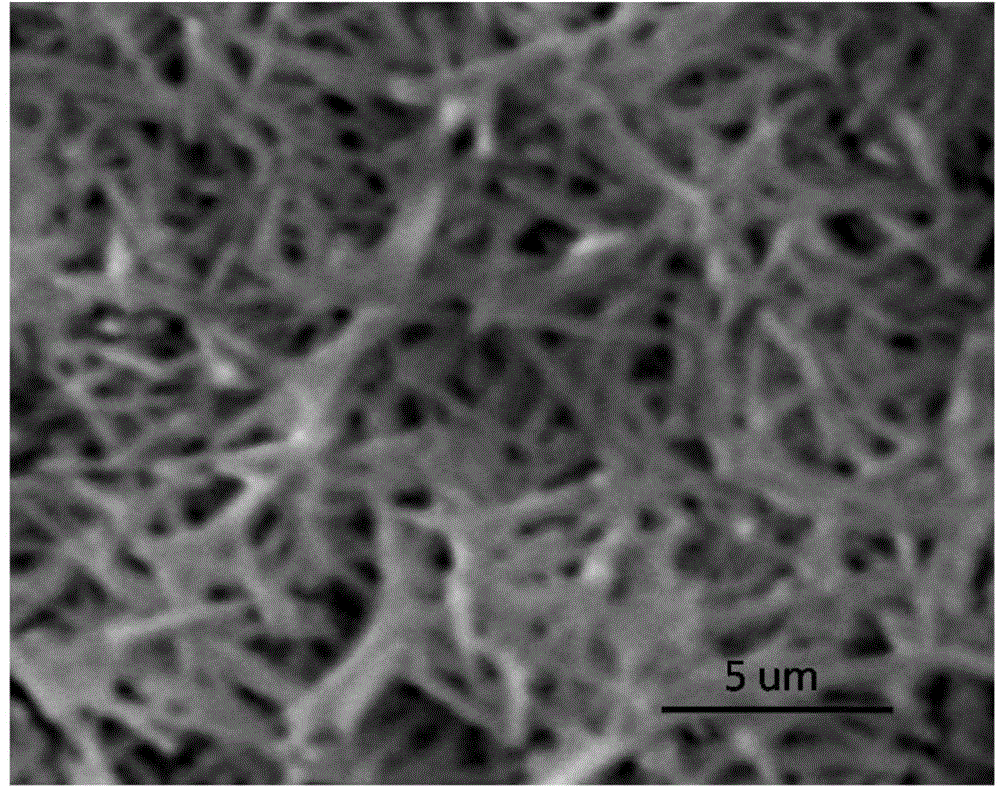

[0065] Etching the surface of the balloon by plasma sputtering: Put the jig with the balloon in the plasma equipment, and use the DC sputtering method to etch the surface of the balloon by plasma sputtering. The specific process is as follows: when the vacuum degree of the vacuum chamber is 5 Pa, argon gas with a purity of 99.9% is introduced, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com