Jet layup board-producing system

A liquid level control and blanket technology, applied in textiles and papermaking, paper machines, papermaking, etc., can solve the problems of color waste, uneven spraying, and inability to filter slurry, so as to improve the quality of formation and smoothness , The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

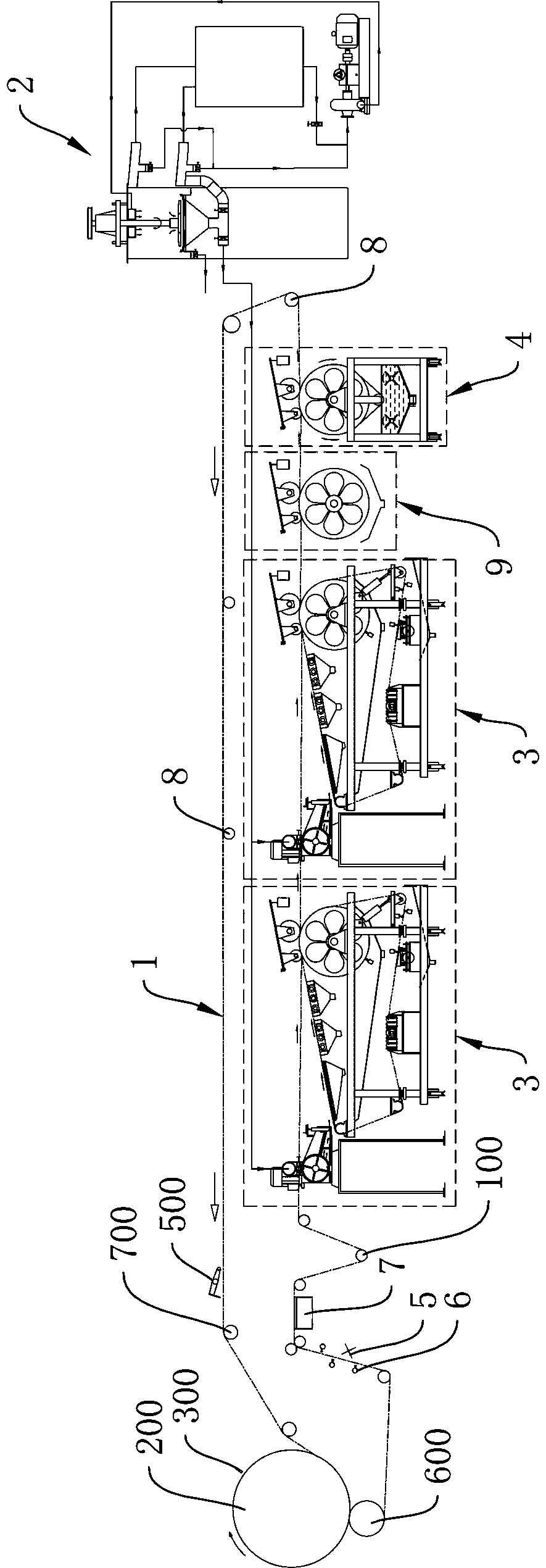

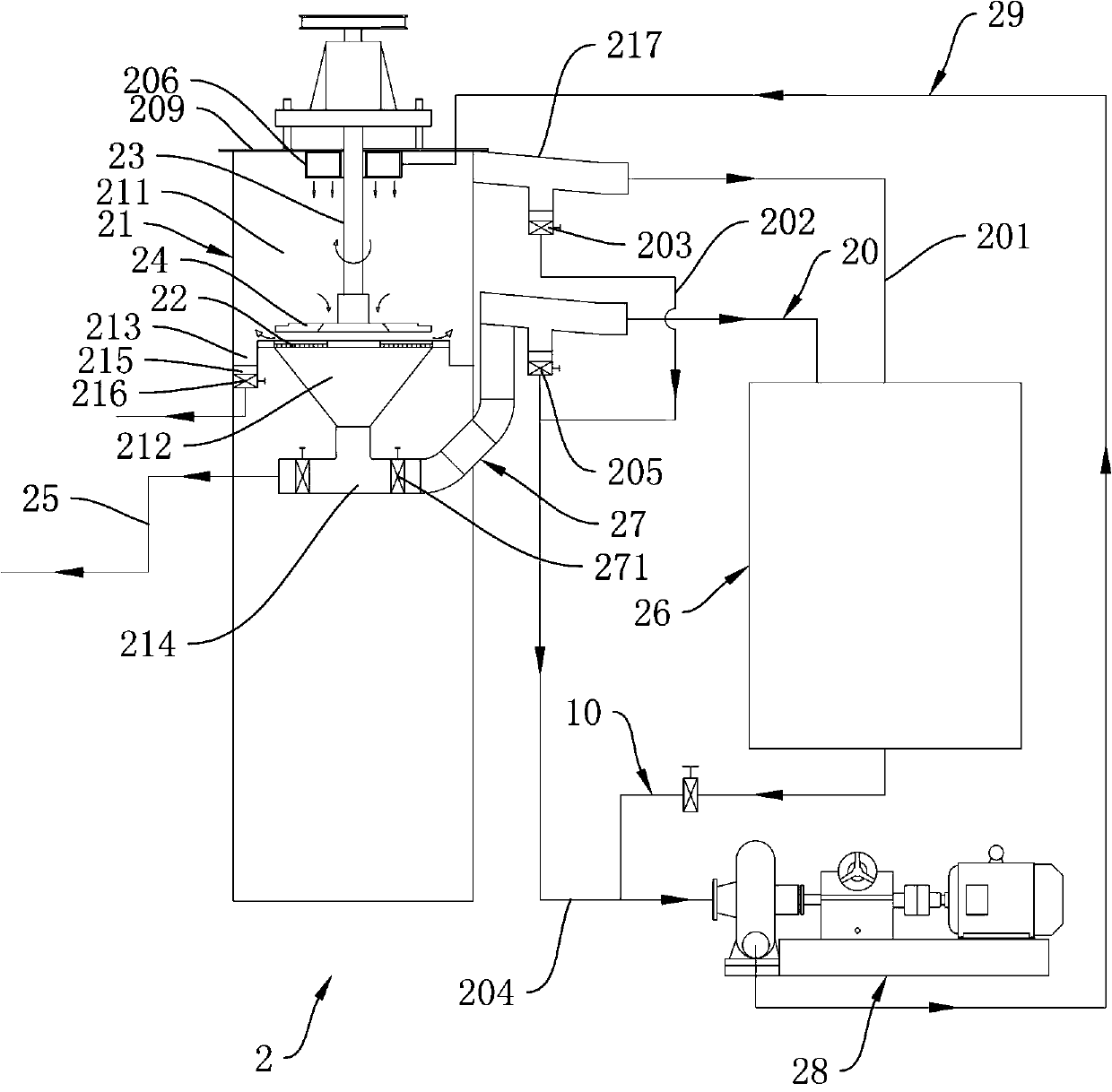

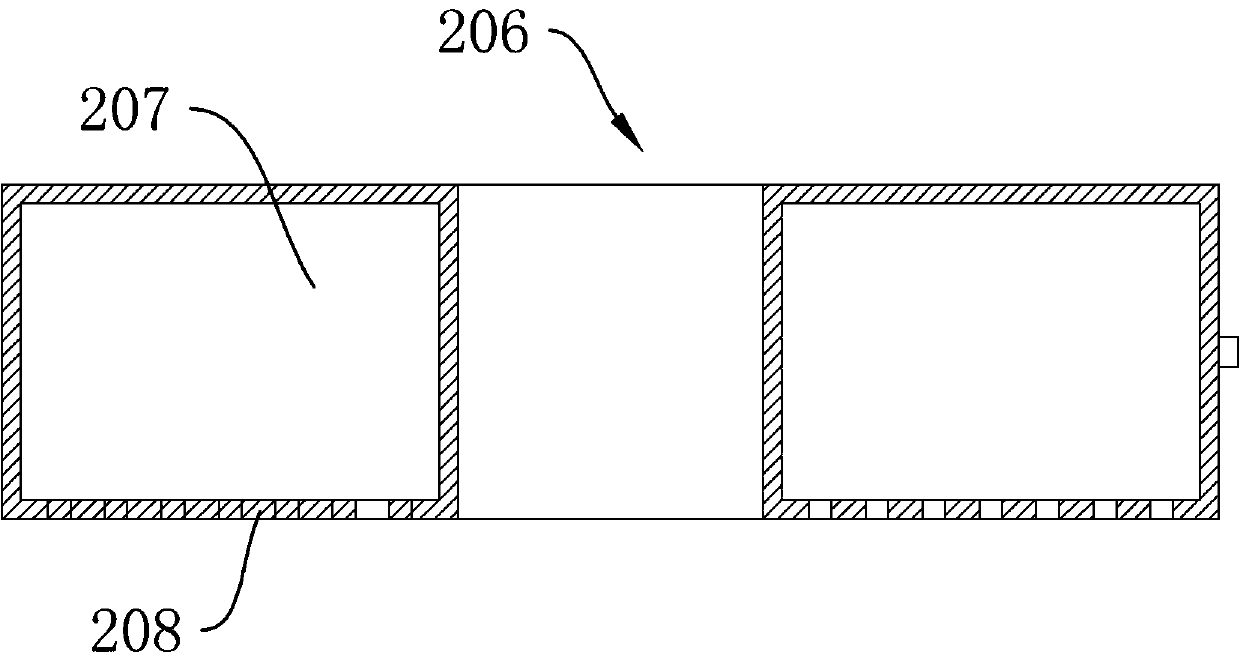

[0029] Such as figure 1 As shown, a jet lay-up board system according to the present invention includes a felt 1, a slurry stabilization filter tank 2, several jet spread forming machines 3, a colorant adding machine 4, a cloth beater 5, and a felt washing assembly 6 , vacuum suction box 7, some backing rollers 8, wherein, such as figure 1 As shown, each backing roller 8 is longitudinally arranged, and the felt 1 is wound on the backing roller 8; as figure 2 As shown, the slurry stabilizing filter tank 2 is arranged on the side of the felt 1, and the slurry stabilizing filter tank 2 includes a filter tank 21, a filter sieve plate 22, a stirring shaft 23, a stirring impeller 24, a slurry delivery pipe 25, a slurry storage Tank 26, liquid level control pipe 27, feed pump 28, discharge pipe 29, raw material pipe 10, slurry guide pipe 20, the top of the filter tank 21 is provided with a first stirring chamber 211, the first stirring chamber 211 The bottom of the chamber is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com