Anti-scaffolding composite coating

A composite coating, anti-nodulation technology, applied in the direction of layered products, metal layered products, furnace types, etc., can solve the problems of increased nodulation and wear, high possibility of oxidation, disadvantage of high-quality steel plates, etc. Achieve the effect of reducing processing and manufacturing costs, prolonging service life, and good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

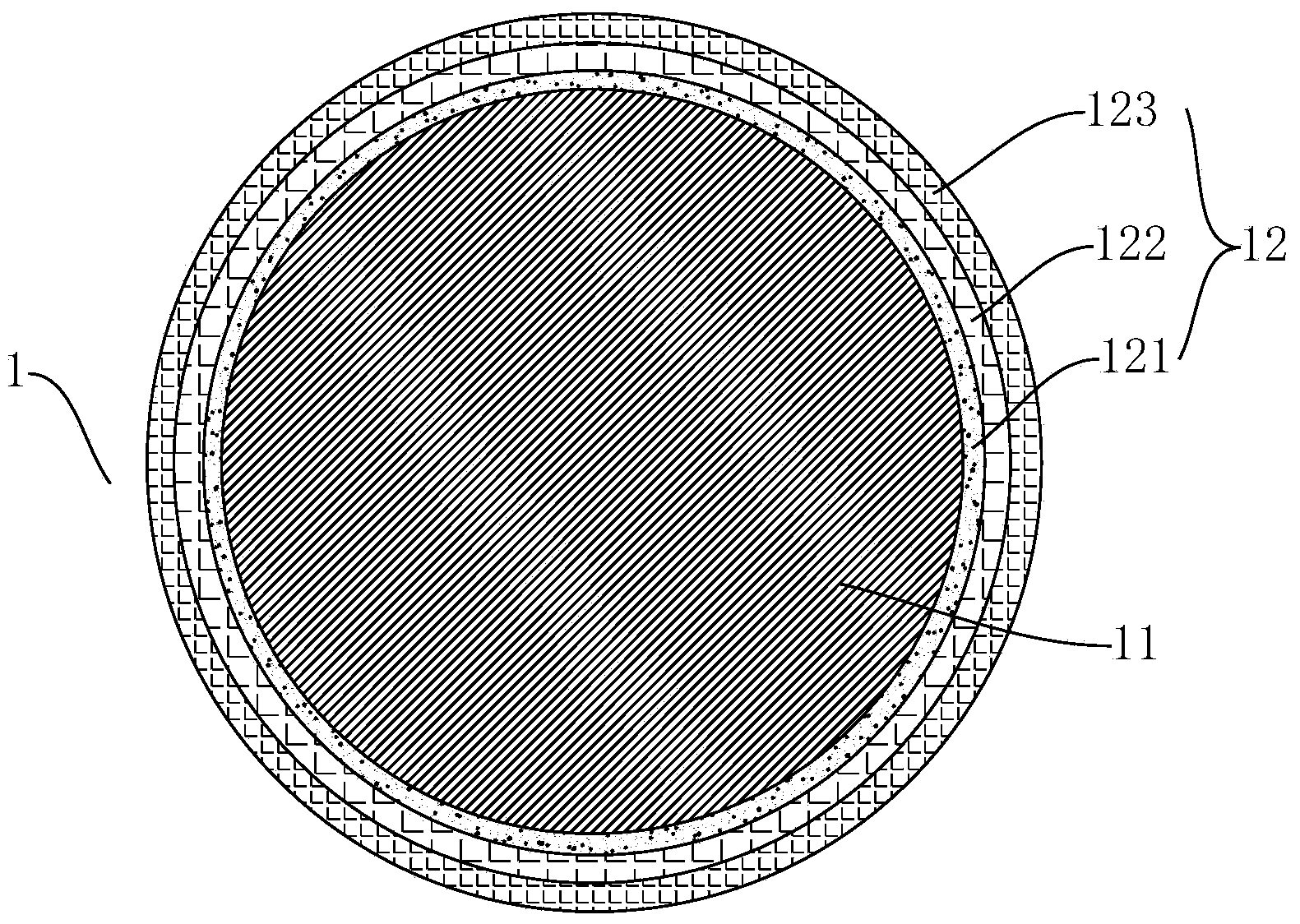

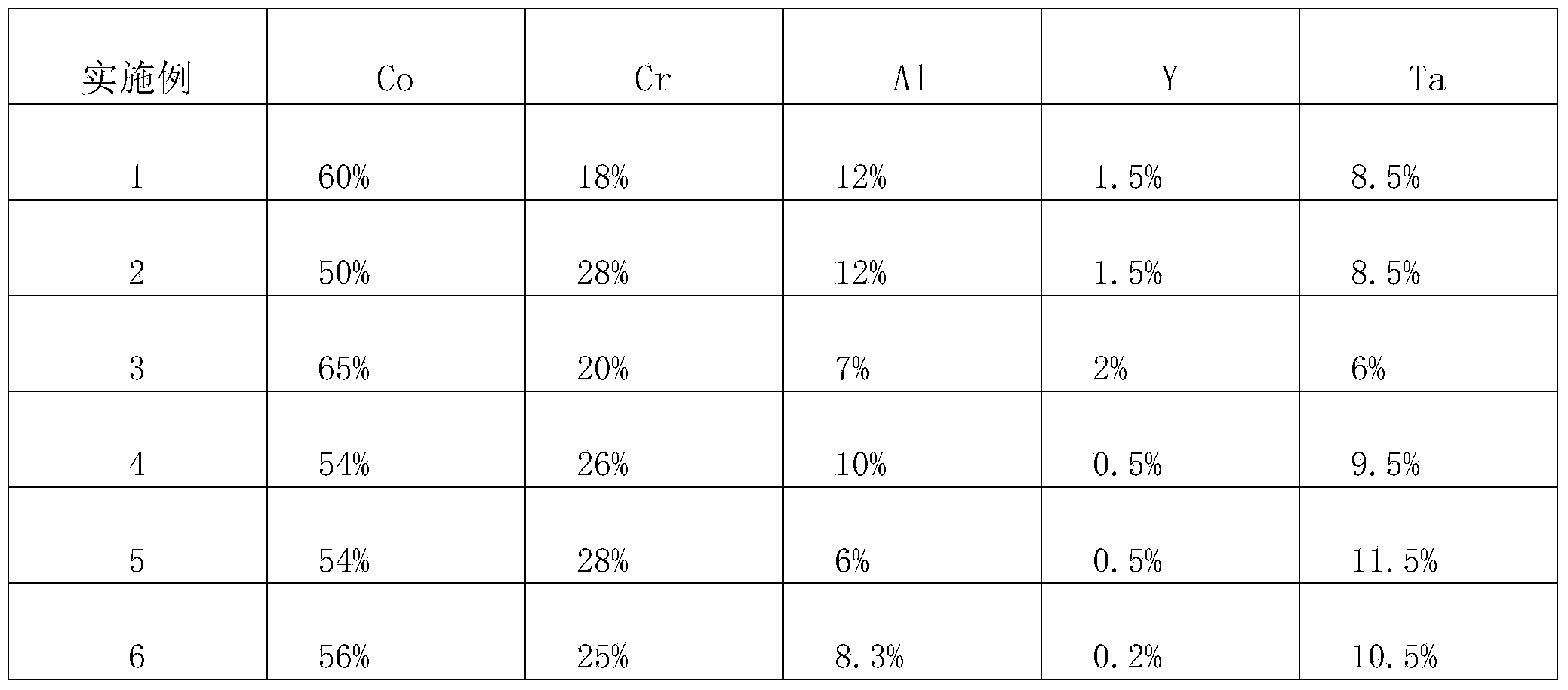

[0028] Such as figure 1 and 2 Shown, is composite structure roll 1. The composite structure roll 1 includes a substrate 11 and an anti-nodulation composite coating 12 covering the surface of the substrate. The base body 11 is the traditional annealing furnace roller. The anti-nodulation composite coating 12 includes three layers of sub-coatings, which are respectively an alloy layer 121 coated on the surface of the substrate, a first cermet layer 122 coated on the surface of the alloy layer 121, and a first cermet layer 122 coated on the surface of the alloy layer 121. The second cermet layer 123 on the surface. The composition weight percentage content of the alloy layer 121 of the anti-nodulation composite coating 12 in each embodiment is shown in Table 1:

[0029] Table I

[0030]

[0031]

[0032] The composition weight percentage content of the first cermet la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com