Method for preparing nano-metallic film on surface of liquid phase and application of method in recovery of metal in wastewater

A technology of nano metal film and nano metal particles, applied in the field of nano materials, can solve the problems of high resin price and large dosage, and achieve the effects of convenient method, simple operation and avoidance of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Chlorauric acid (HAuCl 4 ) solution and PVP solution are mixed in the reaction vessel with chloroauric acid: PVP=1:100mol / g, place between two electrode plates of the plasma, airtight, the vacuum chamber is evacuated, then filled with argon for discharge The gas is maintained at a pressure of 200Pa, an AC voltage of 500V is applied to the electrode, and the plasma is reduced by glow discharge, the plasma temperature is 50°C, and the reduction time is 30s. The sample forms a layer of nano gold film on the surface of the liquid phase. The film takes on different colors when the incident light hits it from different angles. It is confirmed by transmission electron microscopy that the particle size is 10-30nm, and the nano-gold thin film can be used in the fields of optics and catalysis.

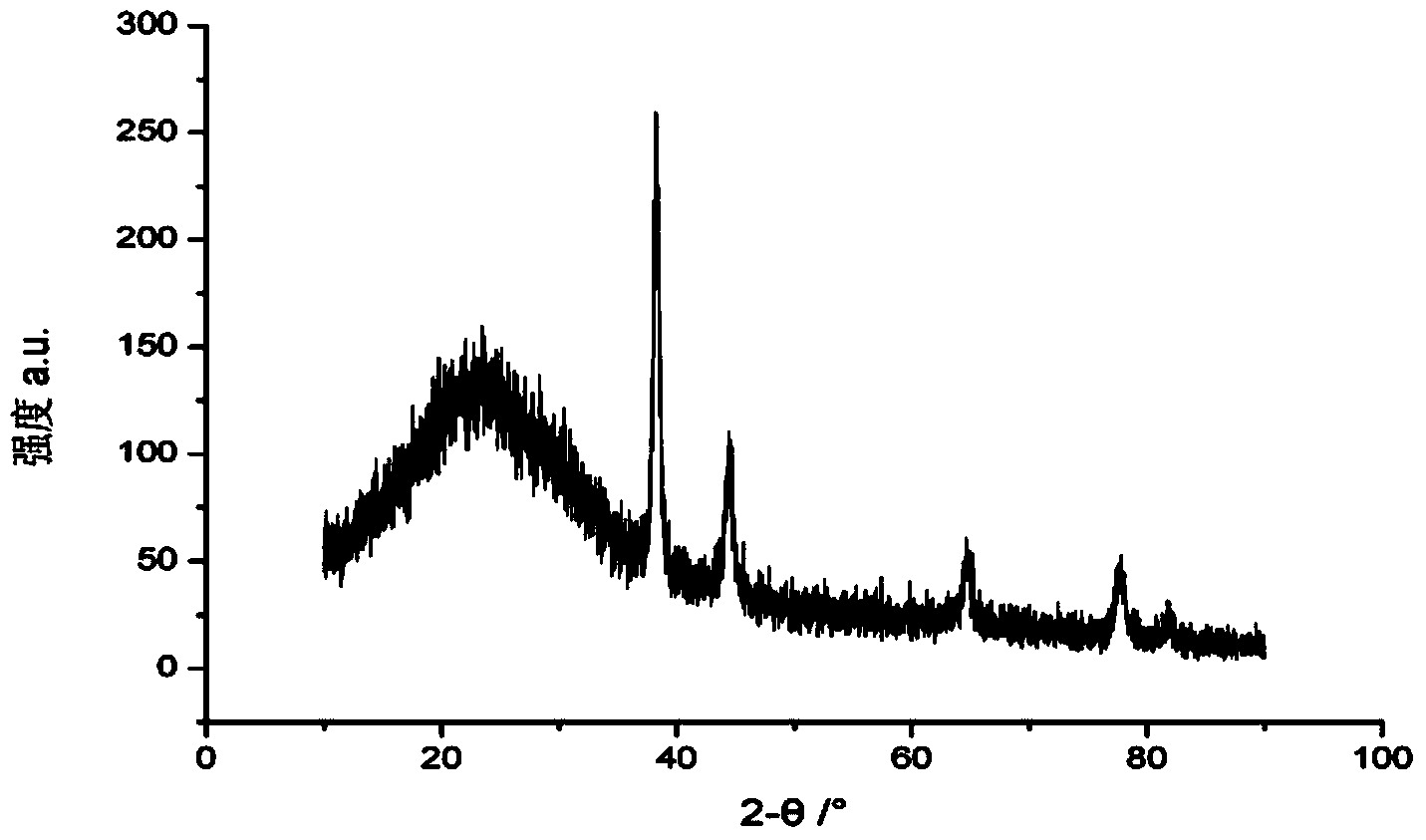

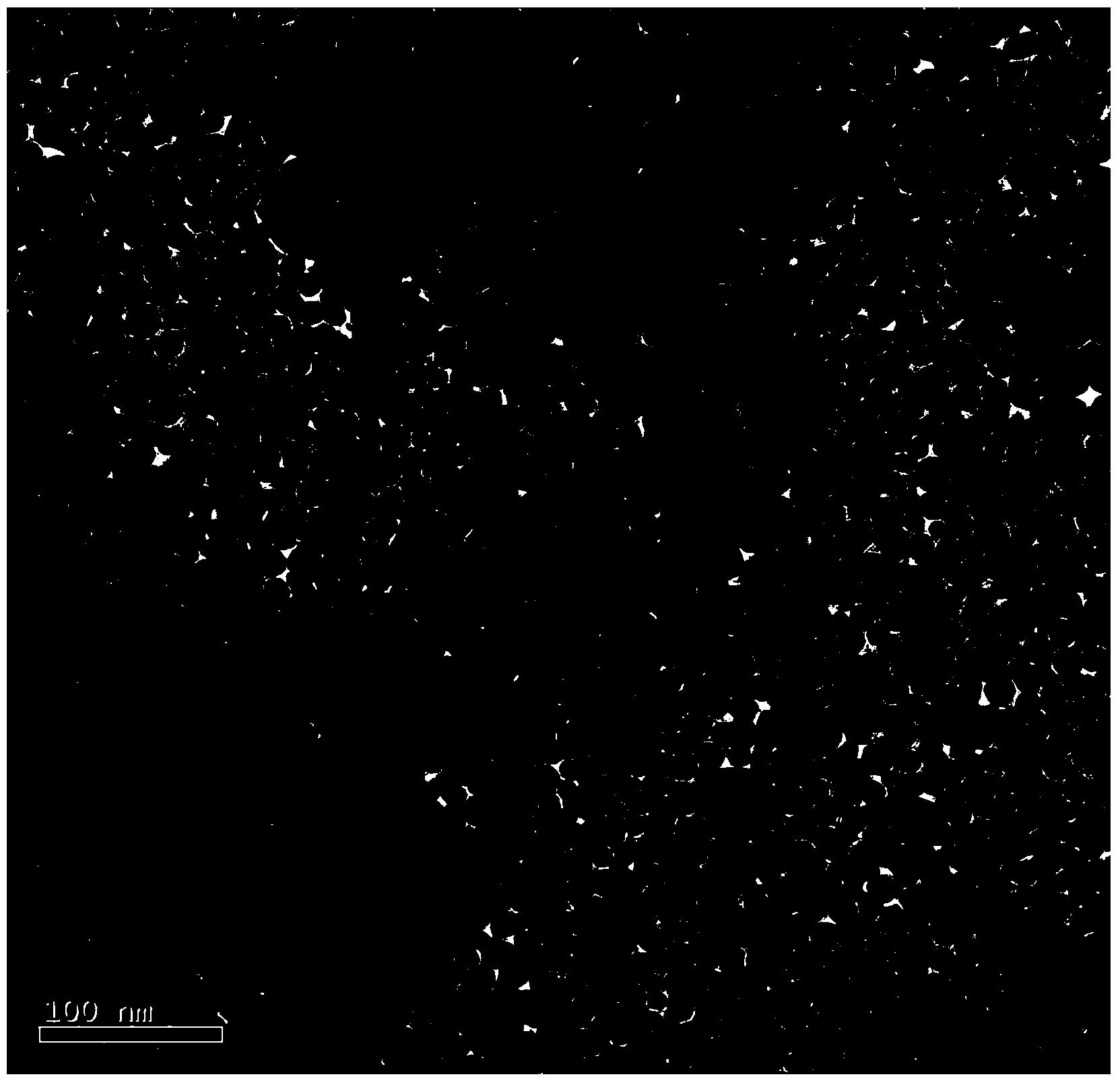

[0038] The prepared nano-gold film is analyzed by X-ray diffraction and scanning electron microscope, and the following analysis results can be obtained:

[0039] Such as figure 1 As ...

Embodiment 2

[0042] silver nitrate (AgNO 3 ) solution and the PVP solution are mixed in the reaction vessel with silver nitrate: PVP=1:667mol / g, then placed between the two electrode plates of the plasma discharger, airtight, the vacuum chamber is evacuated, and then filled with argon As discharge gas, maintain a pressure of 200Pa, apply an AC voltage of 500V on the electrode, and use glow discharge plasma to reduce silver nitrate (AgNO 3 ), the temperature of the plasma is 40° C., the reduction time is 3 min, and a nano-silver thin film floating on the surface of the liquid phase is prepared. When the incident light shines from different angles, it will show different colors. It is confirmed by transmission electron microscopy that the particle size is 3-20nm, and the nano-silver thin film can be applied to the fields of optics and catalysis.

[0043] Such as image 3 The actual photos of the experimental results are shown. From the figure, it can be clearly seen that there is a thin fil...

Embodiment 3

[0047] Chlorauric acid (HAuCl 4 ) and the same concentration of copper sulfate (CuSO 4 ) mixed solution and PVP solution are mixed with chloroauric acid: PVP=1:500mol / g in reaction container, then place between two electrode plates of plasma, airtight, vacuum chamber is evacuated, then fills with argon As a discharge gas, maintain a pressure of 200Pa, apply an AC voltage of 500V to the electrodes, and use glow discharge plasma for reduction. The plasma temperature is 50°C and the reduction time is 6 minutes. It is confirmed by X-ray diffraction that the thin film obtained by reduction is a thin film of gold, and copper ions are not reduced. The remaining liquid was tested by ICP. After one glow process, the remaining gold ion concentration was 0.00111mol / L, and the copper ion concentration was 0.001473mol / L. Part of the copper element adheres to the film in the form of ions, and can be eluted with water and returned to the mother liquor. After multiple glow processes, gold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com