Maleopimaric acid modified polysiloxane resin and preparation method thereof

A technology of polysiloxane resin and maleopimaric acid, which is applied in the field of maleopimaric acid modified polysiloxane resin and its preparation, can solve problems such as poor adhesion and low mechanical strength, and achieve improved water resistance and reduced The effect of simple production cost and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 100g octamethylcyclotetrasiloxane, 20g tetramethyltetravinylcyclotetrasiloxane, 34g aminopropylmethyldiethoxysilane, 10g hexamethyldisiloxane and 0.2 g potassium hydroxide, stirred and reacted at 100°C for 8 hours, then gradually warmed up to 180°C, vacuumized to remove low boilers; cooled to 120°C, added 72g maleopimaric acid (purity is 98%), stirred and reacted for 4 hours Afterwards, heat up to 180°C and vacuumize to remove low boilers; collect the maleopimaric acid-modified silicone resin while it is hot under the protection of nitrogen.

Embodiment 2

[0039] Add 206g of octamethylcyclotetrasiloxane, 20g of tetramethyltetravinylcyclotetrasiloxane, 10g of hexamethyldisiloxane and 0.2g of potassium hydroxide in the reaction kettle, and stir the reaction at 100°C for 8 Hours, then gradually raise the temperature to 180°C, vacuumize to remove low boilers; collect the silicone resin while it is hot under the protection of nitrogen.

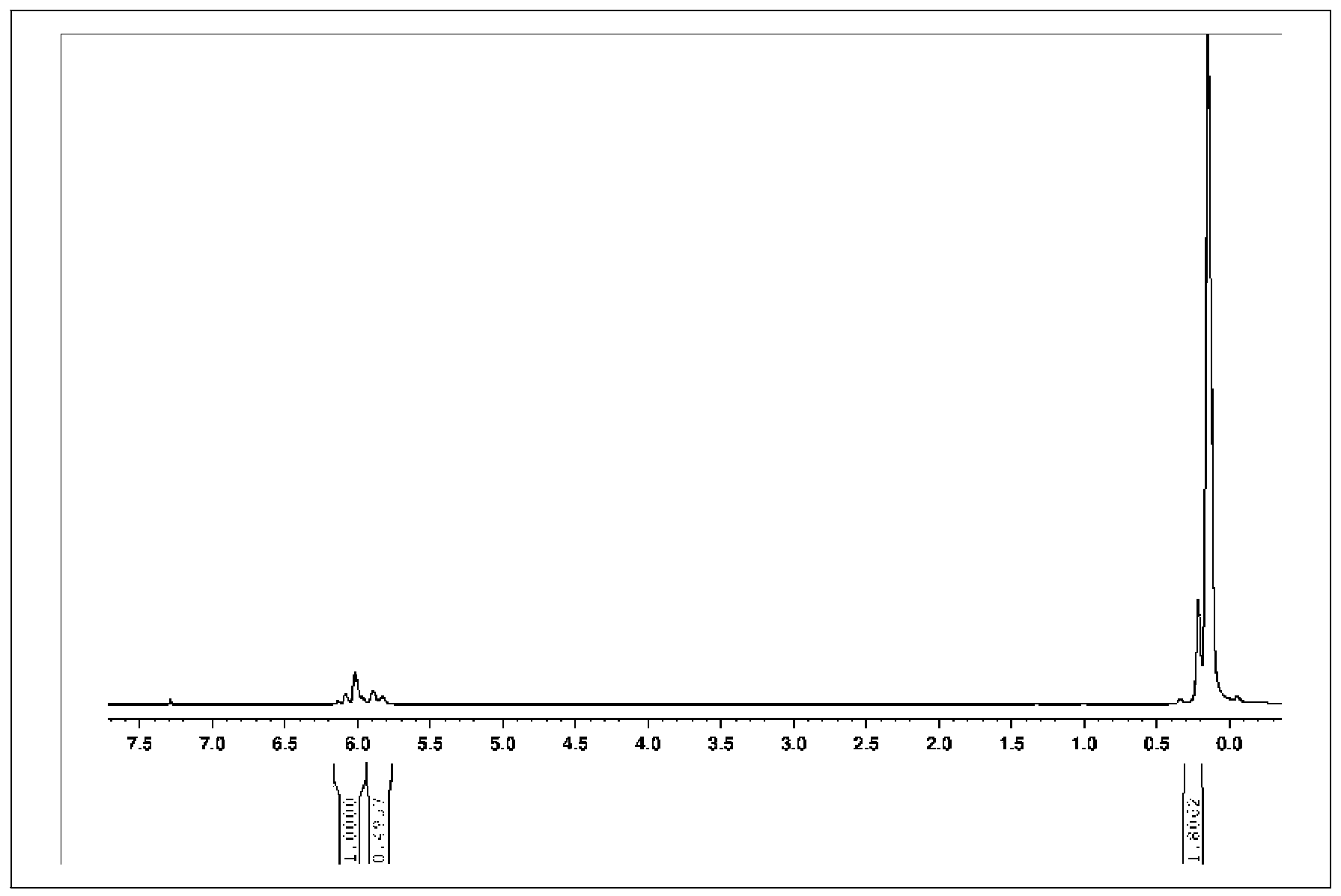

[0040] Depend on figure 2 As can be seen, by the organosilicon resin prepared by example 2 1 The HNMR spectrogram peaks are relatively simple, within the range of 0.5-3.0ppm is the absorption peak of the proton on Si-CH3, and above 5.5ppm appears as the absorption peak of the proton on the vinyl Si-CH=CH2, the resulting product structural formula is:

[0041]

[0042] Among them, m 1 =44,m 2 =4.

[0043] Depend on figure 1 It can be seen that, in addition to the Si-CH of ordinary vinyl silicone resin 3 (0.5~3.0ppm) and Si-CH=CH 2 (5.7 ~ 6.2ppm) chemical shift peaks, maleopimaric acid modifie...

Embodiment 3

[0052] Modified 100 parts of methyl vinyl silicone rubber raw rubber (the molar content of vinyl units is 0.11%, and the molar mass is 800,000 g / mol), 4 parts of hydroxyl silicone oil (viscosity 100 Pa·S), 6 parts of maleopimaric acid Silicone resin (gained in embodiment 1) and 25 parts of fumed white carbon black Knead evenly in a kneader; after the rubber material is cooled to room temperature, add 1 part of vulcanizing agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane into the open mill to make the rubber The material is mixed evenly.

[0053] Put the above-mentioned rubber into the mold, pressurize and vulcanize on a flat vulcanizer for 30 minutes, and the vulcanization temperature is 170±2°C; remove the pressure and take out the sample; keep warm in an aging oven at 200°C for 4 hours; naturally cool to room temperature, and obtain a mixture Mixing film 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com