High polymer-modified metal organic framework material composite membrane, and preparation and application thereof

A metal-organic framework and polymer technology, applied in fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve the problem of low proton conductivity and achieve simple preparation process, controllable structure, and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix terephthalic acid, chromium nitrate nonahydrate, hydrofluoric acid, and water in a molar ratio of 1:1:1:265 at 220 o C, under the corresponding saturated vapor pressure for 8h, with 15 o C / min rate to cool down until 40 o C, centrifugal washing, 60 o C under vacuum for 24 h to obtain a metal-organic framework material named MIL101. Weigh 1.5 g metal organic framework material into a 100 mL round bottom flask, add 90 mL nitromethane, then add 0.75 mL concentrated sulfuric acid, 2.71 mL trifluoromethanesulfonic anhydride, 30 o C was reacted for 1 h, and the metal-organic framework material modified with sulfonic acid was obtained after centrifugation and washing.

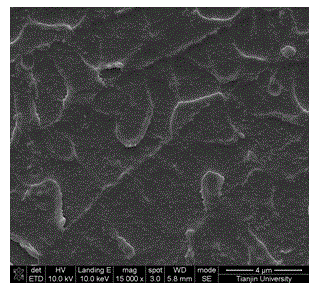

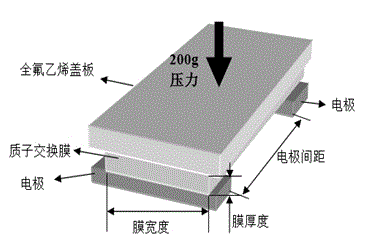

[0022] Weighed 0.015 g of metal-organic framework material modified with sulfonic acid and added it to 6 mL of nitrogen-nitrogen dimethylformamide. After dispersing for 8 h, 0.6 g of sulfonated polyether ether ketone was added to the above solution and stirred for 24 h. After degassing, pour the casting...

Embodiment 2

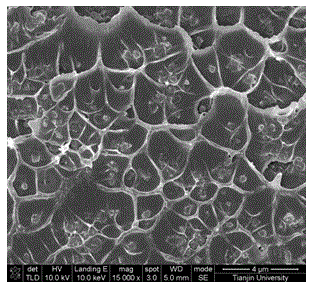

[0024] The metal organic framework material modified with sulfonic acid was prepared according to the method in Example 1. Weighed 0.030 g of metal-organic framework material modified with sulfonic acid and added it to 6 mL of nitrogen-nitrogen dimethylformamide. After dispersing for 8 h, 0.6 g of sulfonated polyether ether ketone was added to the above solution and stirred for 24 h. After degassing, pour the casting solution on a clean glass plate and place it in an oven for 60 o C for 12 h, then heated to 80 o C drying for 12 h, and finally after 120 o After C annealing treatment, the membrane was removed and placed in 2 M sulfuric acid for 24 h, and then washed repeatedly with deionized water until neutral. Finally wet the film at 60 o C and vacuum-dried for 12 h to obtain a sulfonated polyetheretherketone-metal-organic framework composite membrane (membrane 2).

Embodiment 3

[0026] The metal organic framework material modified with sulfonic acid was prepared according to the method in Example 1. Weighed 0.0450 g of metal-organic framework material modified with sulfonic acid and added it to 6 mL of nitrogen-nitrogen dimethylformamide. After dispersing for 8 h, 0.6 g of sulfonated polyether ether ketone was added to the above solution and stirred for 24 h. After degassing, pour the casting solution on a clean glass plate and place it in an oven for 60 o C for 12 h, then heated to 80 oC drying for 12 h, and finally after 120 o After C annealing treatment, the membrane was removed and placed in 2 M sulfuric acid for 24 h, and then washed repeatedly with deionized water until neutral. Finally wet the film at 60 o C and vacuum-dried for 12 h to obtain a sulfonated polyetheretherketone-metal-organic framework composite membrane (membrane 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com